Device and method integrating automatic label printing, real-time attachment and verification

An automatic printing and labeling technology, applied to labels, manual label dispensers, packaging, etc., can solve problems such as inaccurate labeling, unstable labeling action, and no two-in-one labels with barcodes and electronic chips. Achieve outstanding results in real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

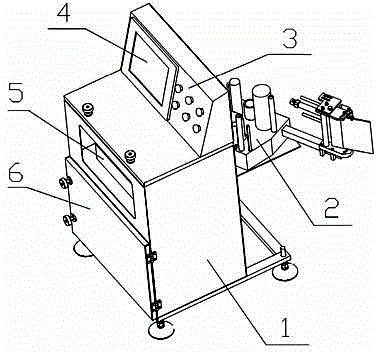

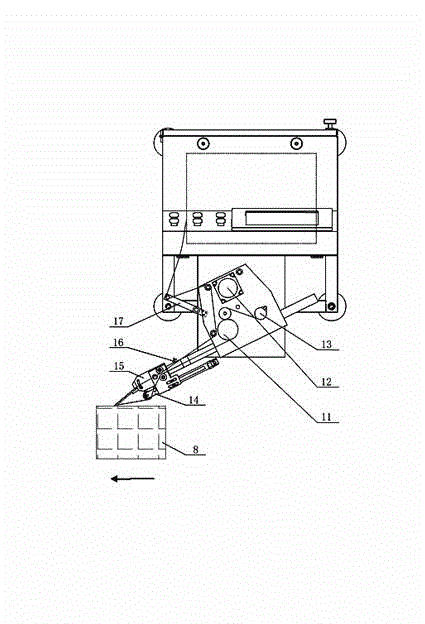

[0040] In order to facilitate the understanding of those skilled in the art, the structural principles of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0041] A method integrating automatic label printing, real-time attachment and verification, comprising the following steps:

[0042] (1) Generate RFID code according to the production batch of the product;

[0043] (2) Print the generated RFID code and / or product text and pattern on the self-adhesive label;

[0044] (3) Check whether the self-adhesive label contains RFID code and / or product text and pattern, if not, return to the second step to reprint, if yes, go to the next step;

[0045] (4) Check whether the information written on the self-adhesive label is correct, if not, return to the second step to reprint, if correct, go to the next step;

[0046] (5) Check whether the self-adhesive label is in good condition, if not, return to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com