Blind zone optimized progressive eye lens and mold thereof

A technology for ophthalmic lenses and blind areas, which is applied in glasses/goggles, optics, instruments, etc., can solve problems such as the position and size of astigmatism in blind areas that are not explained, and achieve improved fusion effects, improved comfort, and reduced deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Consider a lens with a freeform surface facing object-space space and a spherical or cylindrical surface facing the wearer of the spectacle, the outer progressive ophthalmic lens. A lens suitable for the right eye is considered here, and a lens suitable for the left eye can be obtained by simply taking the mirror image of the lens of the right eye. The processing surface is the outer surface of the lens, which is a convex free-form surface with a power and a cylinder at each point, and the diameter of the lens is 72mm.

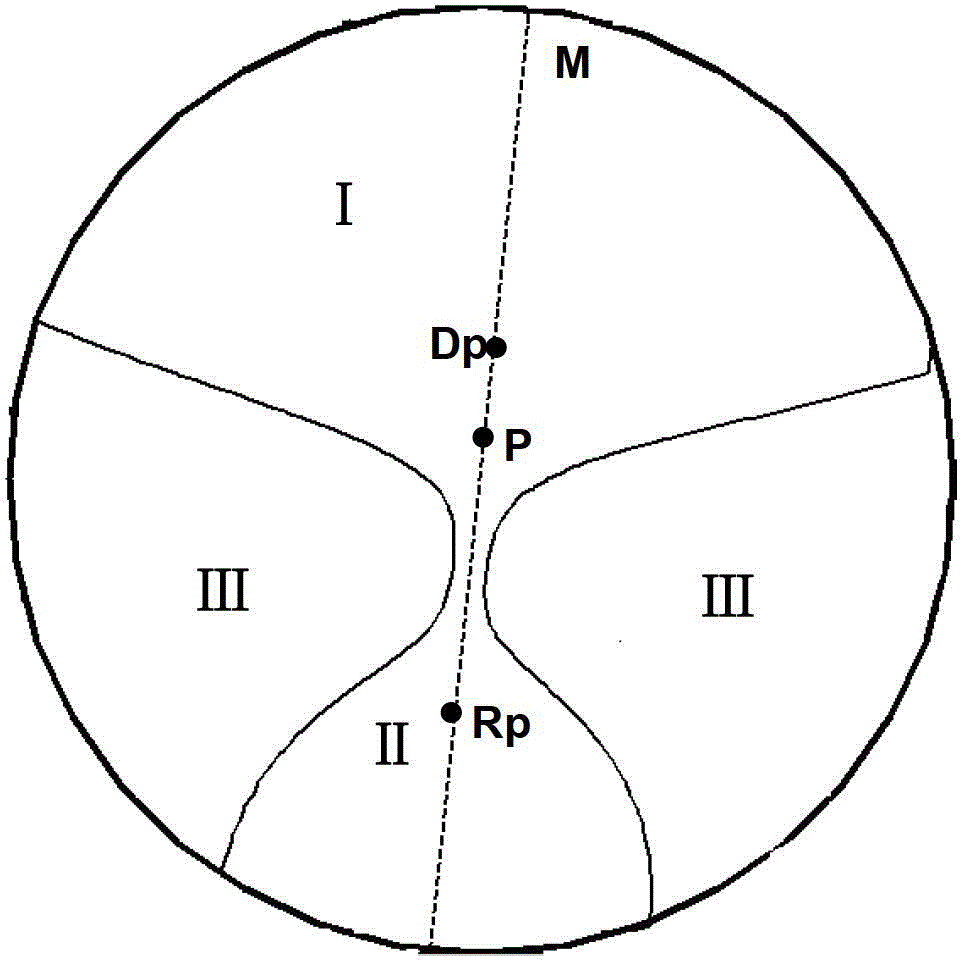

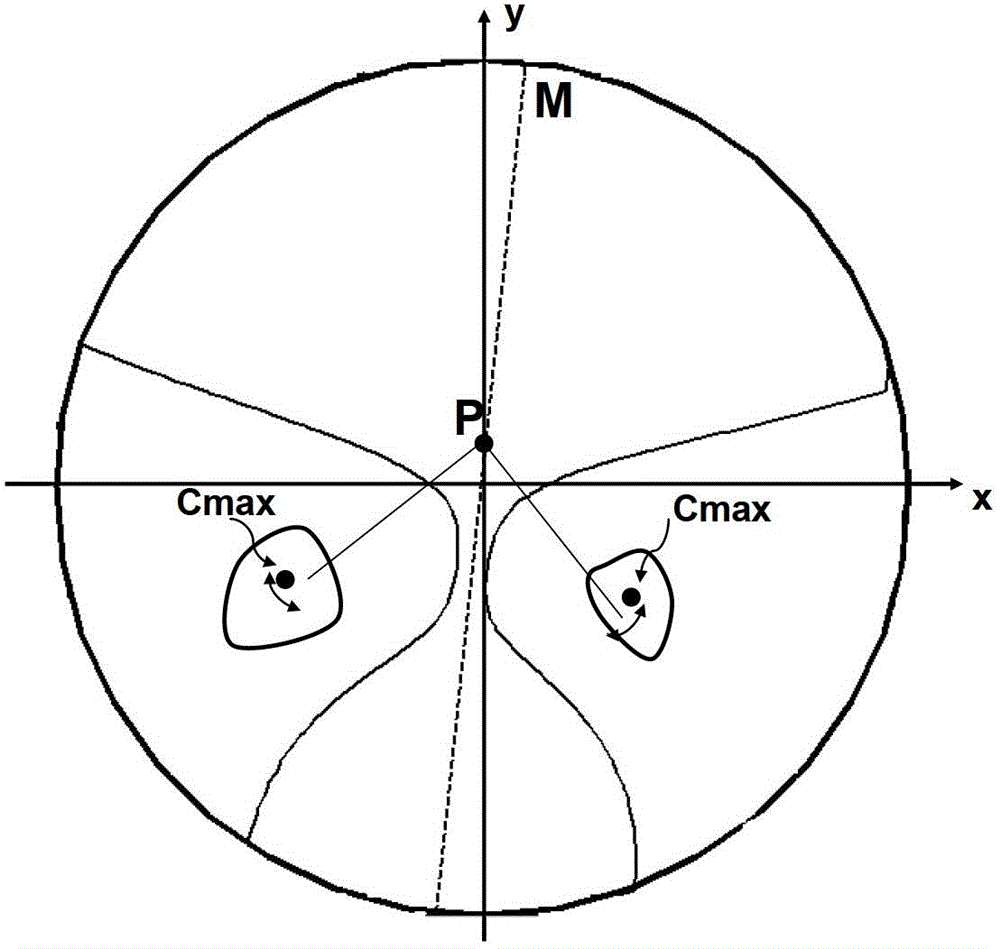

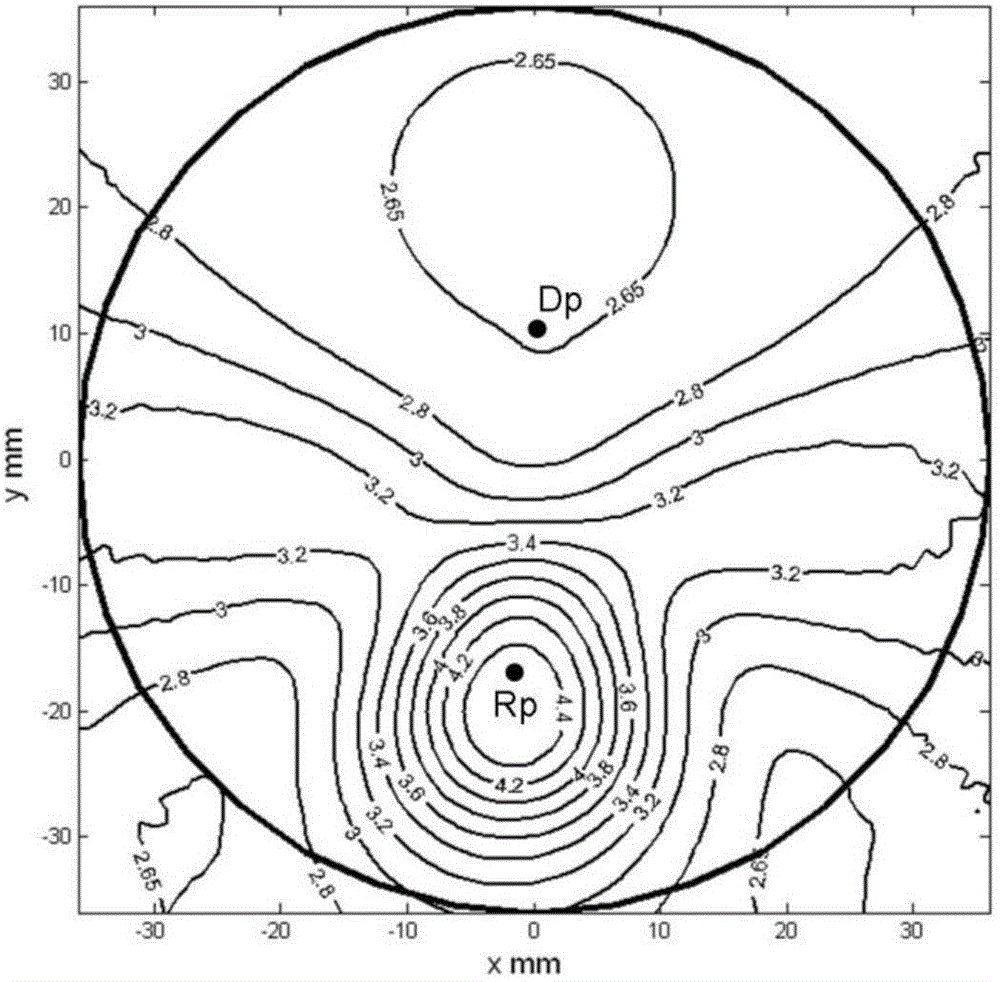

[0039] image 3It shows the isofocal power contour map of this surface, which is precisely the projection of the power distribution of the freeform surface on the outer surface of the lens on the plane. exist image 3 The upper part of the lens has a broad focal power stabilization zone called the far zone. As a reference point, the far point Dp is in the far zone. The focal power value of the far point is 2.65D. image 3 The lower part of the lens ...

Embodiment 2

[0044] The biggest difference from Embodiment 1 is that the lens in this example has a spherical or cylindrical surface facing the object space and a free-form surface facing the wearer of the glasses, that is, the inner progressive ophthalmic lens. The machined surface is the inner surface of the lens, which is a concave, free-form surface with one power and one cylinder at each point. The power of a lens is made up of the powers of the inner and outer sides. Specifically, the optical power of the lens is approximately equal to the optical power of the outer surface minus the optical power of the inner surface. A progressive lens with addition, if its free-form surface is designed on the inner surface of the lens, its addition will be negative. That is to say, the focal power of the free-form surface in this example has the feature of light reduction from top to bottom.

[0045] For this example consider a lens suitable for the left eye with a lens diameter of 70 mm. As me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Optical power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com