Manual sliding system for armrests of auxiliary fascia consoles

A technology of sliding system and sub-instrument panel, applied in passenger space and other directions, can solve the problems of high cost, complex structure, and many assembly processes of metal slide rails, and achieve the effect of simple and practical structure, reduction of manufacturing cost, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

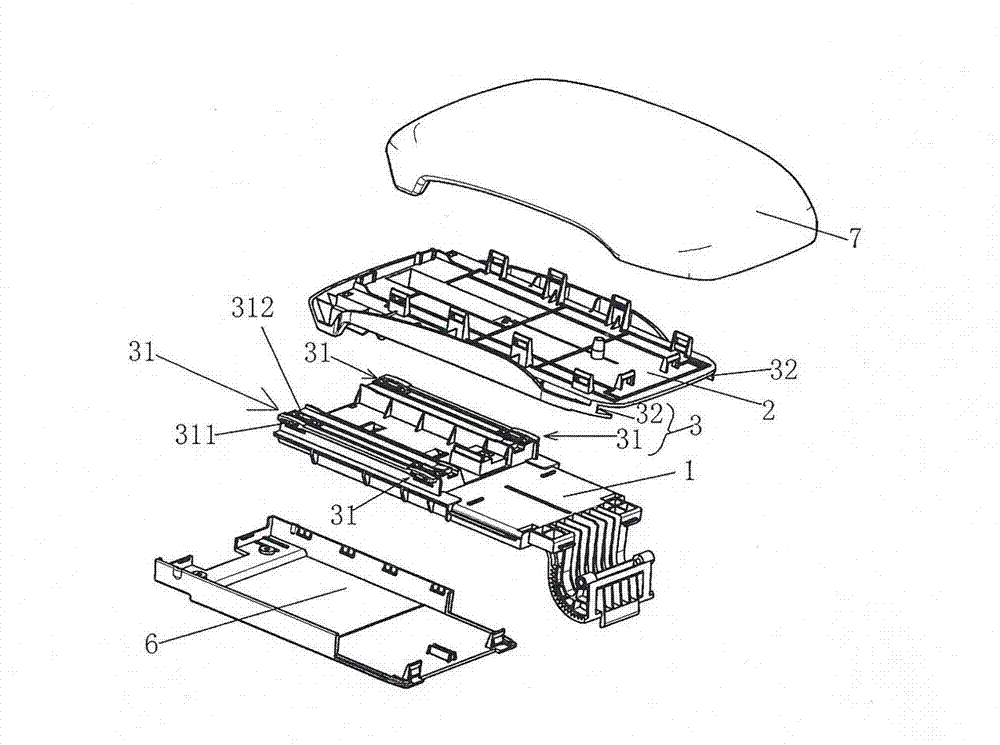

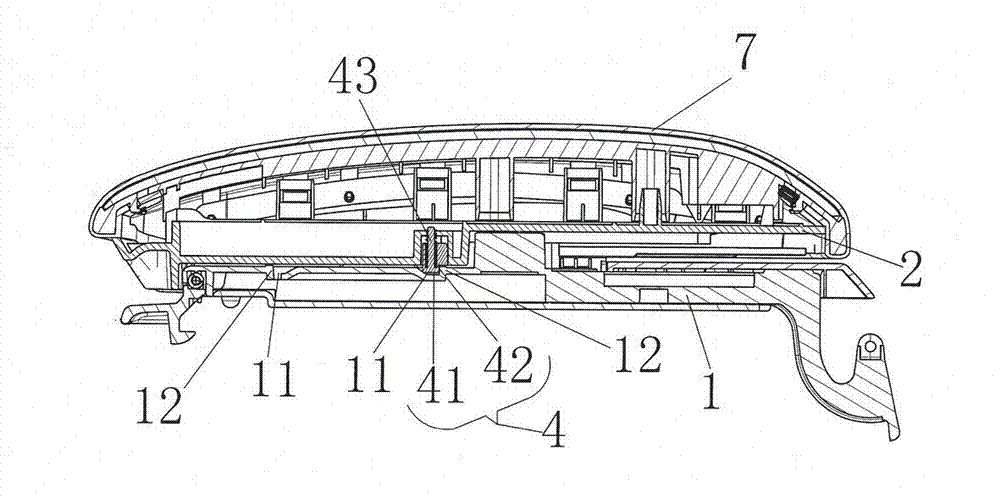

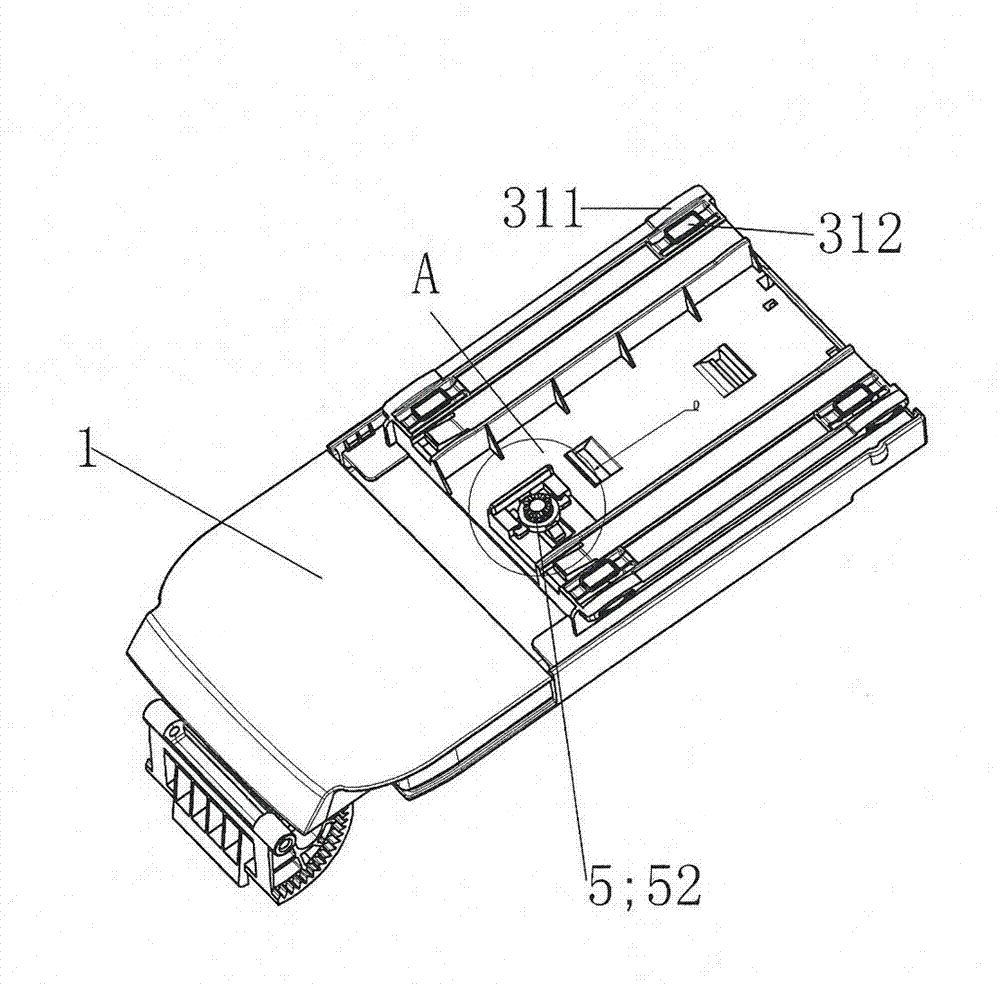

[0014] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment is composed of a lower frame 1, an upper frame 2, a sliding mechanism 3, a locking mechanism 4, a damper 5, a lower cover 6 and an outer cover 7, and the lower cover 6, the lower frame 1, and the outer cover 7 from the bottom Combined together, the sliding mechanism 3, the locking mechanism 4 and the damper 5 are located between the lower frame 1 and the upper frame 2; the sliding mechanism 3 is formed by the slide rail 31 formed on the lower frame 1 and the upper frame 2. 32, the slide rail 31 is composed of a rigid structure 311 and an elastic structure 312, the rigid structure 311 provides bearing capacity, the elastic structure 312 ensures smooth sliding and stability, the slide rail 31 is located in the chute 32, and the elastic structure 312 of the slide rail 31 The surface is pasted with lubricating material; the locking mechanism 4 is composed of a locking pin 41 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com