Method for preparing nitrogen-rich porous carbon material

A porous carbon and nitrogen-enriched technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of nitrogen-rich porous carbon materials such as no patents and literature reports, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Place the tetrasodium salt of ethylenediaminetetraacetic acid in the center of a tube-type resistance furnace, pass through high-purity argon gas protection, heat to 700 ° C, keep the temperature constant for 5 hours, and take it out after the furnace temperature cools to room temperature. Add excess dilute hydrochloric acid to remove metal oxides. Then wash with deionized water until neutral to obtain a nitrogen-rich porous carbon material.

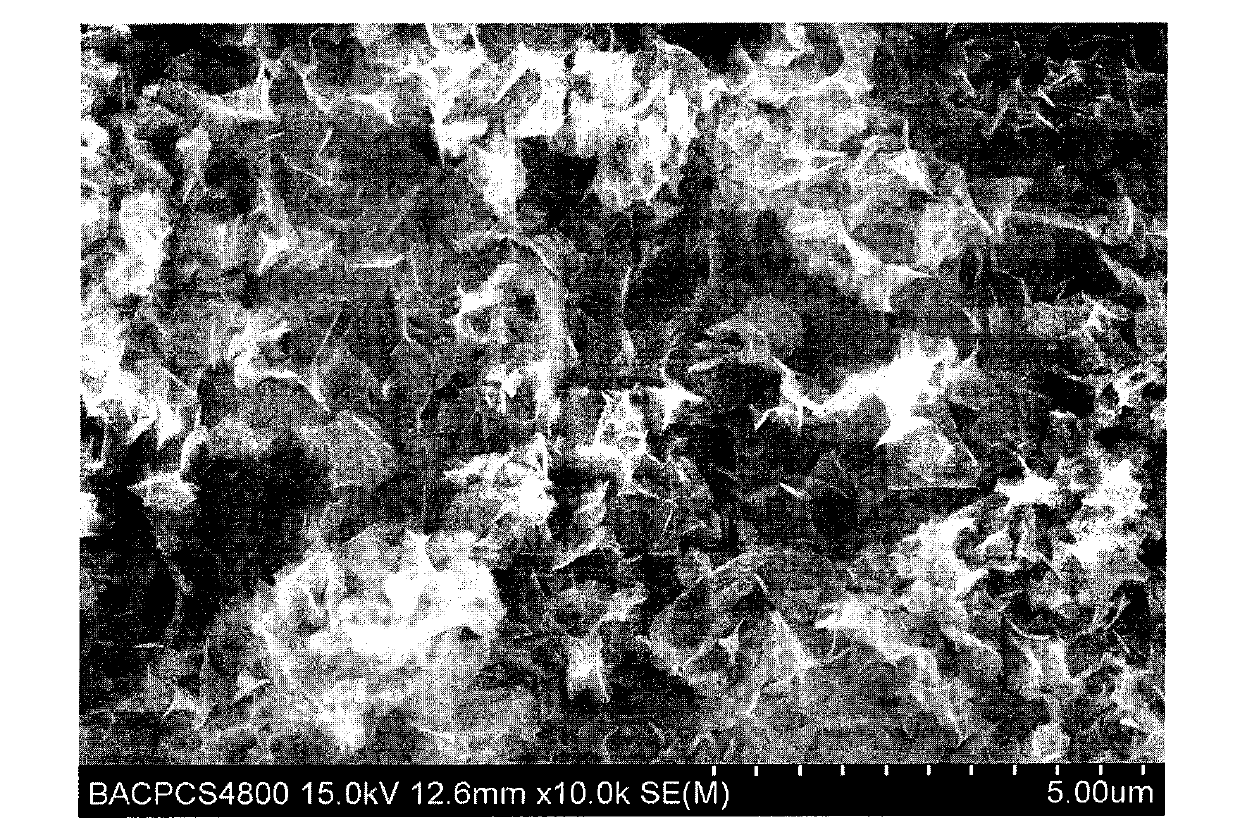

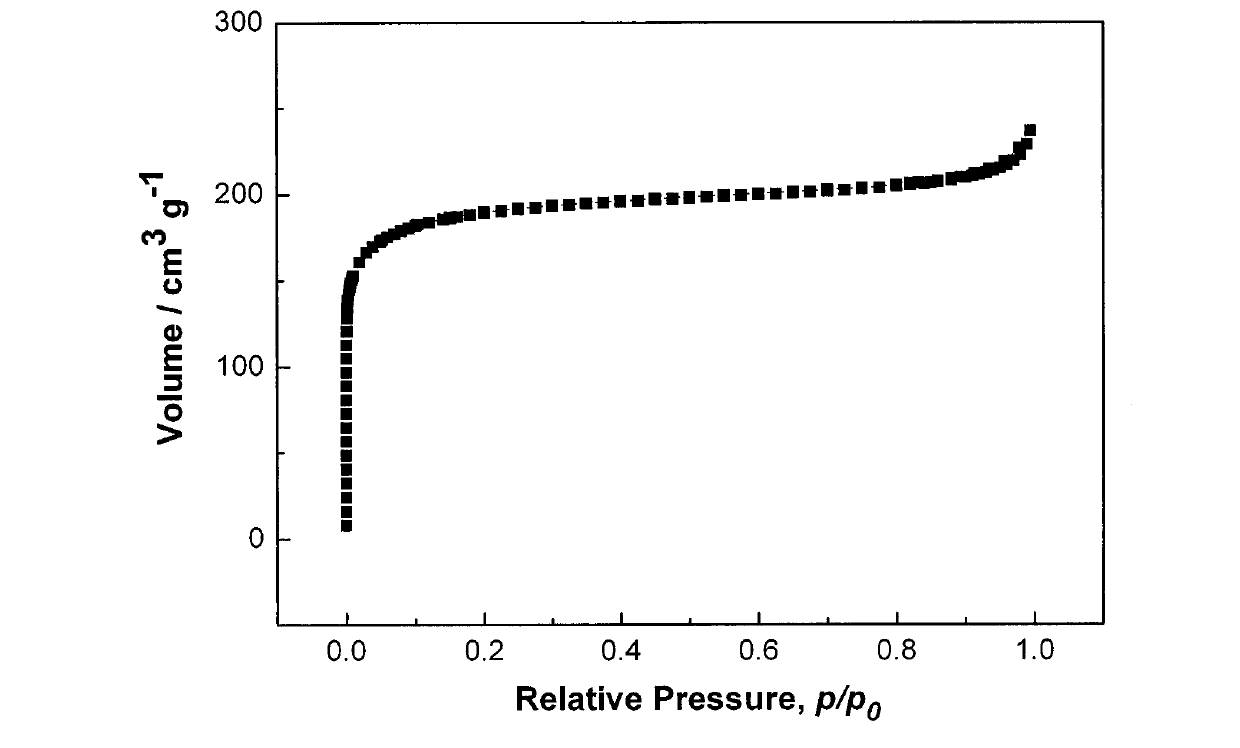

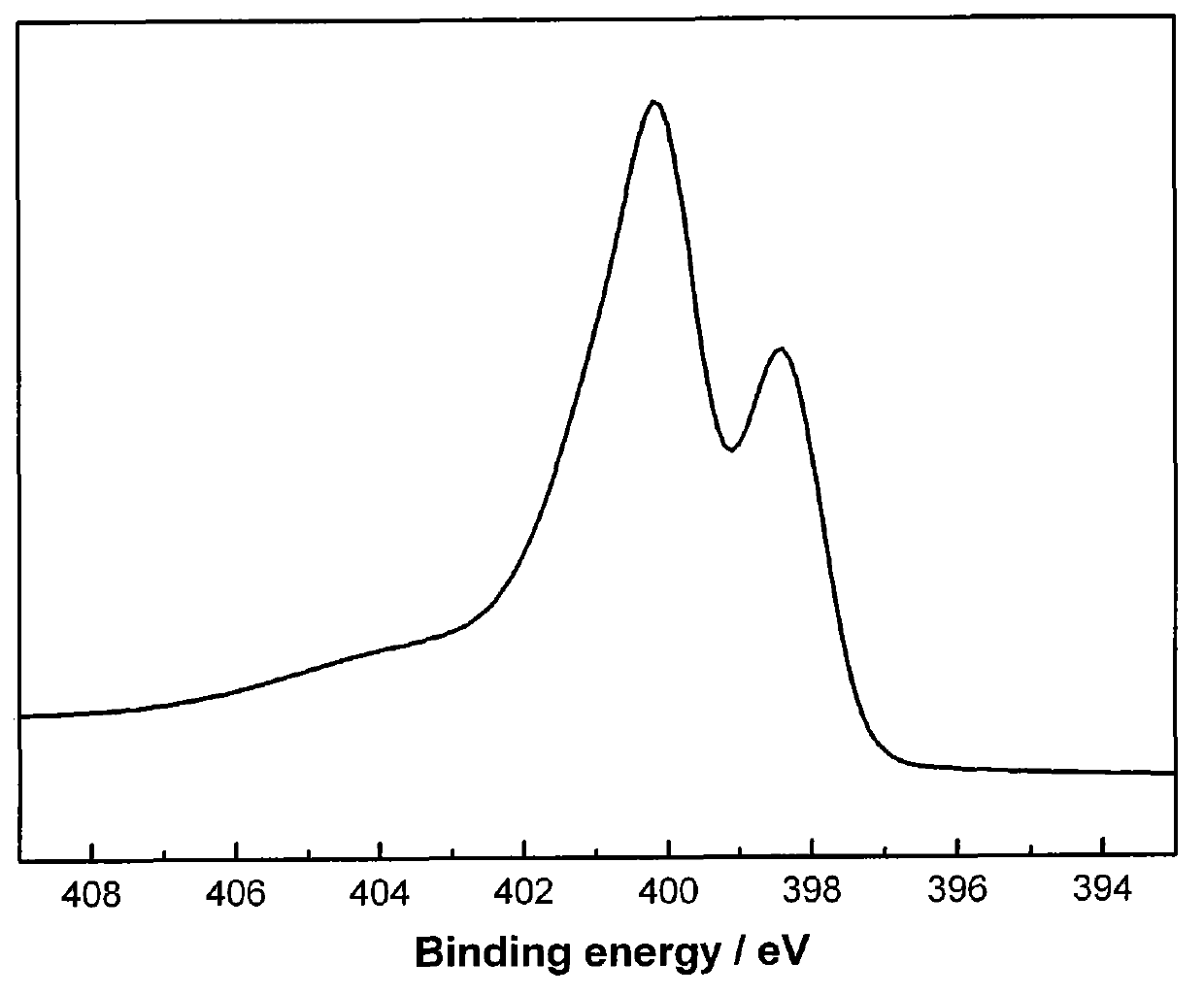

[0023] figure 1 It is the scanning electron micrograph of the obtained carbon material. Depend on figure 2 The nitrogen adsorption isotherm of the obtained carbon material shown in the calculation shows that its BET specific surface area is 708m 2 / g, pore volume 0.366cm 3 / g. Depend on image 3 X-ray photoelectron spectroscopy of the resulting carbon material shown gives a nitrogen content of 7.74%. The material is used in supercapacitors by Figure 4 The charge-discharge curve of the obtained carbon material at a curren...

Embodiment 2

[0025] Place disodium magnesium EDTA in a muffle furnace protected by high-purity nitrogen, heat to 800°C, keep the temperature constant for 2 hours, and take it out after the furnace cools down to room temperature. Add excess dilute sulfuric acid to remove metal oxides. Then wash with deionized water until neutral to obtain a nitrogen-rich porous carbon material. The BET specific surface area of the carbon material is 1811m 2 / g, pore volume 1.02cm 3 / g, the nitrogen content is 3.81%.

Embodiment 3

[0027] Place calcium ethylenediaminetetraacetate in a tubular resistance furnace, pass through high-purity nitrogen protection, heat to 900°C, keep the temperature constant for 1h, and take it out after the furnace cools down to room temperature. Add excess dilute hydrochloric acid to remove metal oxides. Then wash with deionized water until neutral to obtain a nitrogen-rich porous carbon material. The BET specific surface area of the carbon material is 1350m 2 / g, pore volume 1.61cm 3 / g, the nitrogen content is 2.32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com