Working solution pre-heating device

A technology of preheating device and working fluid, applied in inorganic chemistry, non-metallic elements, chemical instruments and methods, etc., can solve problems such as energy consumption and increase production cost, and achieve the effect of reducing production cost and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

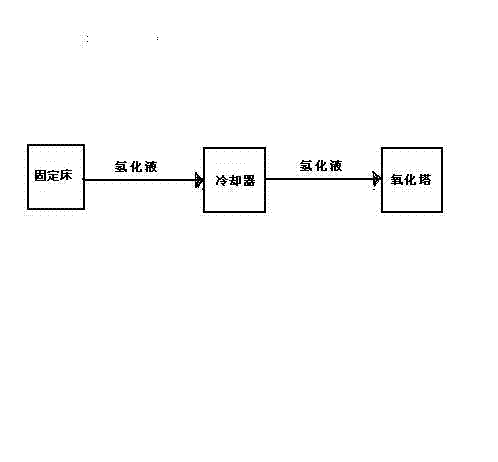

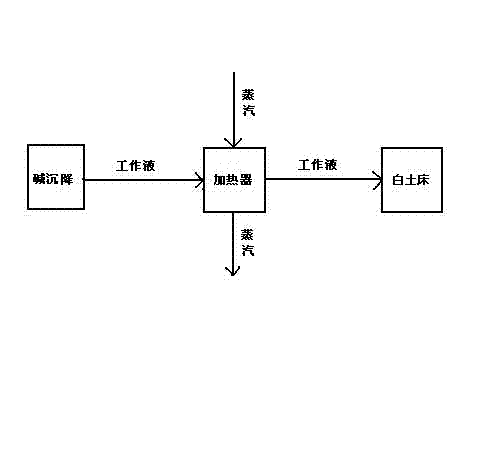

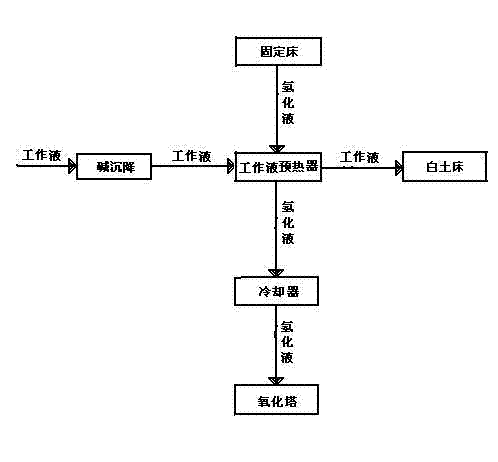

[0008] Combining the working fluid heating device and hydrogenation liquid cooling device into one, sharing a working fluid preheater and removing the steam heater, such as image 3 shown. Input the 65-degree high-temperature hydrogenated liquid into the working fluid preheater, heat the working liquid to 55 degrees, and meet the 55-degree temperature requirement for the working liquid to enter the clay bed; at this time, the hydrogenated liquid is also reduced from 65 degrees to 55 degrees After being further cooled to 45 degrees by the cooler, it enters the oxidation tower to react with air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com