Steel wire sealing type smokeless pickling line

A kind of pickling unit and closed technology, which is applied in the field of steel wire closed smokeless pickling unit, can solve the problems of easy jumping of steel wire and poor wiping effect, so as to reduce the amount of waste acid water, good cleaning effect, and reduce acid consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

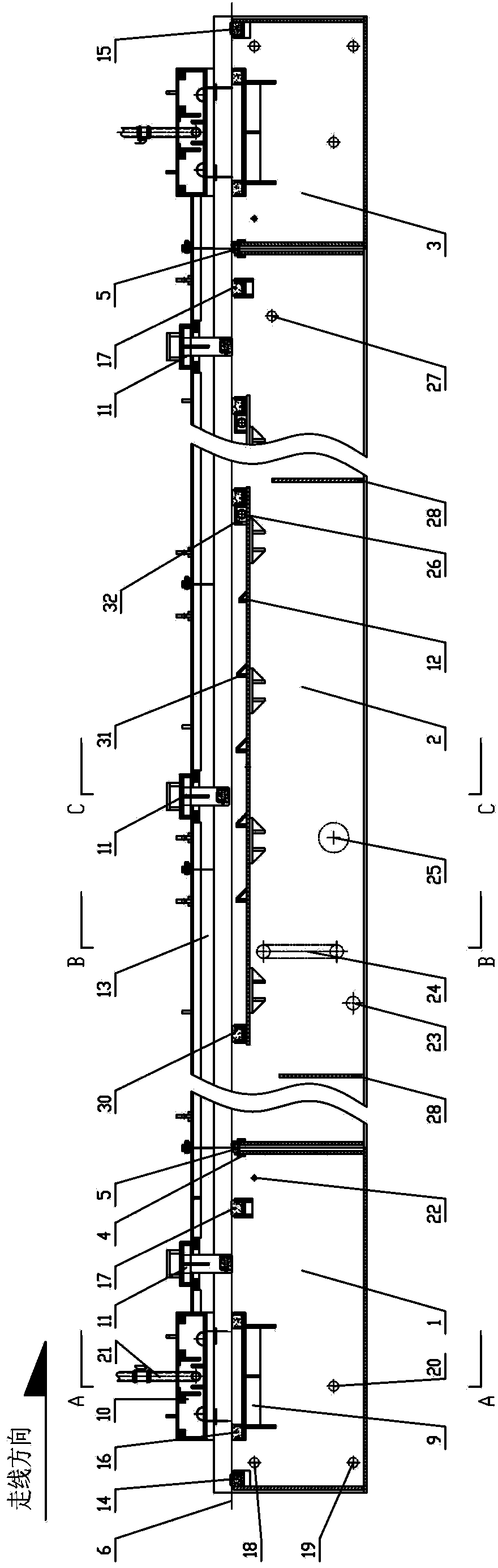

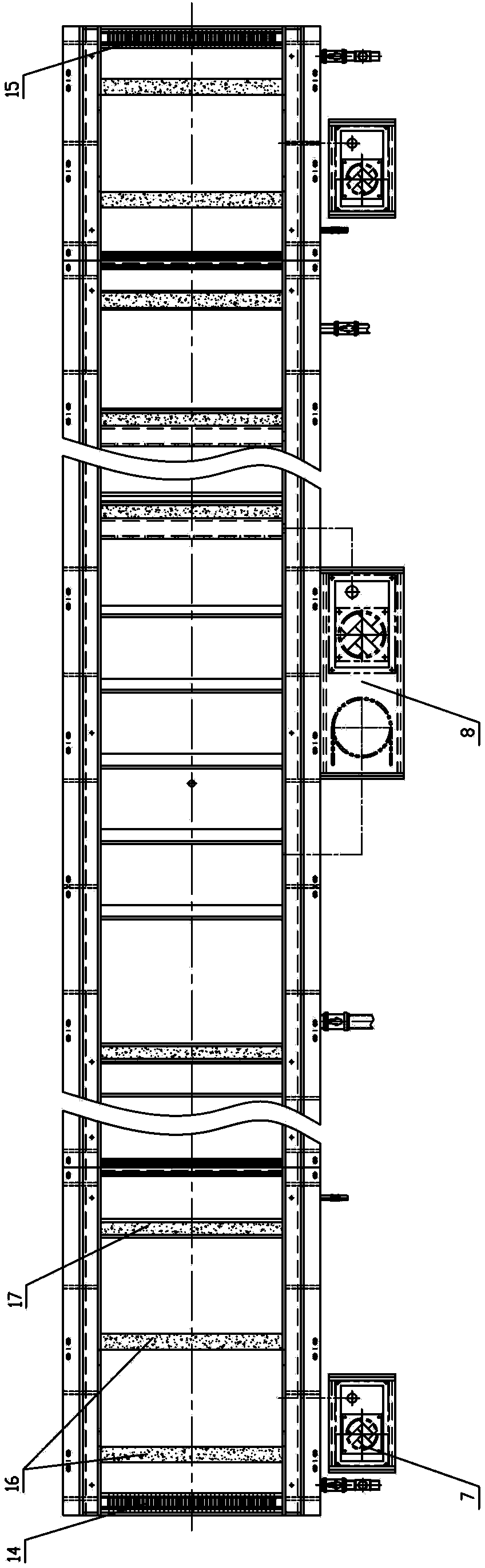

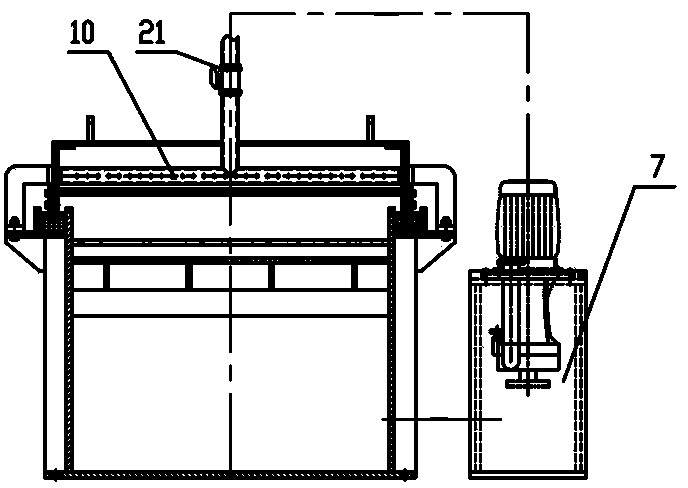

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0022] As shown in the figure: the steel wire closed smokeless pickling unit in the embodiment is mainly composed of the water curtain tank 1 for the incoming line, the main pickling tank 2, the water curtain tank for the outgoing line 3, the connecting plate for the tank body 4, and the grinding stone for supporting the line at the connection 5. Water curtain pump box 7, steam heating acid pump box 8, water curtain tank tray 9, water curtain cover 10, gland 11, pickling working tank 12, pickling main tank cover plate 13, incoming line branching grinding stone 14. Grinding stone for outgoing line and branching line 15, first grinding stone for supporting line 16, grinding stone for supporting line 17, overflow pipe 18, drain pipe 19, water pumping pipe 20, water inlet pipe 21, water adding pipe 22, acid discharge pipe 23, liquid Bit table 24, acid pumping pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com