Preparation method of hierarchical porous structure silica-alumina zeolite material

A technology of silica-alumina zeolite and multi-level pores, which is applied in the field of preparation of multi-level porous structure silica-aluminum oxide materials, and can solve the problems of difficulty in preparation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

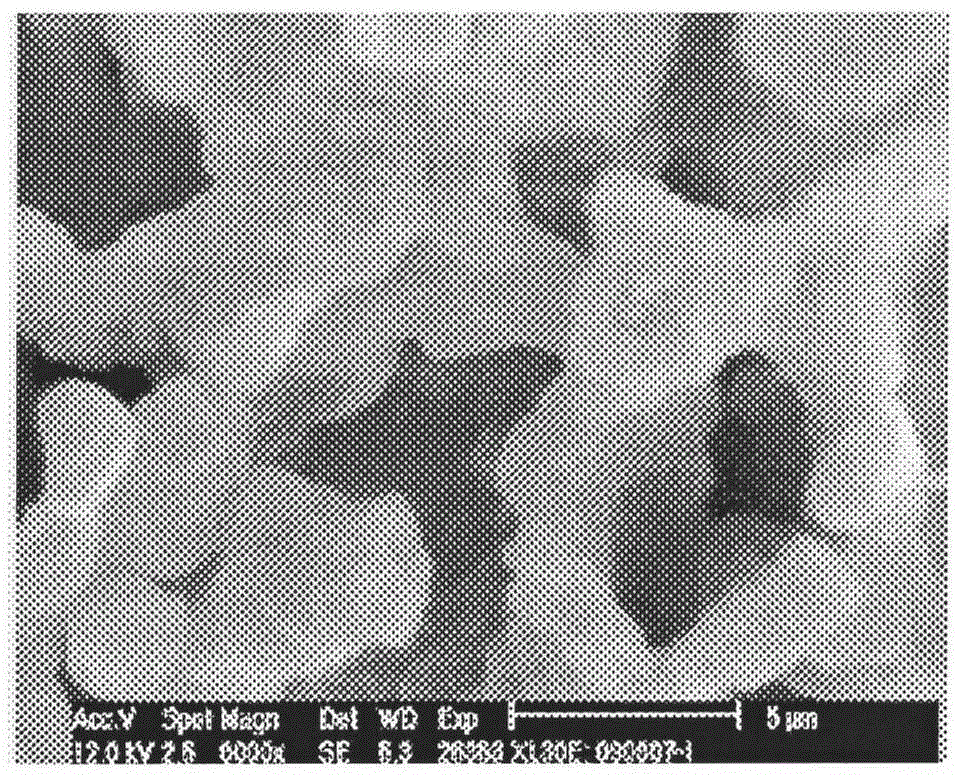

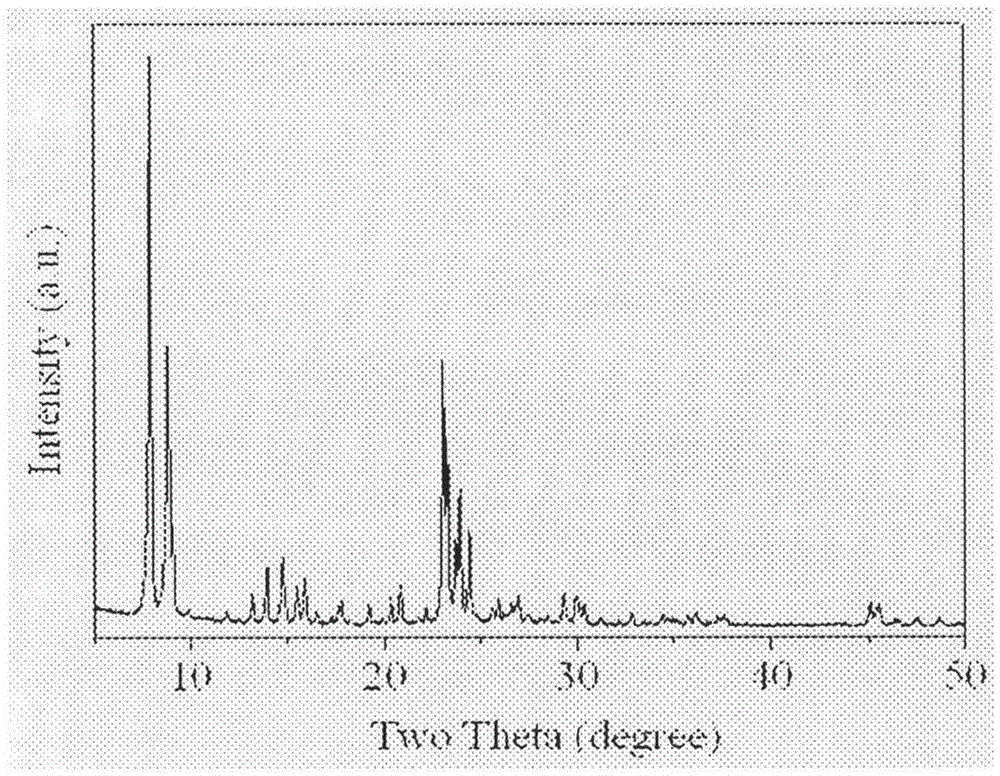

Embodiment 1

[0024] Weigh 4 grams of 1 mol / liter nitric acid solution and 5 grams of water, add 1 gram of polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 5800, referred to as P123), stir and dissolve at room temperature, and add polyethylene oxide to the mixed solution. Diol (molecular weight 10000) 0.7 grams and 1.26 grams of aluminum nitrate (Al(NO 3 ) 3 9H 2 0), after stirring evenly, transfer to the ice-water mixing bath and continue to stir for 5 minutes. 5.1 g of tetramethyl orthosilicate was added to the mixed solution, and vigorously stirred for 20 minutes. Pour the mixture into a mold to seal it, and place it in an oven at 60°C for 72 hours of aging. Remove from the mold, dry at 25°C, and finally bake at 600°C for 8 hours to obtain a silicon-aluminum oxide monolithic material with a silicon-aluminum molar ratio Si / Al=16; Tetrapropylammonium hydroxide solution was added to the bottom of the kettle, and after crystallization at 130° C. for 3 days, the sample w...

Embodiment 2

[0026]Weigh 12 grams of 0.3 mol / liter phosphoric acid solution, add 4.0 grams of polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 1500), stir and dissolve at room temperature, add polyethylene glycol (molecular weight 10000) 0.6 After stirring evenly, the mixed solution was added to the isopropanol solution containing 8.9 grams of tetrapropyl orthosilicate and 0.14 grams of aluminum isopropoxide, and vigorously stirred for 20 minutes. Pour the mixture into a mold and seal it, and place it in an oven at 80°C for 72 hours of aging. After taking it out, demoulding, drying at room temperature, and finally roasting at 550°C for 5 hours to obtain a silicon-aluminum oxide monolithic material with a silicon-aluminum molar ratio Si / Al=75; then place the silicon-aluminum oxide monolithic material on the upper part of the reactor, and Tetrapropylammonium hydroxide solution was added at the bottom, and after crystallization at 130°C for 3 days, the sample was washed, dri...

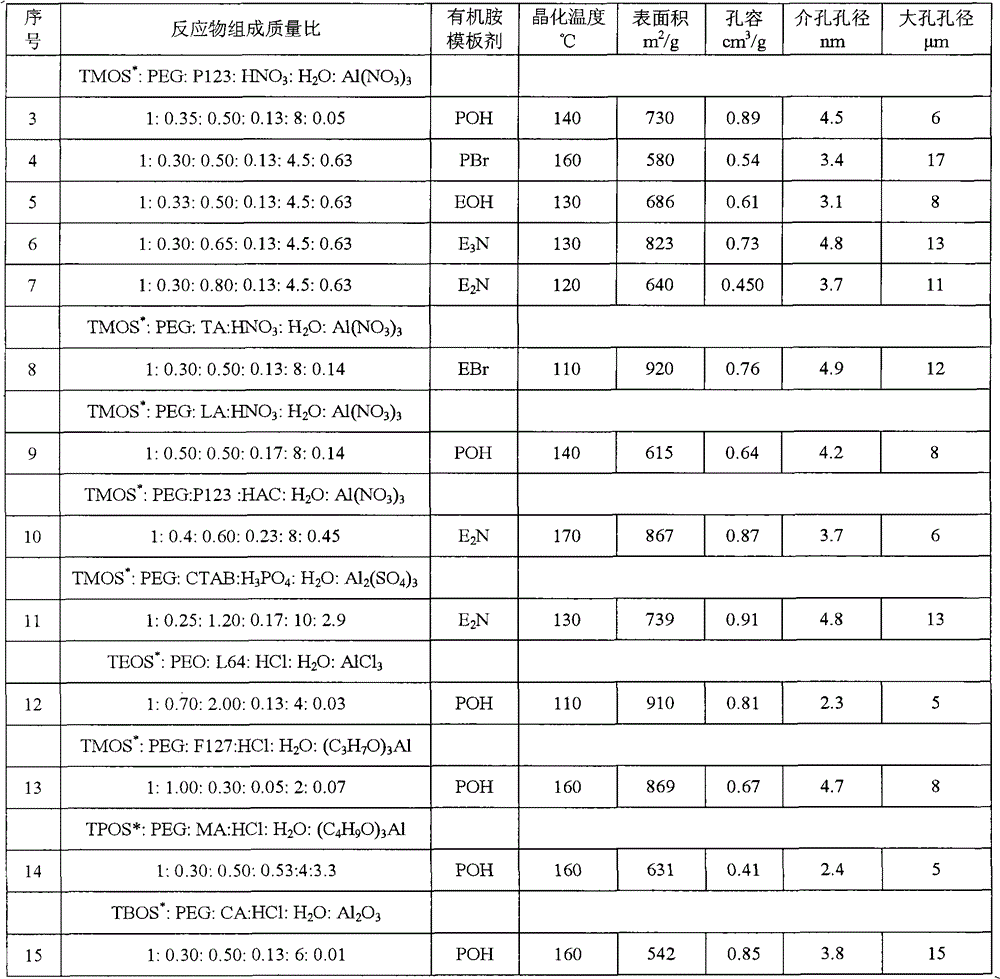

Embodiment 3~15

[0028] According to the various steps and conditions of [Example 1], the silicon-aluminum oxide material is obtained, but the silicon source (tetramethyl orthosilicate TMOS, tetraethyl orthosilicate TEOS, tetrapropyl orthosilicate TPOS, orthosilicate) is changed. tetrabutyl silicate (TBOS), aluminum source (aluminum nitrate, aluminum sulfate, aluminum chloride, aluminum isopropoxide, aluminum isobutoxide and pseudoboehmite Al 2 o 3 ), the type of phase separation inducer R1 (polyethylene glycol PEG, polyoxyethylene PEO) or structure directing agent R2 (polyoxyethylene-polyoxypropylene-polyoxyethylene (molecular weight 12000, F127), polyoxyethylene-polyoxyethylene Oxypropylene-polyoxyethylene (molecular weight 2900, L64), cetyl trimethyl ammonium bromide CTAB, citric acid CA, lactic acid LA, tartaric acid TA, malic acid MA), organic amine template (tetrapropyl hydroxide Ammonium (POH), tetrapropylammonium bromide (PBr), tetraethylammonium hydroxide (EOH), tetraethylammonium br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com