Waterproof structure for shield-method tunnel anti-floating anchor rod node

A technology of anti-floating bolt and shield method, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as inability to be directly applicable, and achieve the effects of simple structure, meeting waterproof requirements, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

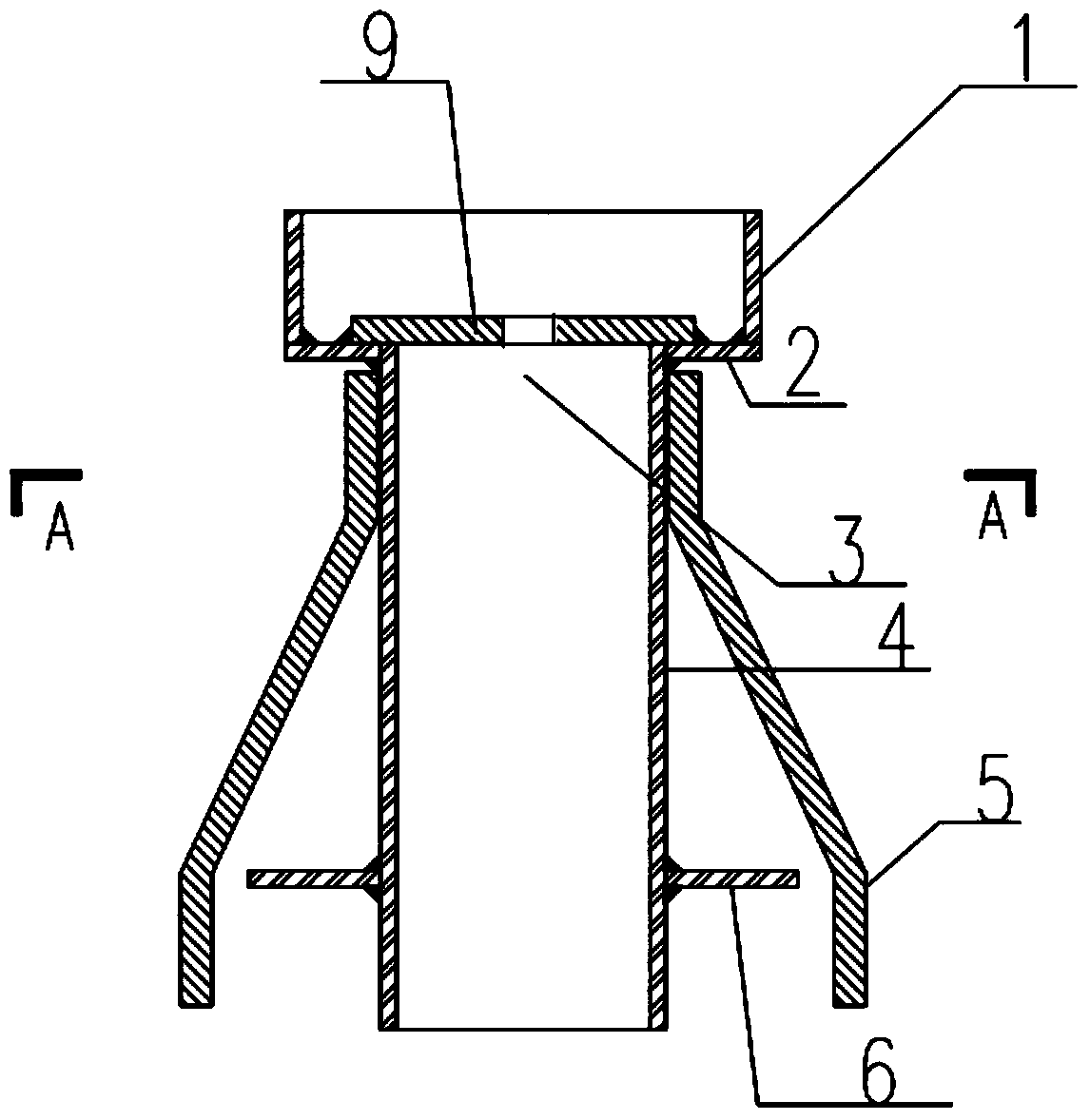

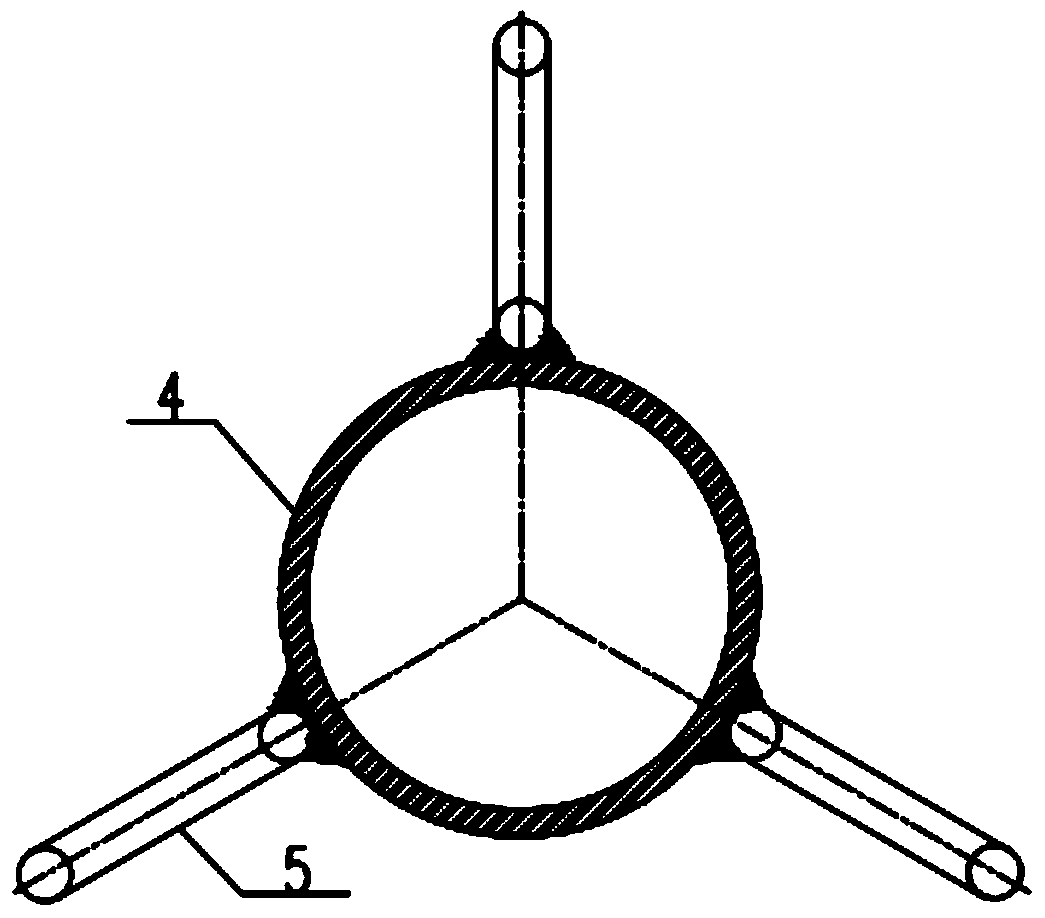

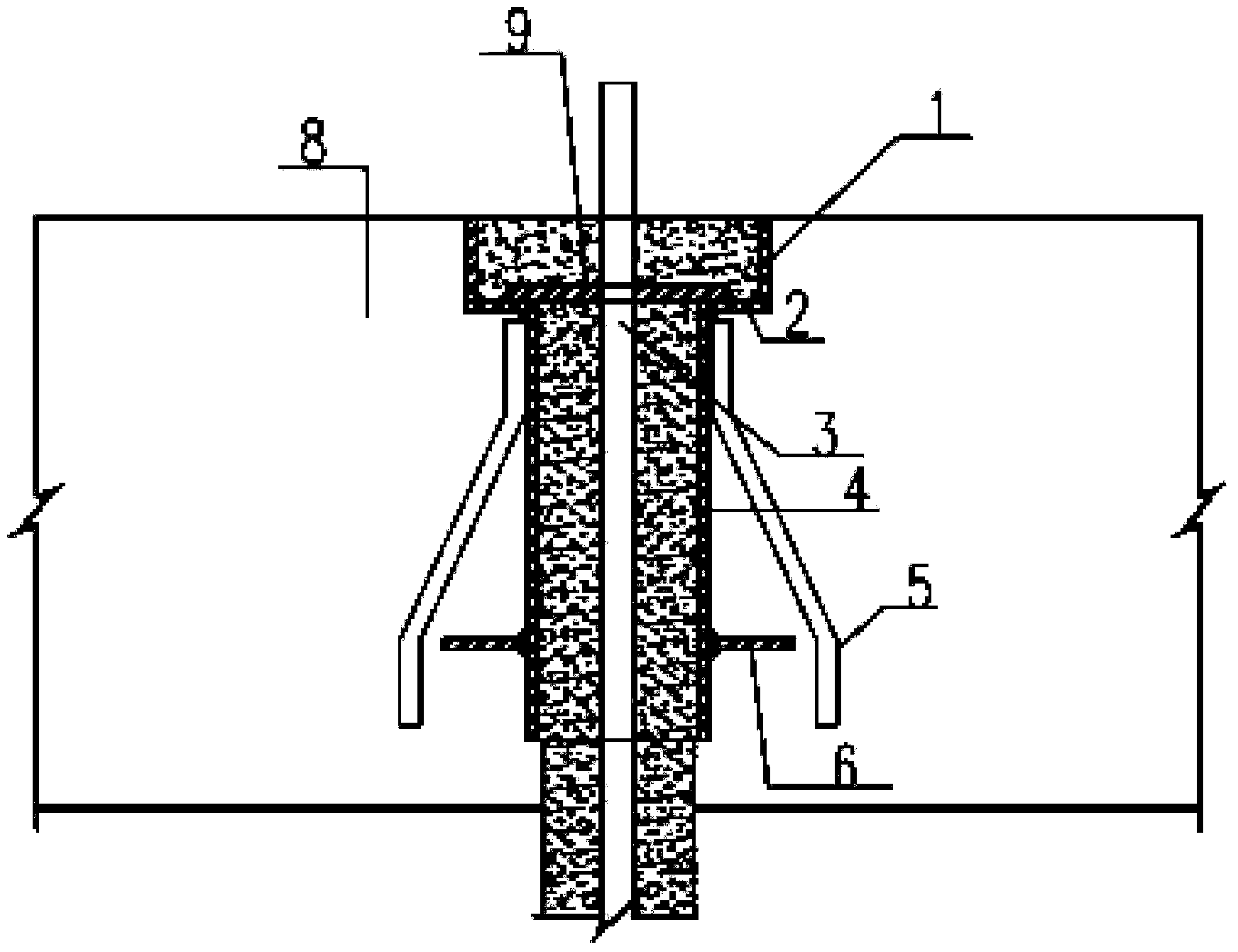

[0017] Such as figure 1 and figure 2 As shown, a specific embodiment of the waterproof structure of the anti-floating anchor rod node of the shield tunnel method of the present invention, the waterproof structure includes a steel pipe body with a built-in sealing end plate 9 and a water-stop steel ring 6 arranged on the outer side of the steel pipe body. Bolt holes are provided on the end plate 9 .

[0018] As a specific implementation of this embodiment, the above-mentioned steel pipe body includes a first steel pipe 4 and a second steel pipe 1 coaxially arranged, the diameter of the second steel pipe 1 is larger than the diameter of the first steel pipe 4, and one end of the second steel pipe 1 passes through the connecting steel pipe. One end of the ring 2 and the first steel pipe 4 is welded and fixed, and the sealing end plate 9 is welded and fixed on the connecting steel ring 2, wherein the preset anchor hole on the sealing end plate 9 can be welded and sealed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com