Precious metal methanation catalyst prepared by solution combustion method, preparation method and application

A methanation catalyst and solution combustion technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of small pore size and small specific surface area of methanation catalysts and other problems, to achieve the effect of improving catalytic performance, large specific surface area and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

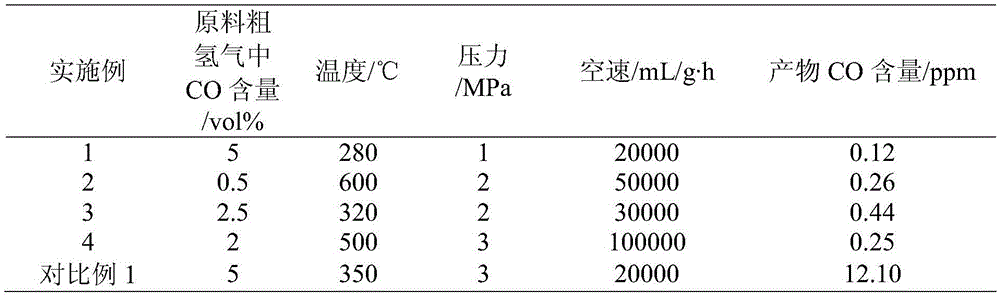

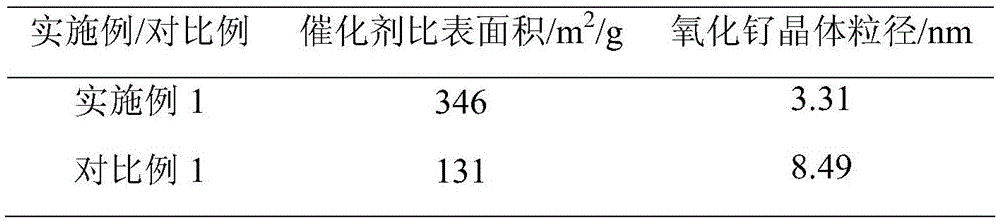

Embodiment 1

[0028] Weigh 1.2g of ruthenium nitrate, 69.9g of aluminum nitrate and 15g of urea, fully dissolve in 120mL of water, pour the solution into a ceramic evaporating dish, ignite under the conditions of microwave radiation wavelength 15cm, power 70W / mL solution, and collect the remaining powder after combustion , Grinding and granulating to 50-70 mesh to obtain a methanation catalyst. The catalyst composition is: RuO 2 5wt.%, Al 2 o 3 95wt.%. Put a certain mass of the above-mentioned catalyst into a 250mL fixed-bed reactor for reduction, the reduction condition is 450°C, and the volume composition is 15%H 2 with 85%N 2 , the space velocity is 3000mL / (g·h) and reduced for 6h. The reduced catalyst is used for fixed-bed methanation reaction, and the specific reaction conditions and results are shown in Attached Table 1.

Embodiment 2

[0030] Weigh 0.5g of rhodium nitrate, 18.6g of zirconium oxynitrate, 5g of ethylene glycol and 5g of polyethylene glycol-2000 and fully dissolve them in 45mL of water, pour the solution into a ceramic evaporating dish, microwave radiation wavelength 12cm, power 50W / mL solution conditions Ignite under the pressure, collect the remaining powder after combustion, grind and granulate to 60-80 mesh to obtain the methanation catalyst. The catalyst consists of: Rh 2 o 3 2wt.%, ZrO 2 98wt.%. Put a certain mass of the above catalyst into a 250mL fixed-bed reactor for reduction, the reduction condition is 650°C, and the volume composition is 10%H 2 with 90%N 2 , the space velocity is 5000mL / (g·h) and reduced for 2h. The reduced catalyst is used for fixed-bed methanation reaction, and the specific reaction conditions and results are shown in Attached Table 1.

Embodiment 3

[0032] Weigh 0.6g of palladium nitrate, 24.5g of cerium nitrate, 7g of glycine, and 3g of polyethylene glycol-1000 in 35mL of water to fully dissolve, pour the solution into a ceramic evaporating dish, microwave radiation with a wavelength of 17cm, and ignite under the conditions of a power of 40W / mL solution , collect the remaining powder after combustion, grind and granulate to 50-70 mesh to obtain the methanation catalyst. The catalyst composition is: PdO3wt.%, CeO 2 97wt.%. Put a certain mass of the above catalyst into a 250mL fixed-bed reactor for reduction, the reduction condition is 400°C, and the volume composition is 5%H 2 with 95%N 2 , the space velocity was 10000mL / (g·h) and reduced for 5h. The reduced catalyst is used for fixed-bed methanation reaction, and the specific reaction conditions and results are shown in Attached Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com