Air-jet loom

An air-jet loom and air pump technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of narrow weft density range of woven fabrics, and achieve the effect of less equipment investment and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An air-jet loom comprises a shedding mechanism, an airflow weft insertion mechanism, a weft beating mechanism, a let-off mechanism, a coiling mechanism and other auxiliary mechanisms. Except for the following differences, other relevant components can be realized by adopting or referring to existing technologies.

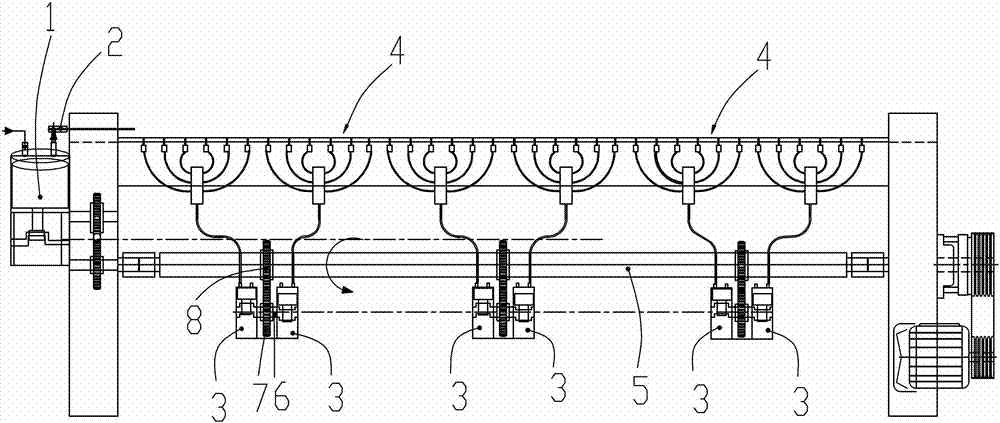

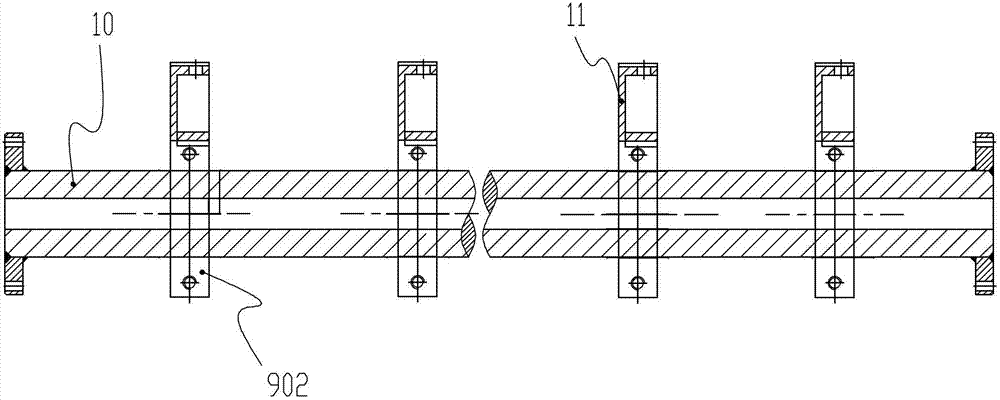

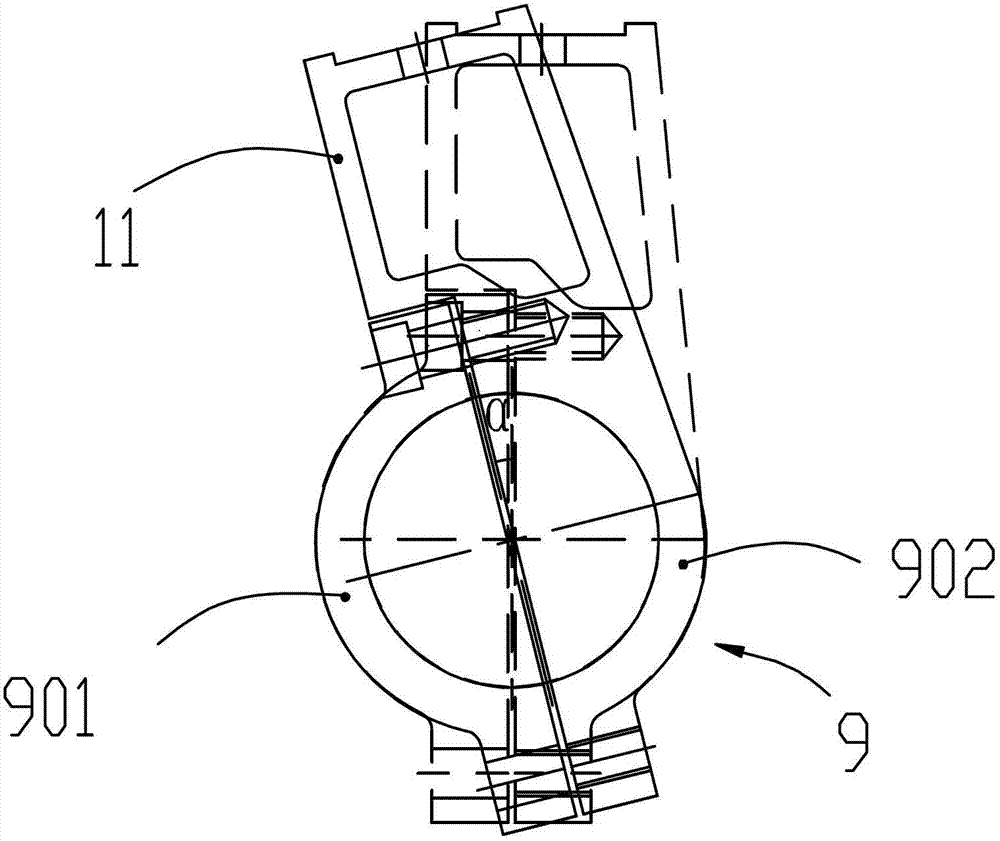

[0021] combine figure 1 , the above-mentioned airflow weft insertion mechanism includes a main air pump 1, a main nozzle 2, several auxiliary air pumps 3, an auxiliary nozzle group 4 having the same number as the auxiliary air pumps, and an air pump drive shaft 5; the above-mentioned main air pump is a plunger type air pump, and each auxiliary air pump Also all are plunger type air pumps, this example selects six auxiliary air pumps and six groups of auxiliary nozzle groups. The above-mentioned main nozzles are connected to the main air pump, and each auxiliary nozzle group is respectively connected to an auxiliary air pump, the main nozzle is fixed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com