Window material, preparing method and application thereof

A technology of window material and red mud, which is applied in the field of recycling industrial waste red mud, can solve the problems of poor fireproof performance, insufficient hardness, no use, etc., achieve good sound insulation and heat insulation performance, improve processing performance, and increase consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

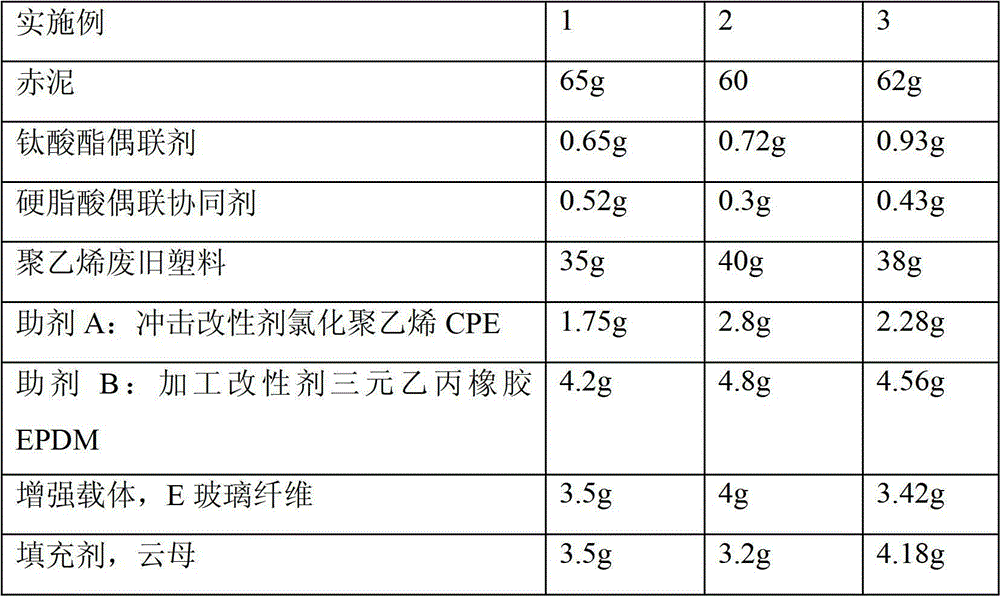

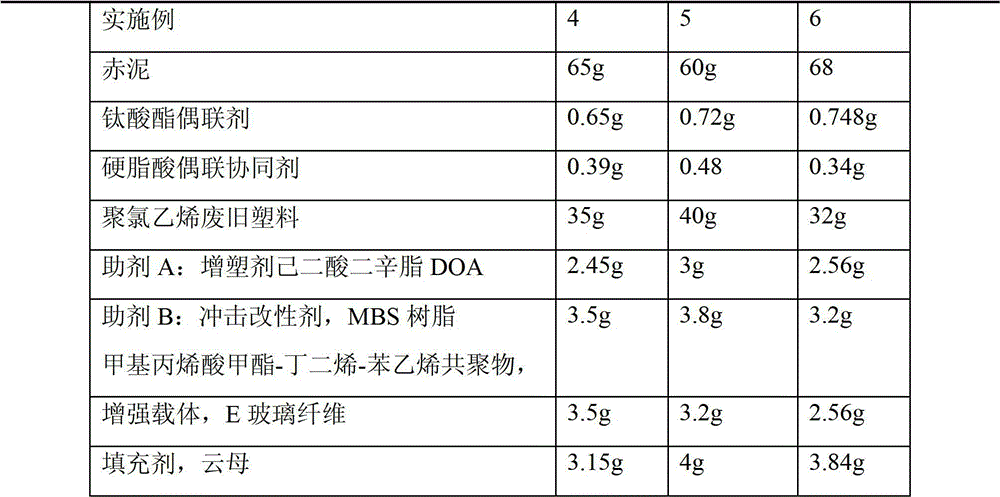

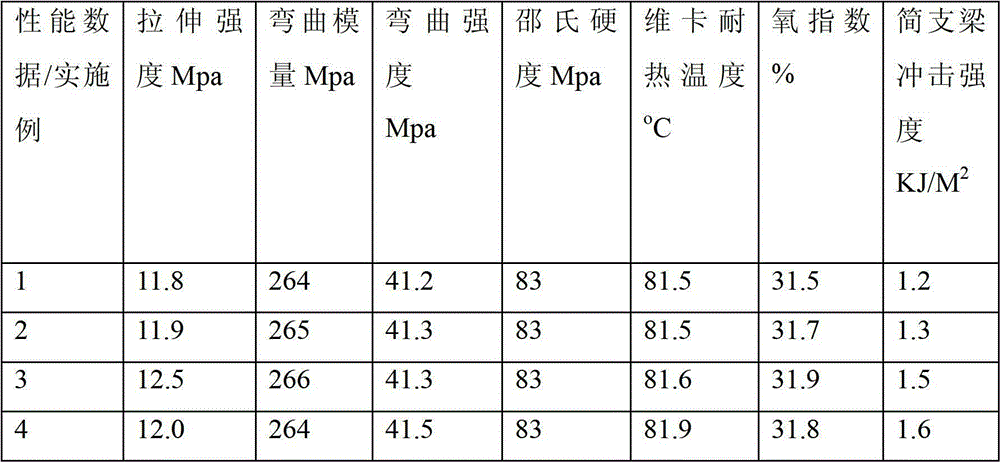

Embodiment 1

[0083] Embodiment 1. Preparation of window material 1

[0084] Step 1. Activate red mud:

[0085] (1) Dry 65g of red mud in a rotary flash dryer to make the water content less than 0.3%, and the particle size is greater than or equal to 150 mesh powder,

[0086] (2) Put the evaporated red mud into DYHL300 / 600 mixing and kneading machine, the speed is 1000 rpm, self-friction heat generation, when the temperature of the mixer rises to 100-110°C, remove the red mud The free moisture in the red mud should be controlled to be less than or equal to 0.3%, the general time is 2 to 5 minutes, and then add titanate coupling agent, the amount added is 1% to 1.2% of the red mud, 100 to 120°C In a mixer, surface activate the red mud and stir for 5-10 minutes. When the temperature drops to 50°C, add coupling synergist stearic acid in an amount of 0.5-0.8% of the amount of red mud, stir evenly at 48-52°C, and then discharge for use.

[0087] Step 2. Plastic and Additive Treatment:

[008...

Embodiment 2

[0104] Embodiment 2. step is the same as embodiment 1.

Embodiment 3

[0105] Embodiment 3. step is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com