Thin high power LED (Light Emitting Diode) line lamp

An LED line light, high-power technology, applied in the direction of lampshade, cooling/heating device of lighting device, lighting and heating equipment, etc. Improve the effect of light output and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

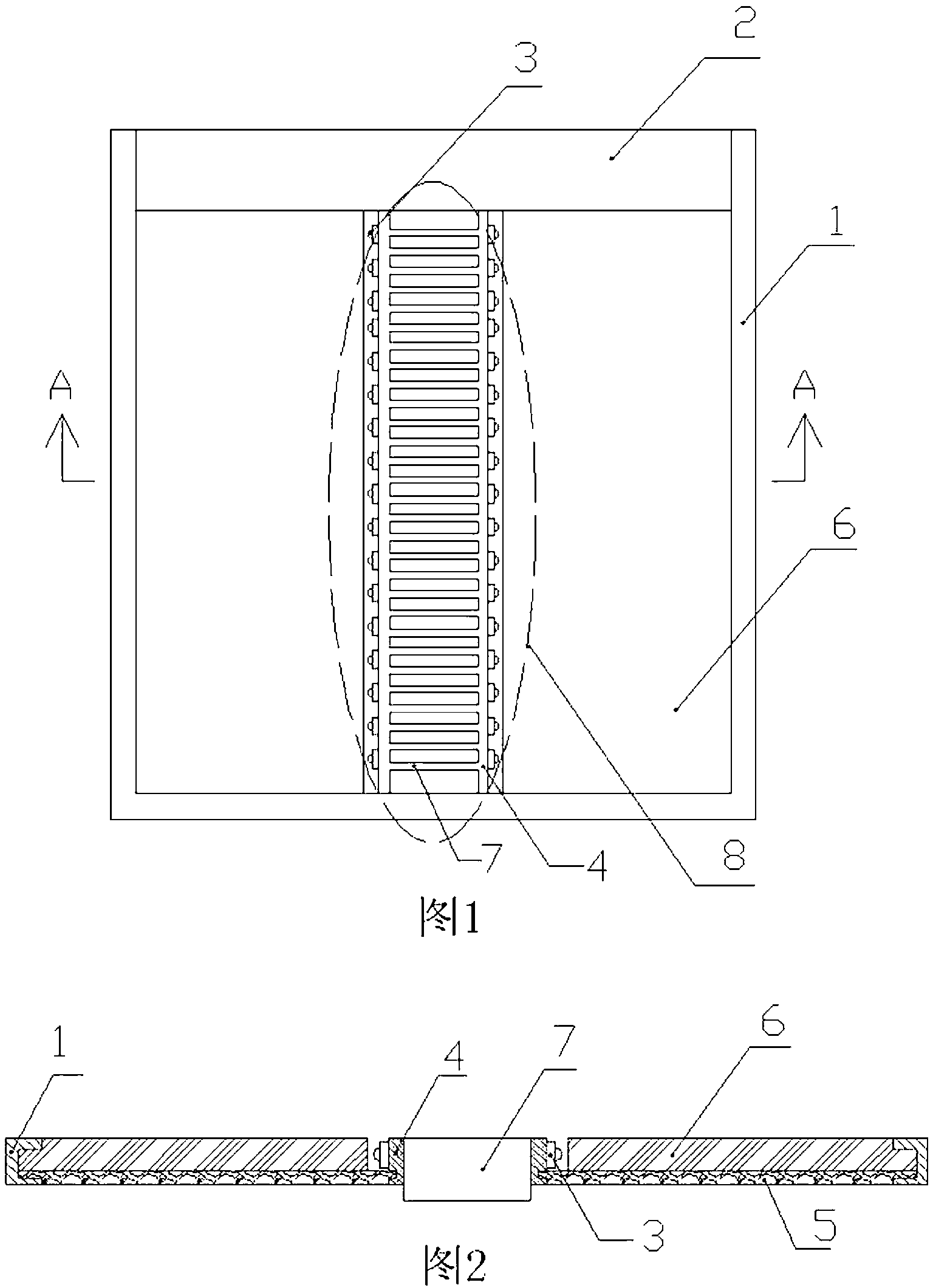

[0019] Embodiment one: if figure 1 , figure 2 As shown, the thin high-power LED line lamp of this embodiment is composed of a lamp housing 1, a lampshade 5, an LED light source 3, a radiator, and a drive power circuit 2 assembled in the lamp housing 1. The radiator adopts a ladder structure, and two Several pieces of heat dissipation fins 7 are clamped and fixed between the strip-shaped heat dissipation substrates 4, and the heat dissipation fins 7 are arranged in parallel at intervals along the direction perpendicular to the heat dissipation substrate 4, and the two single rows of LED lamp beads constituting the LED light source 3 are welded on the aluminum substrate Finally, it is connected to the heat dissipation substrate 4 on both sides of the ladder radiator. The LED light source 3 and the radiator together form a light emitting module 8. Two light guide plates 6 are placed side by side on both sides of the light emitting module 8. The two serve as the frosting of the l...

Embodiment 2

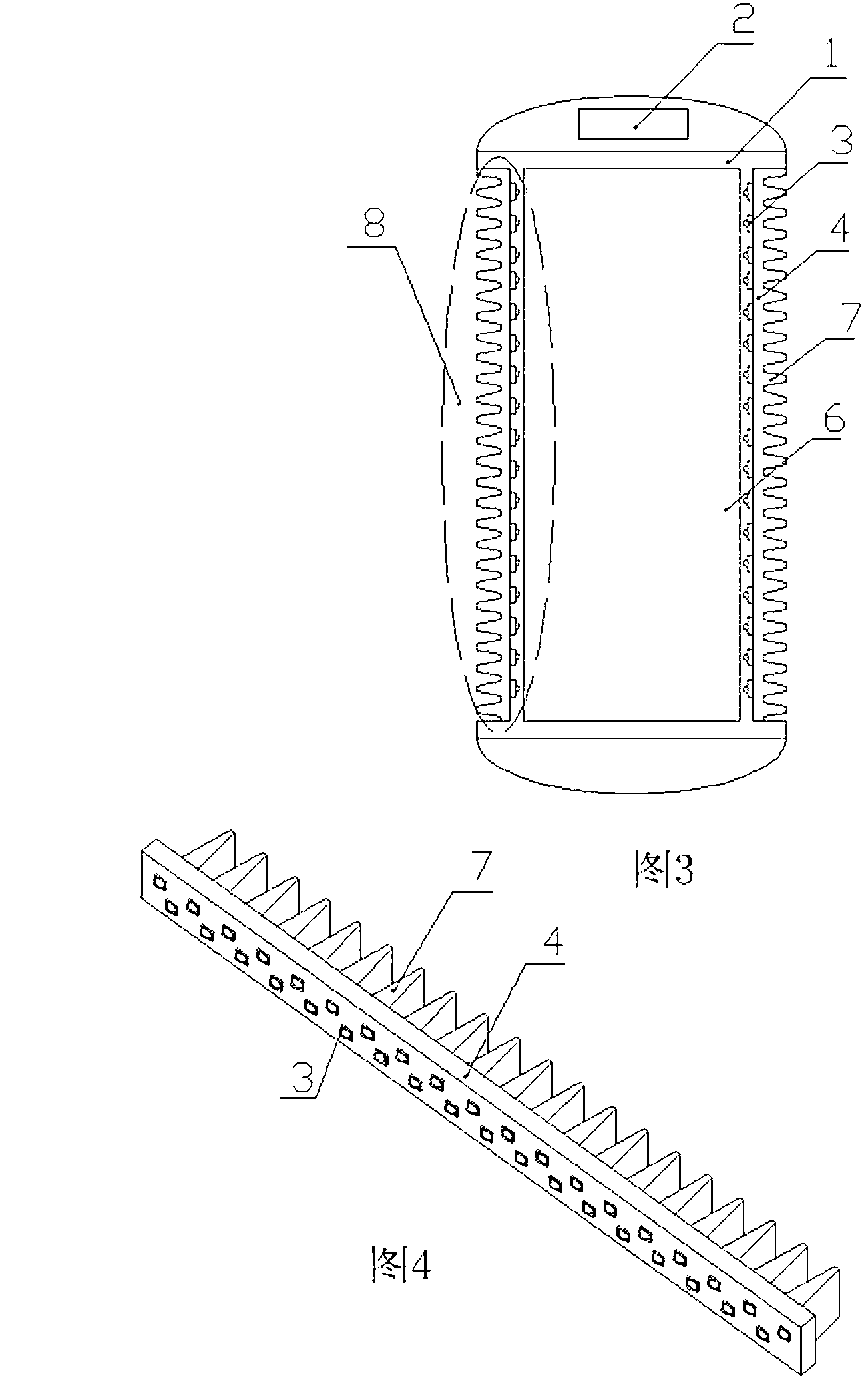

[0020] Embodiment two: if image 3 , Figure 4 As shown, the thin high-power LED line light only contains one light guide plate 6, and two sets of light-emitting modules 8 clamp the light guide plate 6 in the middle. The light-emitting module 8 is composed of an LED light source 3 and a heat sink. The heat sink is composed of a heat dissipation substrate 4 with a printed circuit layer and heat dissipation fins 7 arranged in parallel at intervals along a direction perpendicular to the heat dissipation substrate. Distributed on the heat dissipation substrate 4, the distance between any two adjacent LED lamp beads is equal. The thin high-power LED line lamp adopting this structure has better heat dissipation effect and simpler structure, and is especially suitable for single-unit power Lamp beads make LED light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com