Liquid crystal lens

A technology of a liquid crystal lens and a liquid crystal layer, which is applied in the directions of lenses, optics, instruments, etc., can solve the problems of complex design of the liquid crystal lens structure 200, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

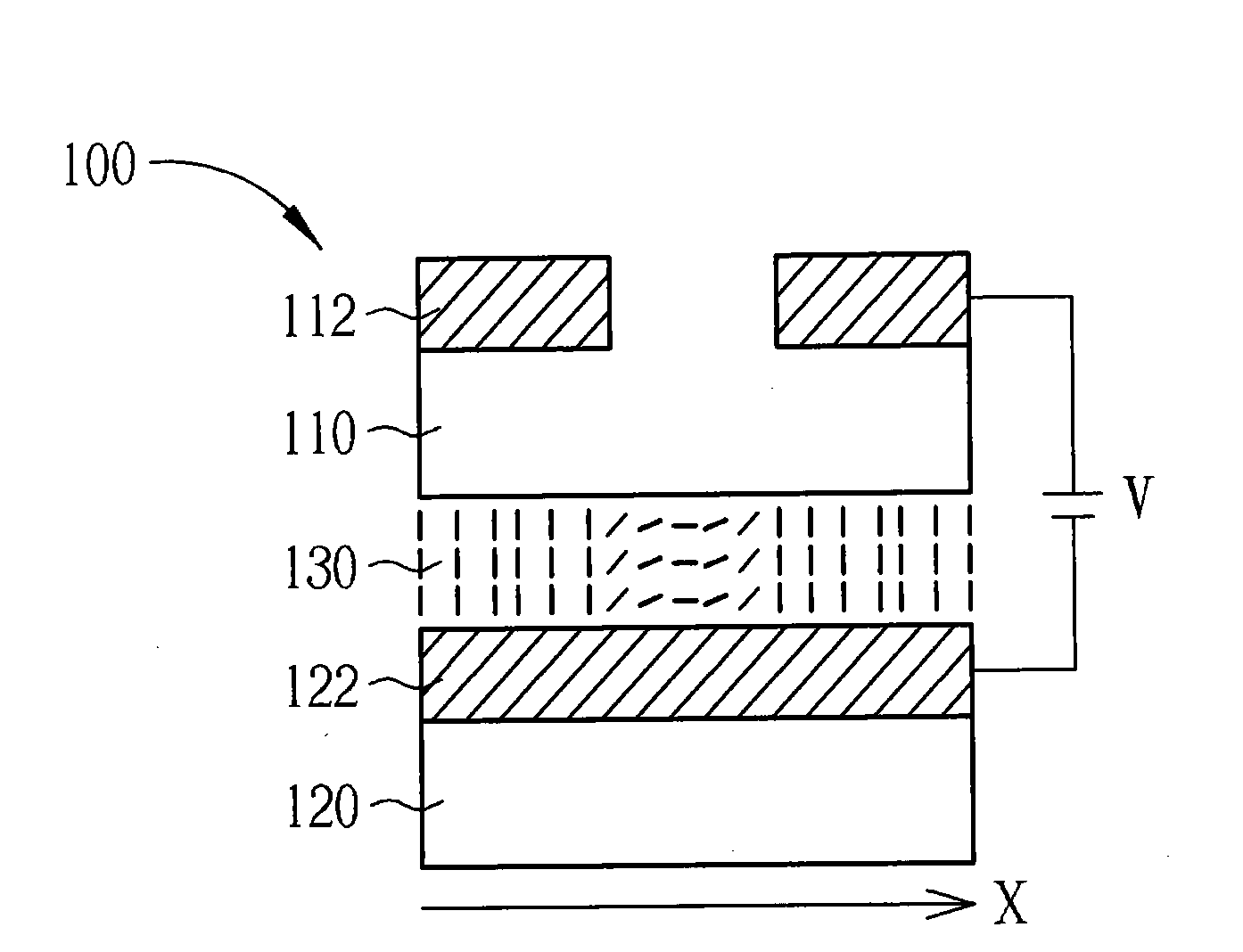

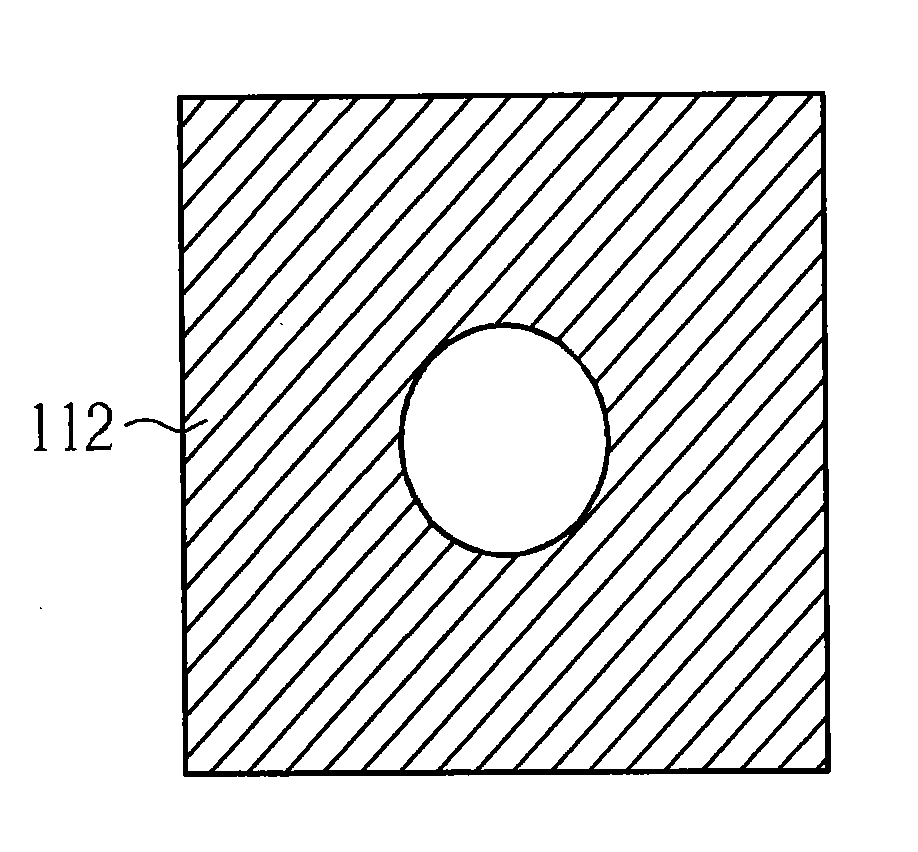

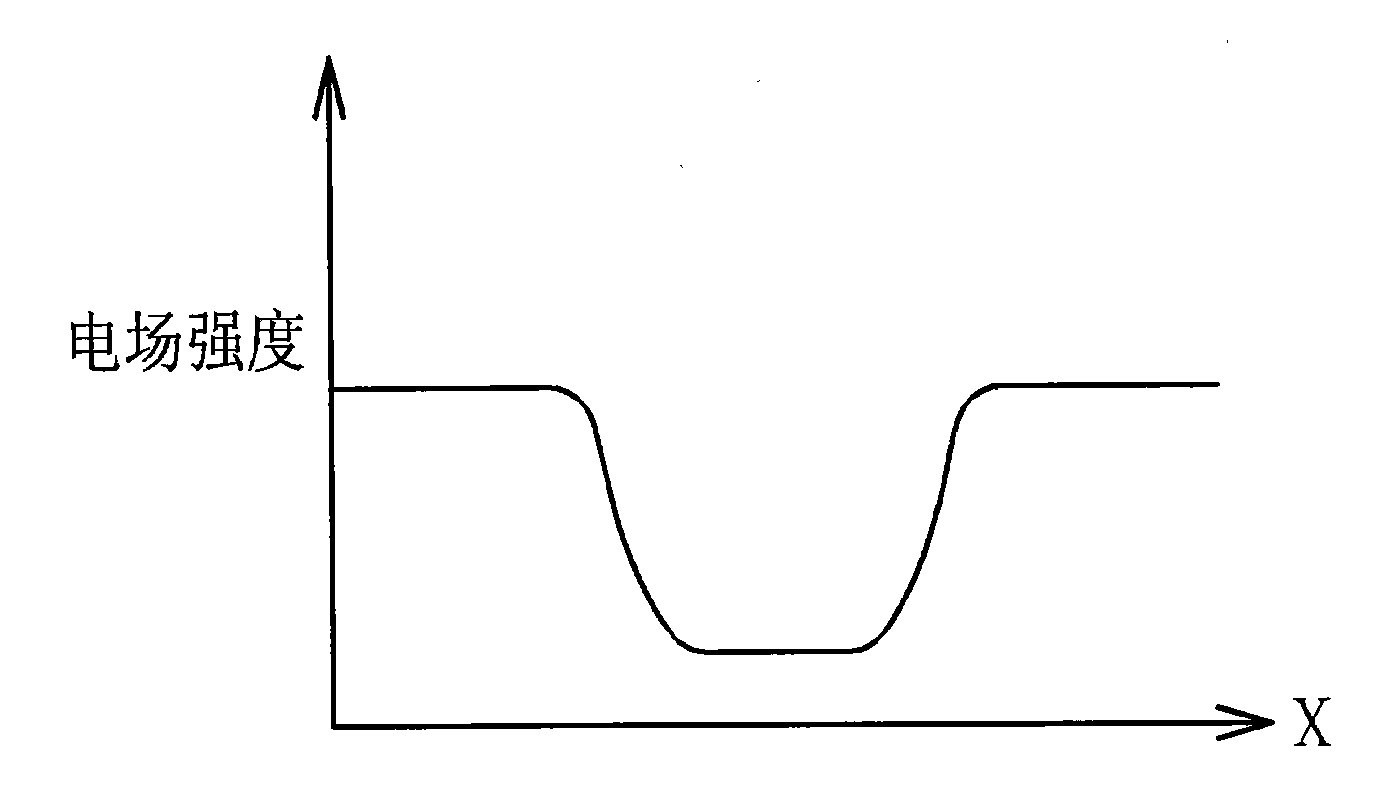

[0031] Please refer to Figure 3A , Figure 3A It is a schematic diagram of a liquid crystal lens 300 according to an embodiment of the present invention. Such as Figure 3A As shown, the liquid crystal lens 300 includes two glass layers 310 and 320 , two ITO electrode layers 312 and 322 respectively formed on the two glass layers 310 and 320 , and a liquid crystal layer 330 . Figure 3B Shown is a top view of the ITO electrode layer 312, wherein the ITO electrode layer 312 has a plurality of concentric ring electrodes (in this embodiment, three concentric ring electrodes 312_1-312_3), and adjacent The distance between two concentric circular electrodes decreases along the outward radial direction, wherein the word "distance" refers to the minimum distance between two adjacent concentric circular electrodes. In addition, the connecting electrodes 350 are used to connect the concentric circular electrodes 312_1 - 312_3 , and the concentric circular electrodes 312_1 - 312_3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com