Optical proximity correction method

An optical proximity correction and exposure technology, which is applied in the semiconductor field, can solve the problems of long cycle time and increase the production cost of semiconductor foundries, and achieve the effect of saving process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

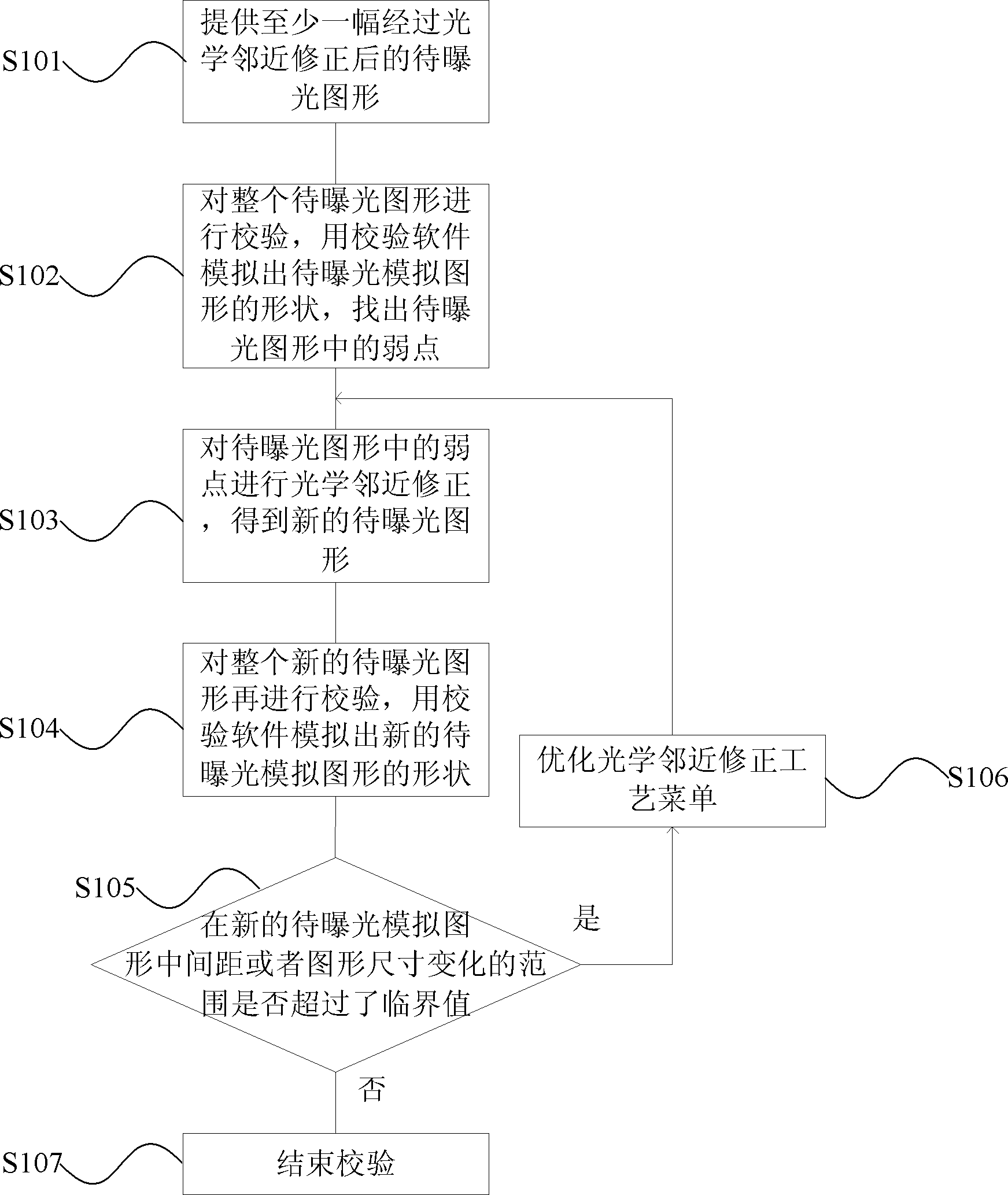

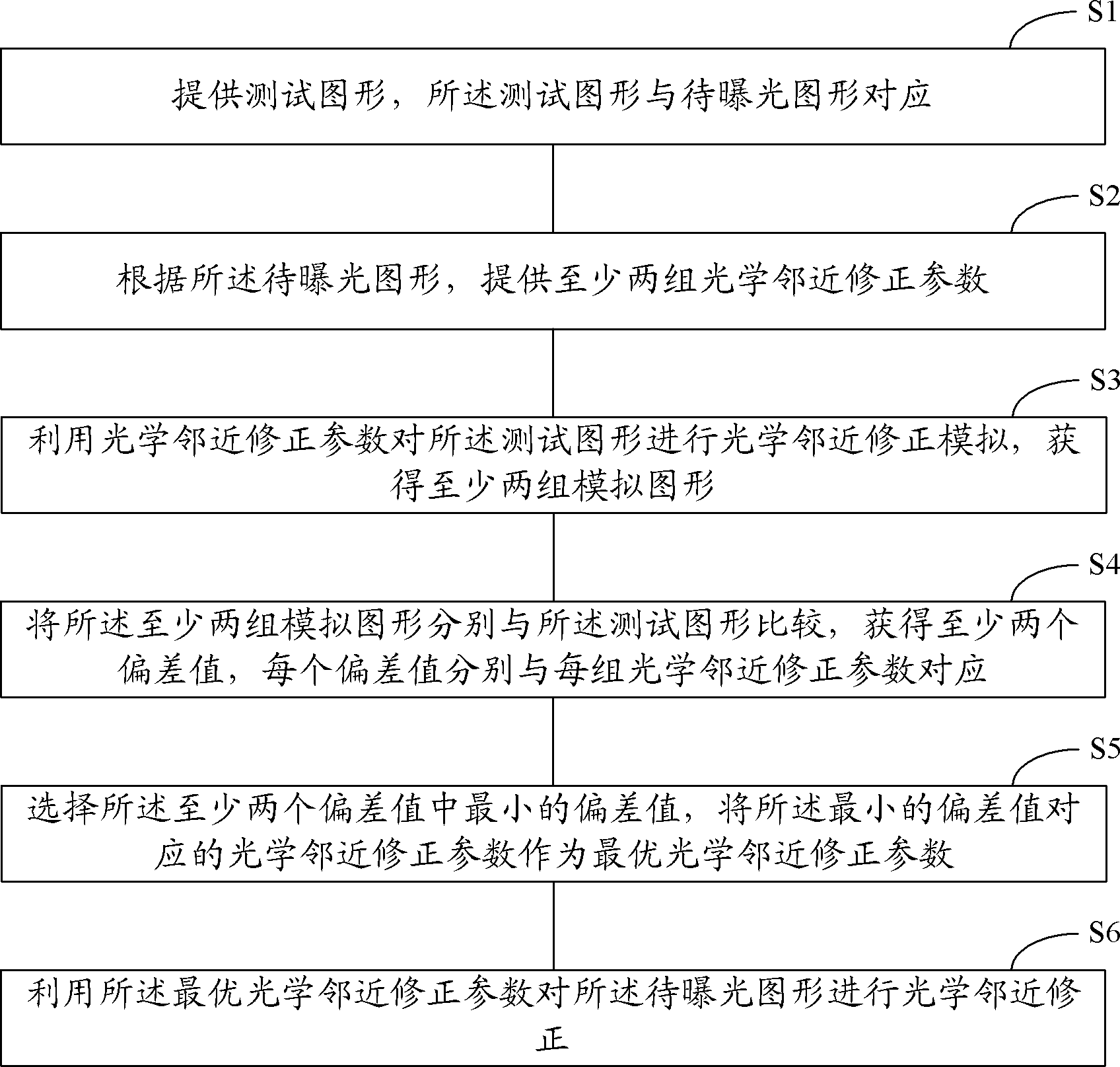

Method used

Image

Examples

Embodiment Construction

[0025] The inventor found that the optical proximity correction parameters of the optical proximity correction program need to be adjusted several times during the optical proximity correction process, which makes the optical proximity correction take a long time, and it is impossible to verify whether the optical proximity correction parameters are optimal, so that the optical proximity correction The effect of the proximity correction is not necessarily the optimal effect, and, with the reduction of the semiconductor feature size, the adjustment of the optical proximity correction parameters is more frequent, thereby further increasing the time of the optical proximity correction.

[0026] The inventor considers that if the optimal optical proximity correction parameters can be determined before the optical proximity correction is performed on the graphics to be exposed, so as to use the optimal optical proximity correction parameters to perform optical proximity correction on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com