Efficient oil bath type air filter

An air filter, oil bath type technology, applied in the direction of combustion air/combustion-air treatment, machine/engine, engine components, etc., can solve the problem of heavy-duty diesel trucks that cannot be applied to high-power, difficult to ensure uniform winding, and air filtration Eliminate problems such as heavy weight of the cleaner, and achieve the effect of reliable sealing, simple and compact structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

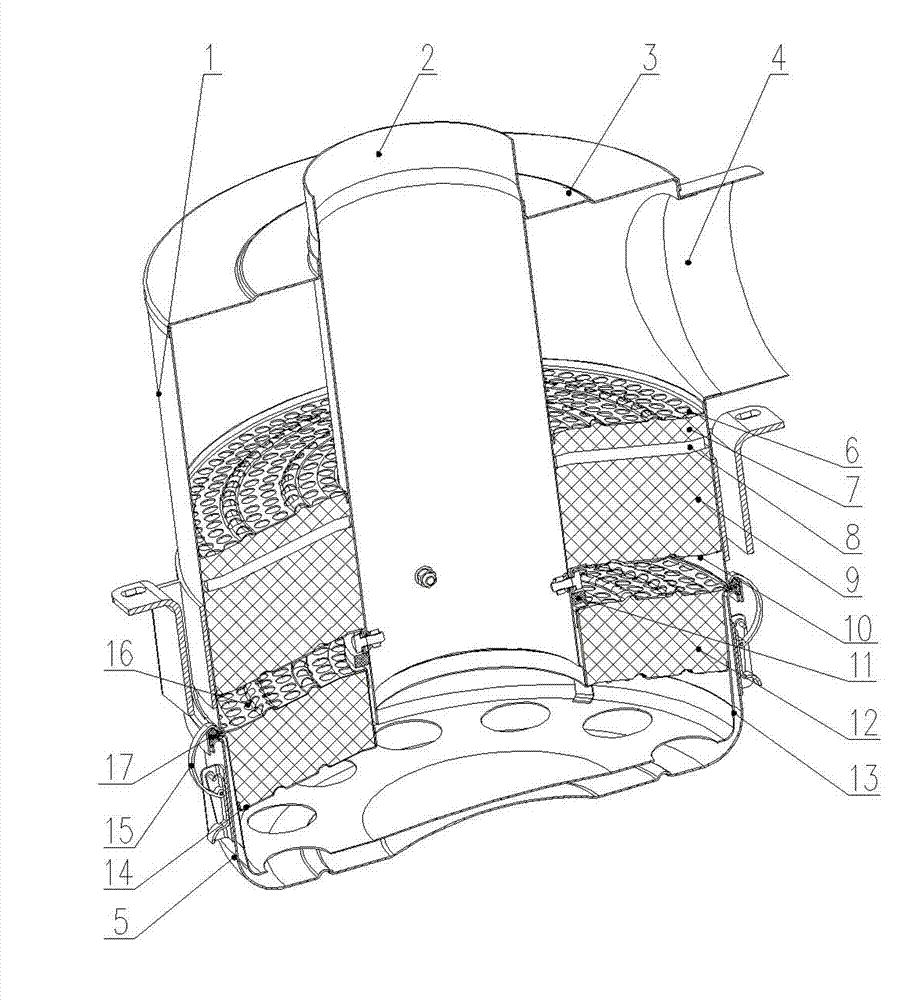

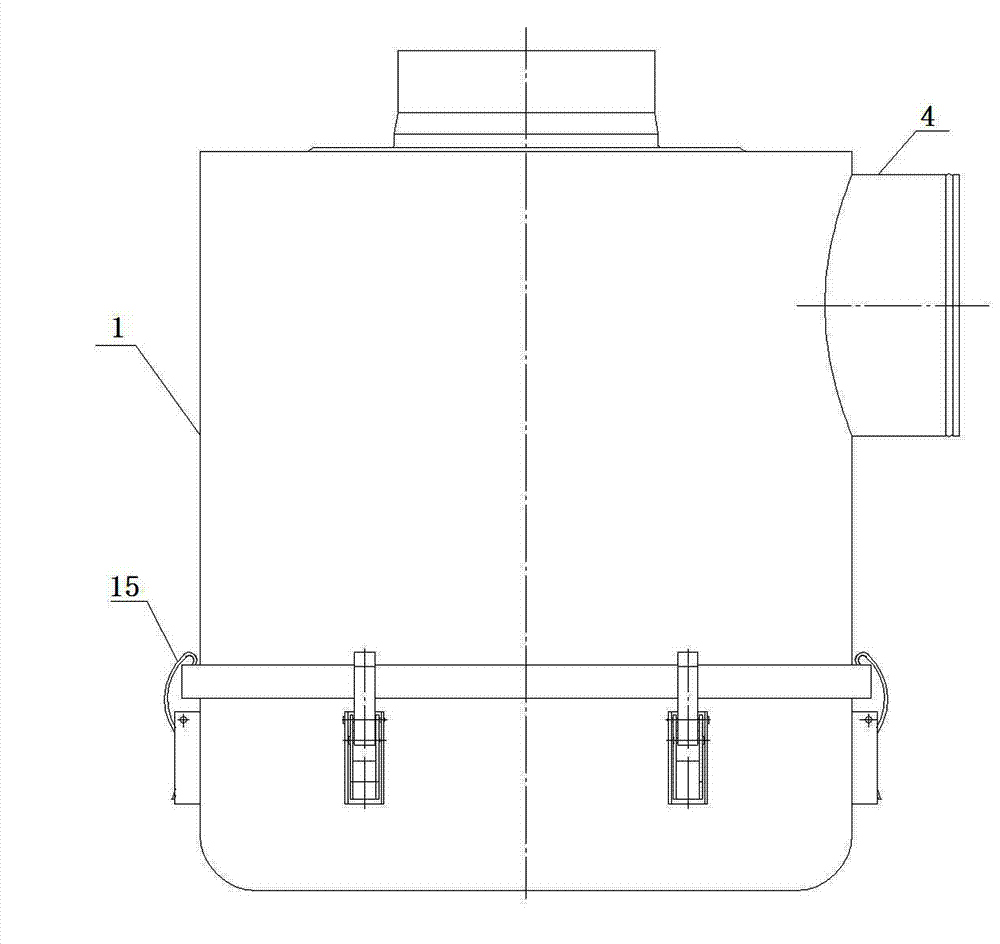

[0014] as attached figure 1 , 2 As shown, the present invention includes a filter housing 1, an upper end cover 3, a lower end cover 5, a clip 15, an air inlet cavity 2, a filter element, an air outlet 4 arranged on one side of the upper part of the filter housing 1 and an air outlet arranged at the lower end The oil storage tray 13 in the cover 5, the filter element is made of polyurethane material, which includes an upper filter element and a lower filter element 12, and the upper filter element and the lower filter element 12 are sequentially set in the air intake chamber 2 in the filter housing 1 On the outside, the upper filter element includes a first-level upper filter element 9 and a second-level upper filter element 7, and an expansion chamber 8 is arranged between the first-level upper filter element 9 and the second-level upper filter element 7, and the expansion chamber 8 is the first-level upper filter element 9 and the second-level upper filter element 7. The bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com