Seal-air automatic switching valve for flue damper door

A technology of sealing air and automatic switching, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of high cost, low operating cost and low cost of electric valves, and reduce the installation pipeline and auxiliary workload and cost. The effect of reducing and reducing the problem of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

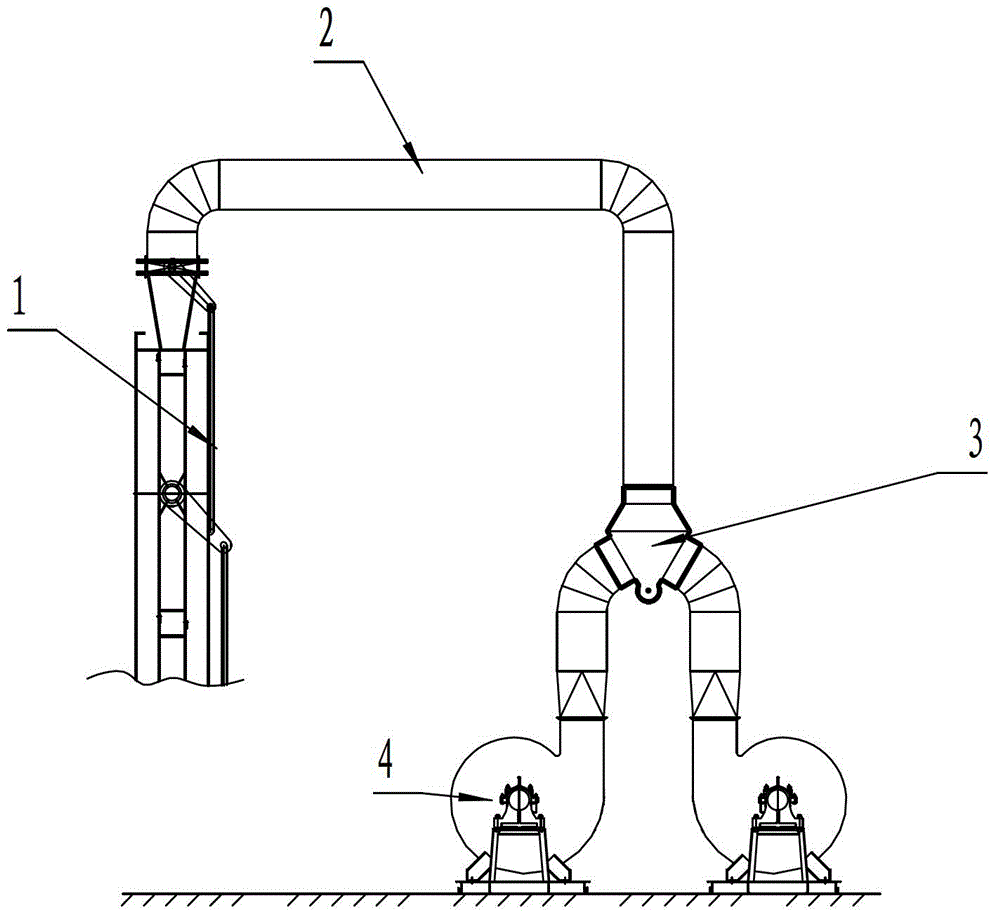

Embodiment 1

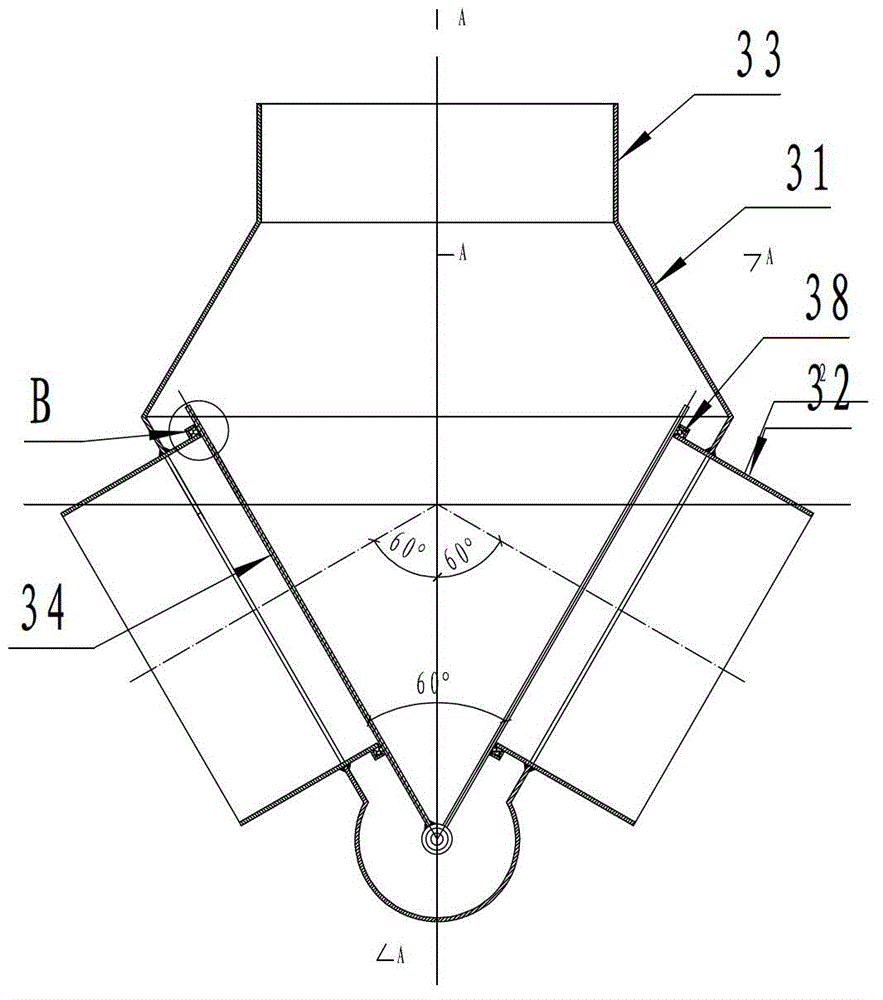

[0019] Embodiment 1, a sealed air automatic switching valve 3 for a smoke damper door 1, is characterized in that: the cylindrical switching valve housing 31 with a pentagonal cross-section is a top plate equipped with an outlet pipe 33, and the two bottom sides are respectively The tee that intake pipe 32 is housed, the angle between two bottom sides is 60 degrees, and the air intake pipe is perpendicular to the bottom side, and the junction of the two bottom sides is an arc connection, and a rotating shaft 37 is housed in the arc, and a shaft that can be wound around is housed on the rotating shaft. Rotating flat valve plate 34 . In the side that the air intake pipe front end stretches into, its periphery is equipped with polyurethane sealing ring 38.

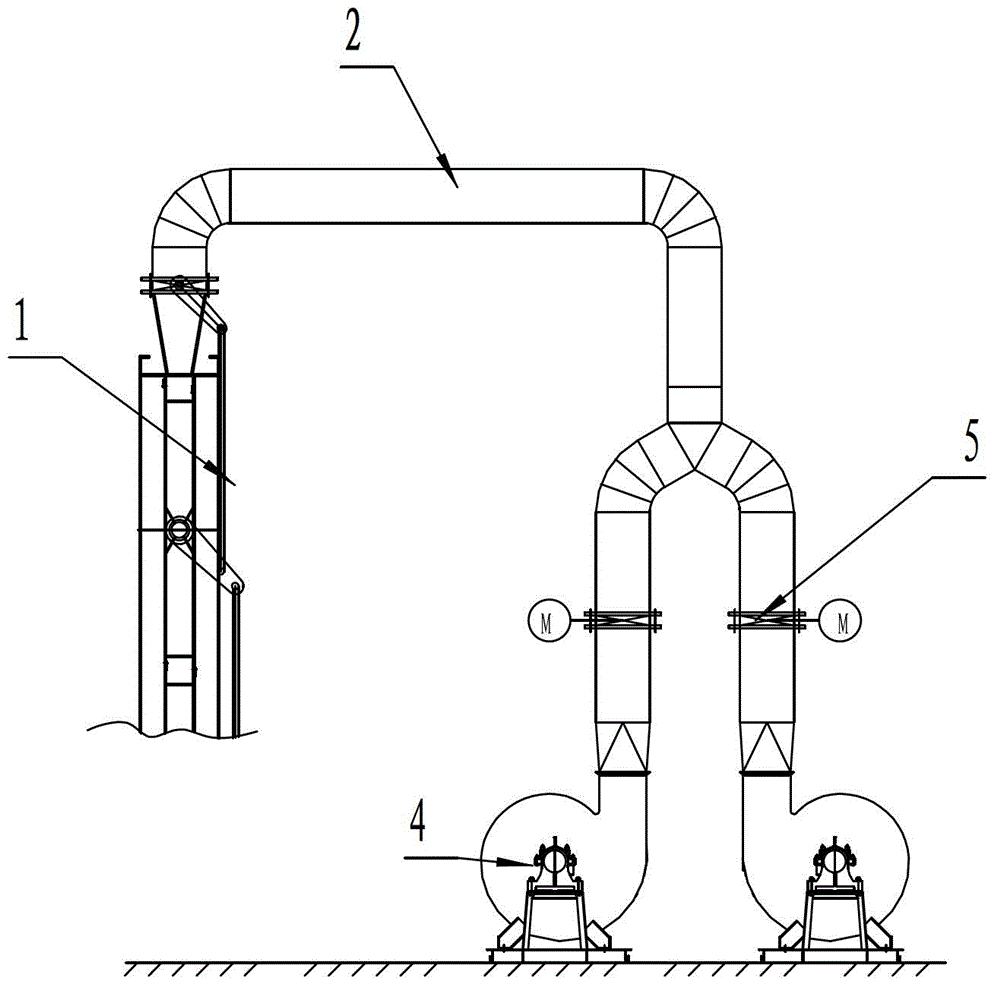

Embodiment 2

[0020] Embodiment 2, a sealed air automatic switching valve 3 for smoke damper door 1, characterized in that: a cylindrical switching valve housing 31 with a pentagonal cross section, and a flat plate on the top of the housing is equipped with a vertical air outlet pipe 33 , the two bottom sides are respectively equipped with the tee of the air intake pipe 32, the two bottom sides are at an angle of 60 degrees, the air intake pipe is perpendicular to the bottom side, and the joints of the two bottom sides are connected by an arc, and a rotating shaft 37 is housed in the arc, and the rotating shaft A flat valve plate 34 that can rotate around an axis is mounted on it.

[0021] The inner length of the bottom side of the housing where the front end of the air intake pipe extends into is 50 mm, and a polyurethane sealing ring 38 with a height of 5 mm is installed on the outer periphery of the air intake pipe mouth. The polyurethane sealing ring is composed of a steel frame 381 wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com