Method and apparatus for adjusting ejection angle position of sub-nozzle in an air jet loom

A jet angle and air jet technology, applied in looms, textiles, papermaking, textiles, etc., can solve the problems of inability to make precise adjustments, and the inability to adjust the position of the nozzle jetting angle, achieve easy setting and operation, and reduce the process and time. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

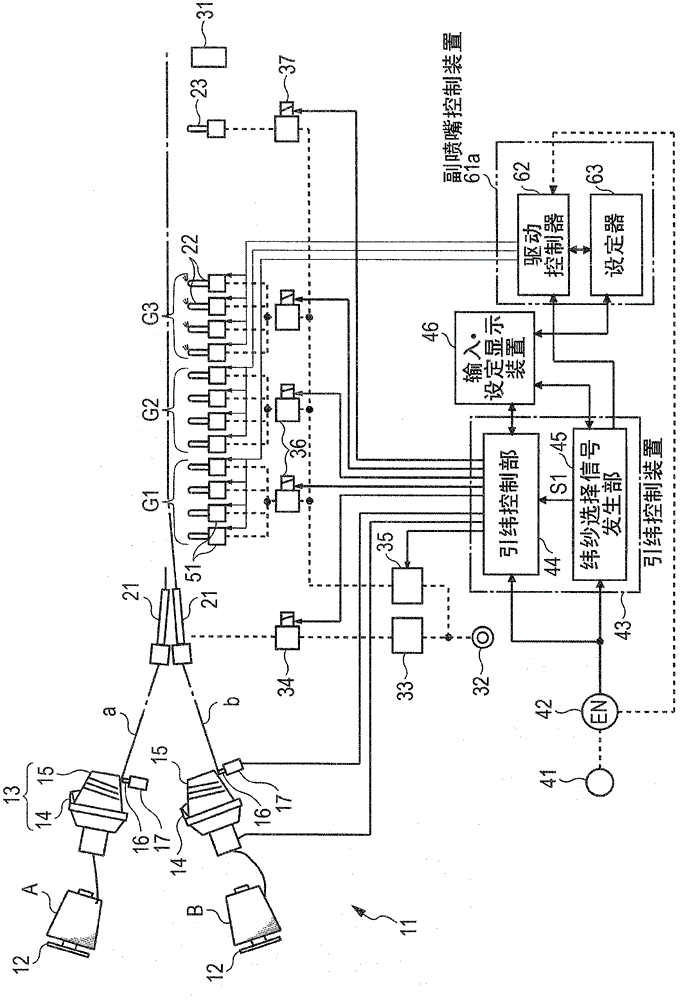

[0049] figure 1 As an example of an air jet loom to which the present invention is applied, main parts of a loom including a multi-color weft insertion device are shown. exist figure 1 In the figure, the two-color weft insertion device 11 that inserts two kinds of weft yarns (the weft yarn a wound on the yarn supply body A, and the weft yarn b wound on the yarn supply body B) is shown, and the two-color weft insertion device 11 corresponds to the multi-color weft insertion device of the present invention.

[0050] exist figure 1 In the weft insertion device 11, the weft yarn a and the weft yarn b are drawn from the yarn supply body A or B supported by each yarn supply body frame 12, and introduced into the yarn winding of the drum type length measuring weft storage device 13, for example. The inside of the arm 14 is wound around the outer peripheral surface of the drum 15 by the rotational movement of the yarn winding arm 14 while the outer peripheral surface of the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com