A light hydrocarbon/diesel fuel reforming system and reforming method

A reforming system and diesel technology, applied in the charging system, adding non-fuel substances to fuel, combustion air/combustion-air treatment, etc., can solve the problems of waste of energy resources, high exhaust temperature of diesel engine exhaust, etc., to reduce pollution , reduce the volume, reduce the effect of combustion cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

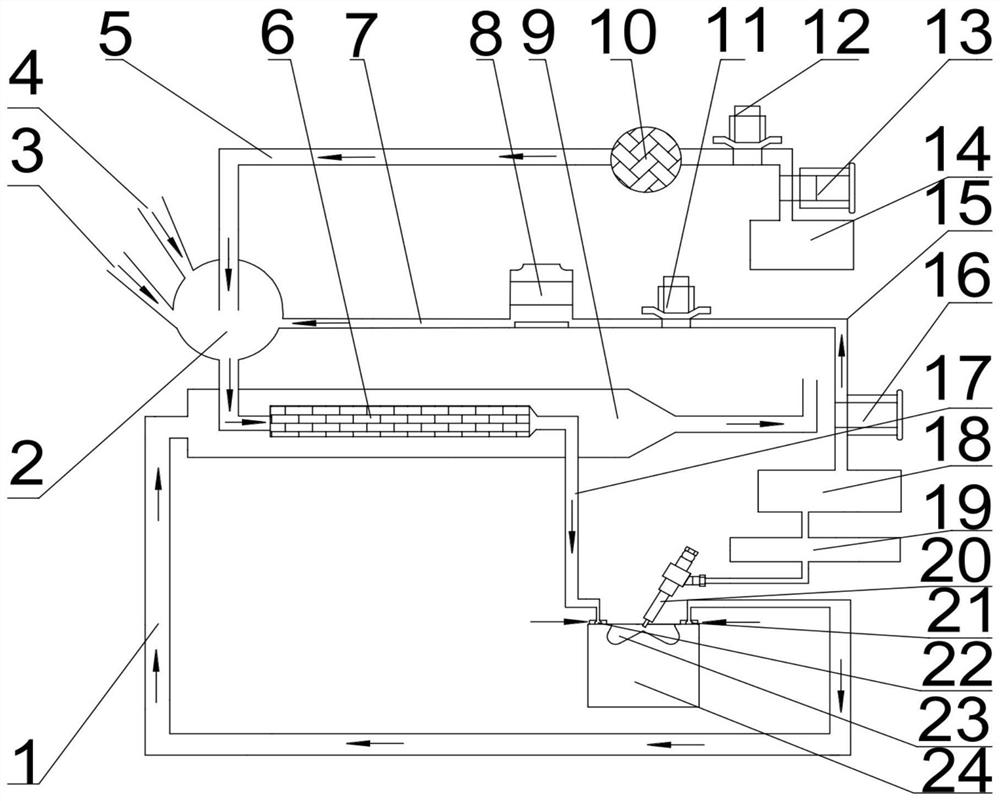

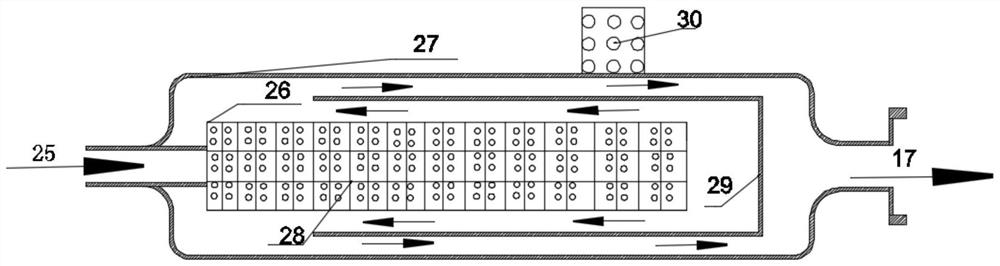

[0028] Such as figure 1 As shown, the light hydrocarbon fuel reforming system of the present invention includes a light hydrocarbon fuel supply device, a diesel fuel supply device, a reforming reaction device 6 and a gas mixer 2 . The gas mixer 2 is arranged after the light hydrocarbon fuel supply device, the reforming reaction device 6 is arranged after the gas mixer 2, the diesel fuel supply device is arranged in the diesel engine 15, and the exhaust gas 1 of the diesel engine is discharged into the exhaust gas from the exhaust valve 21. The pipe 9 is heated by the reforming reaction device 6 and discharged into the atmosphere. The temperature of the engine exhaust gas will be different under different working conditions. Therefore, a temperature compensator 30 is installed inside the reforming reaction device 6 to meet the reaction conditions temperature, so that the reforming reaction occurs normally.

[0029] Light hydrocarbon fuel supply device comprises light hydrocarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com