Two-dimensional ultrasonic area array probe and manufacturing method thereof

An ultrasonic and area array technology, applied in the fields of ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, organ movement/change detection, etc., can solve the problems of low preparation efficiency, complex process, ultrasonic There are too many connecting wires for area array probes, etc., to save time and cost, reduce process difficulty, improve preparation efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

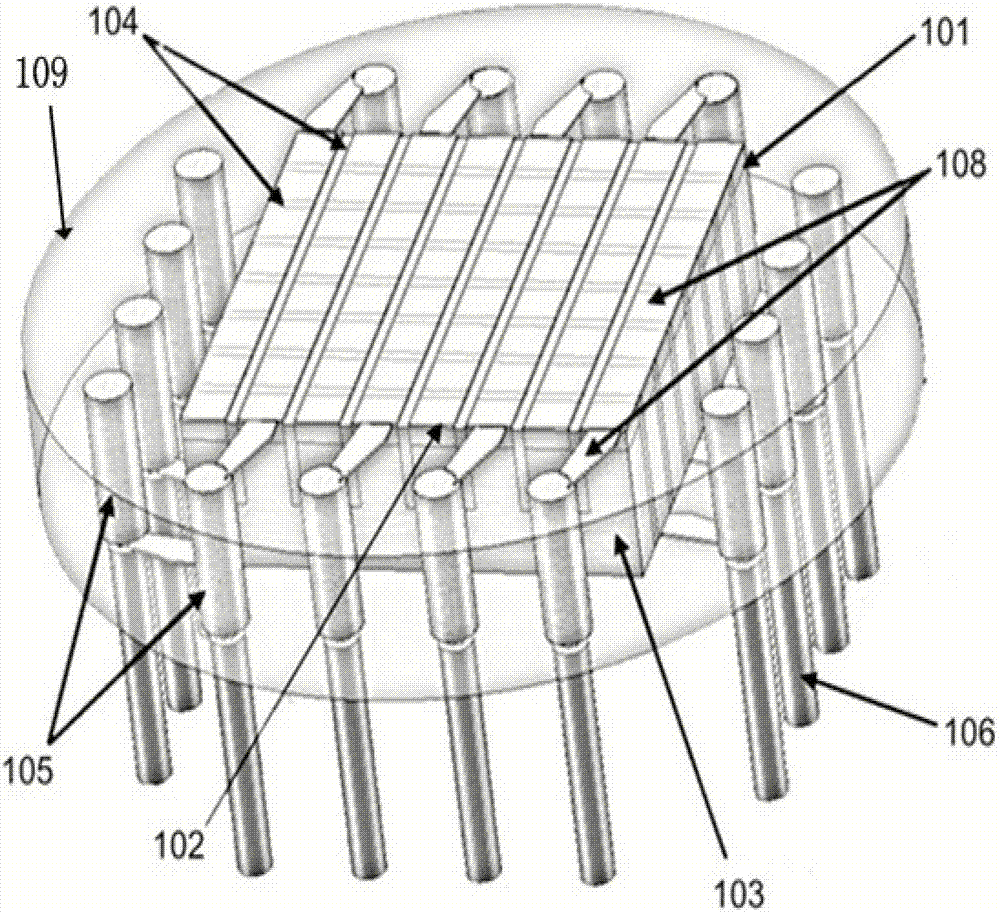

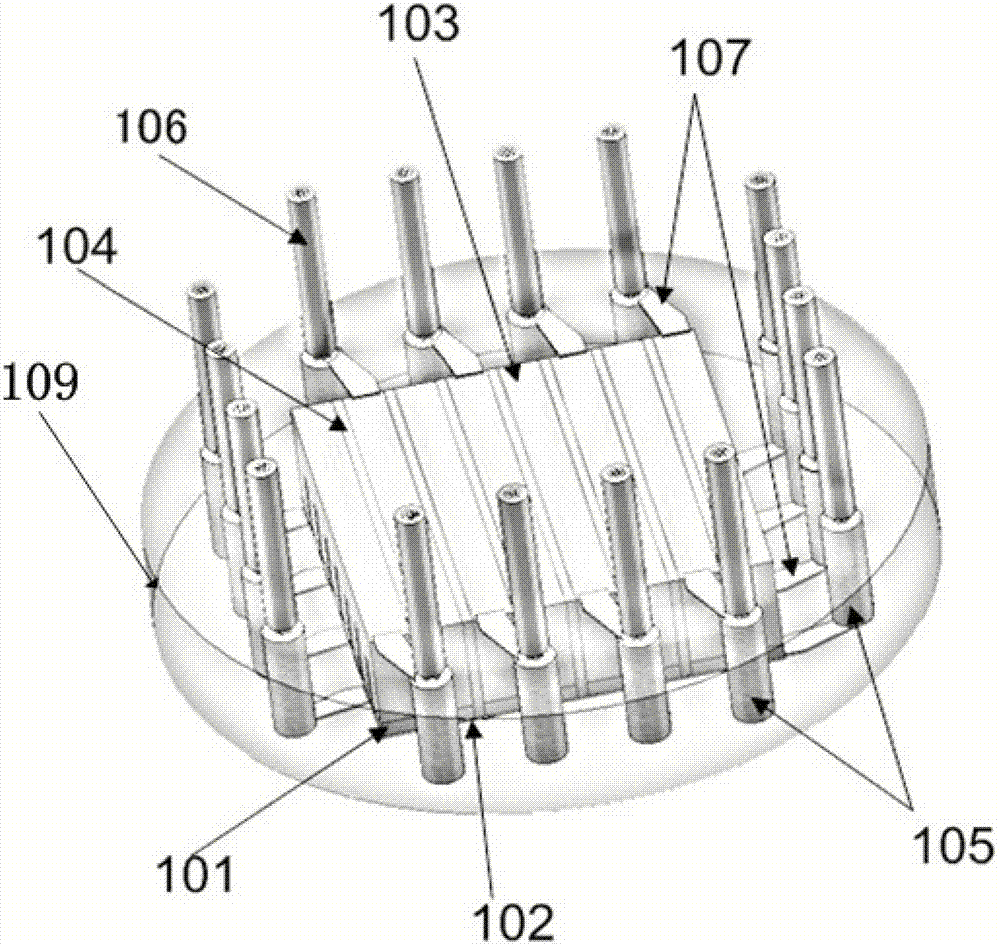

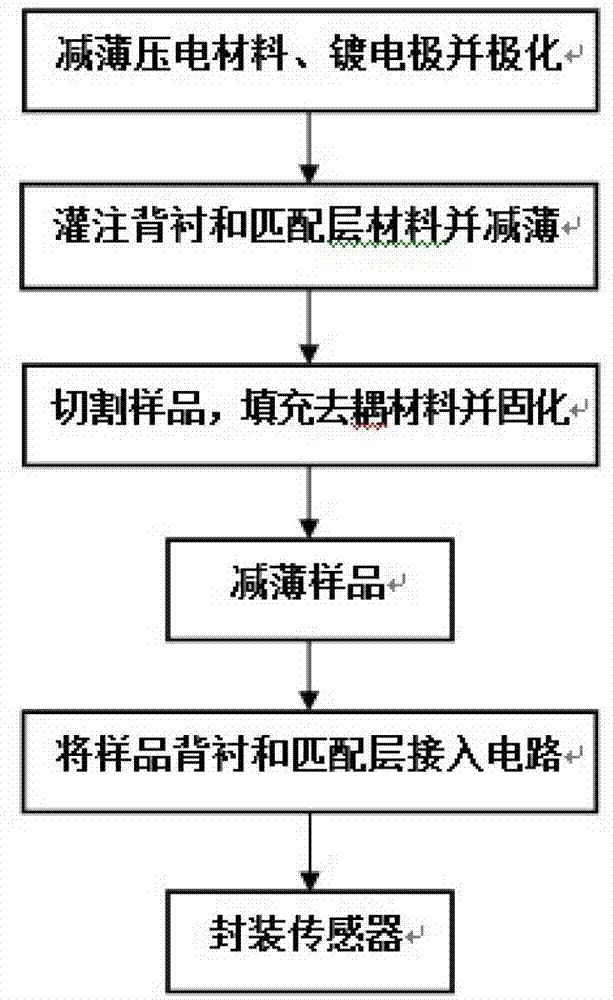

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The present invention takes a two-dimensional N×N area array as an example, where N is the number of array elements in the length direction or width direction of the area array, and specifically describes the preparation method of the ultrasonic area array probe, but the array in the present invention The type of element arrangement is not limited to this square array structure, and it is also applicable to use array elements with different lengths for the length and width of the array. The number of array elements in the length direction or width direction of the planar array can also be specifically selected according to needs. In addition, the array structure of the present invention may also be in the form of a circle, an ellipse or other shapes.

[0023] Such as figure 1 , the two-dimensional ultrasonic surface array probe in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com