Hydraulic walking type percussion reverse circulation slot repairing machine

A walking and reverse circulation technology, which is applied to drilling equipment, drilling equipment and methods, and earthwork drilling and production, can solve problems such as single drilling, easy drilling deviation, and inability to penetrate the canal bottom, so as to improve work efficiency and double The effect of flat sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

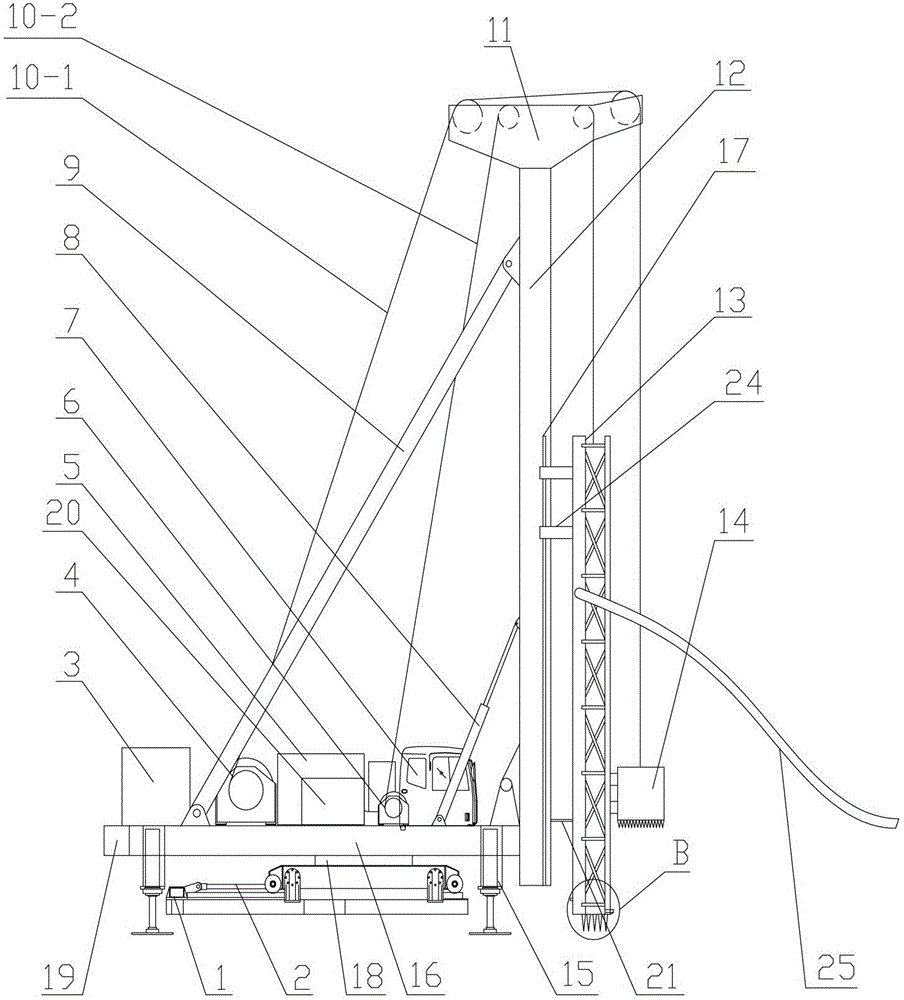

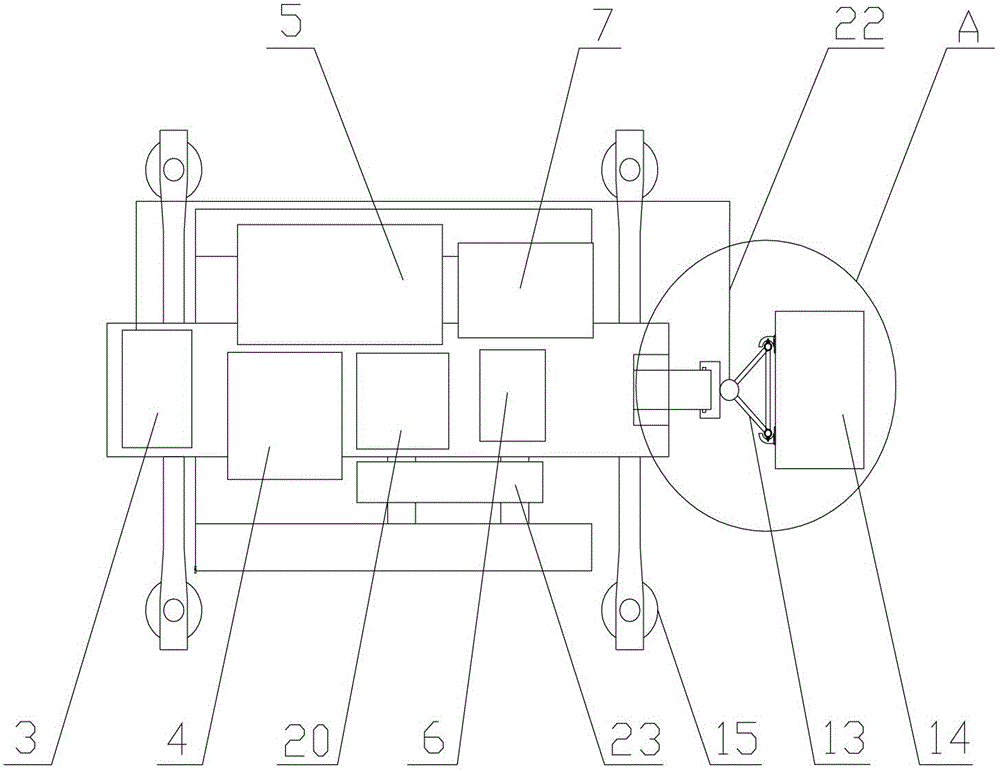

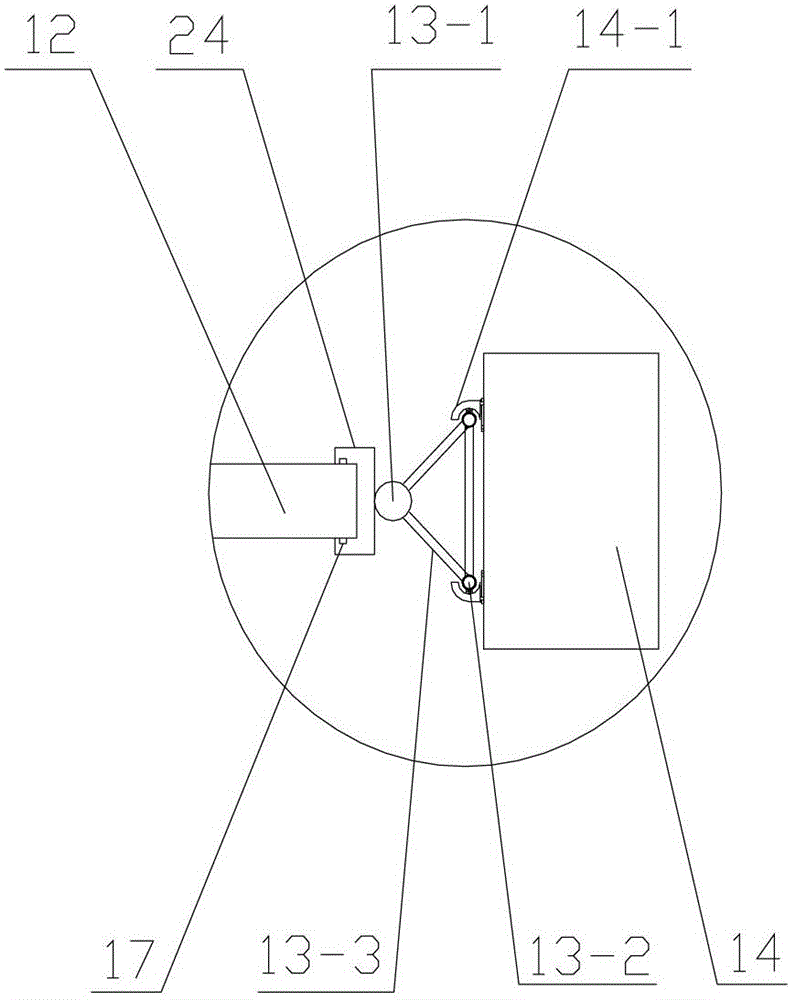

[0018] Such as figure 1 with figure 2 As shown, the hydraulic walking impact reverse circulation groove repairing machine includes chassis 1, walking cylinder 2, air compressor 3, main hoist 4, auxiliary hoist 6, cab 7, mast 12, outrigger 15, frame 16 and a hydraulic oil tank 19, the chassis 1 is arranged under the vehicle frame 16, the chassis 1 is connected with the vehicle frame 16 through a slewing support 18, and the four legs 15 are arranged on both sides of the front and rear ends of the vehicle frame 16 (with figure 1 The right side is the front, the same below), the air compressor 3, the main hoist 4, the generator set 5, the auxiliary hoist 6, the fuel tank 20 and the electrical cabinet 23 are all arranged on the vehicle frame 16, and the hydraulic oil tank 19 is arranged on the vehicle The rear end face of the frame 16; this hydraulic walking type impact rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com