Railway switch gap offset detection method based on image processing

An image processing and offset technology, applied in image data processing, image analysis, measuring devices, etc., can solve the problems of not being able to find hidden dangers in the quality of equipment in time, unsatisfactory use effects, and unintuitiveness, so as to achieve intuitiveness and accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

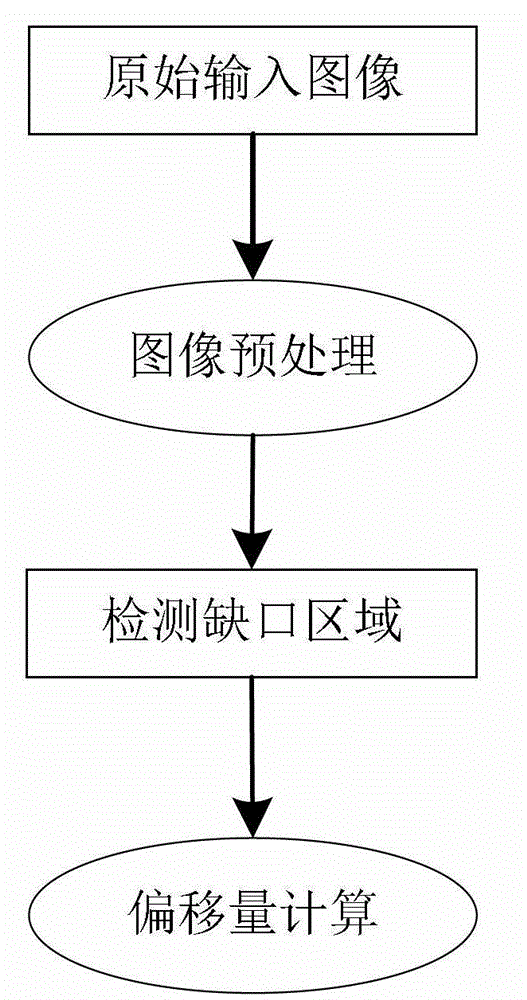

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

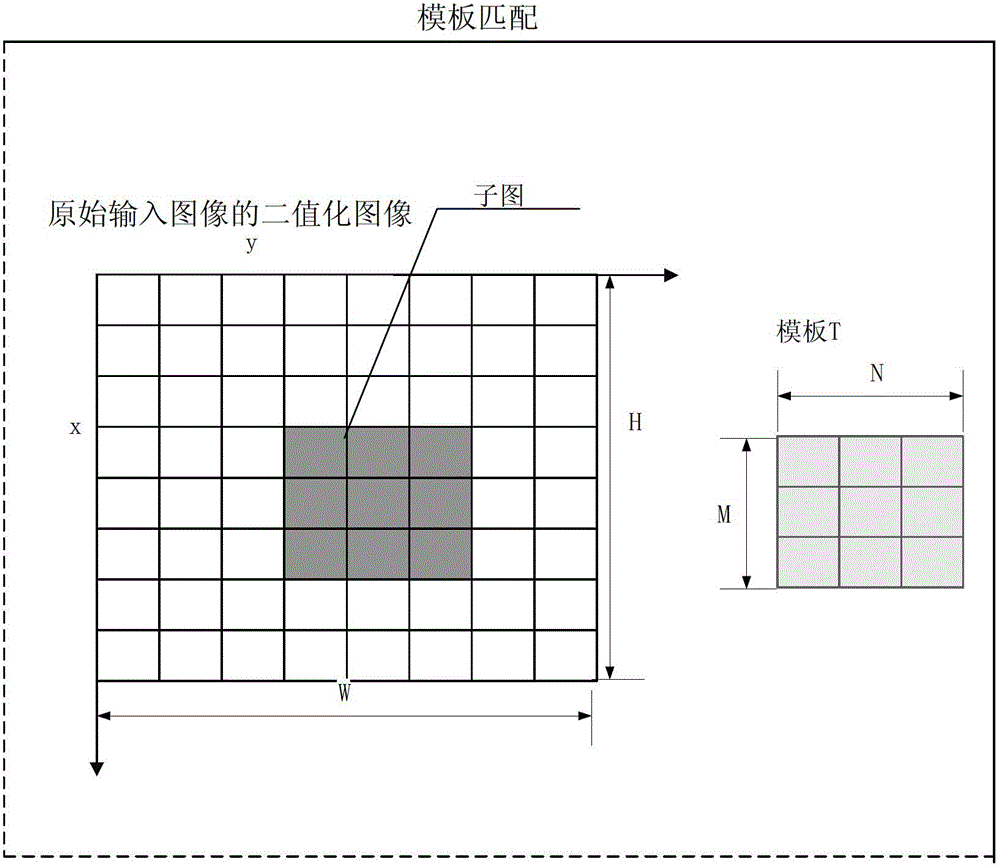

[0030] Such as figure 1 As shown, the specific implementation of the image processing-based railway turnout offset detection method can be divided into several major steps: original input image, image preprocessing, detection of gap area, and offset calculation.

[0031] S11, image preprocessing

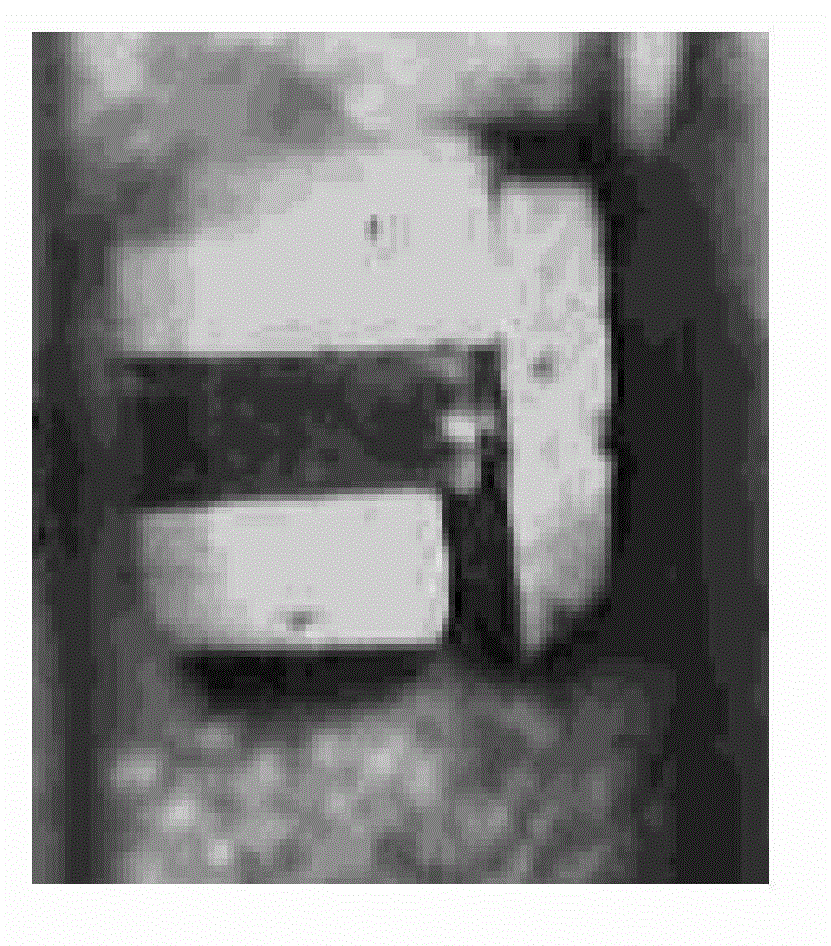

[0032] This step is to perform image preprocessing on the original input image to obtain a binary image of the original input image. The original input image refers to the image obtained by real-time acquisition of the image of the gap region of the switch rod through the micro digital image sensor installed in the gap region of the switch rod by the railway switch conversion monitoring system, such as figure 2 shown.

[0033] Image preprocessing includes the following steps:

[0034] S211, converting the RGB color mode of the original image into the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com