Layout structure of capacitive touch panel

A touch panel and layout structure technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of increasing costs, reduce manufacturing costs, simplify the number of masks and process complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

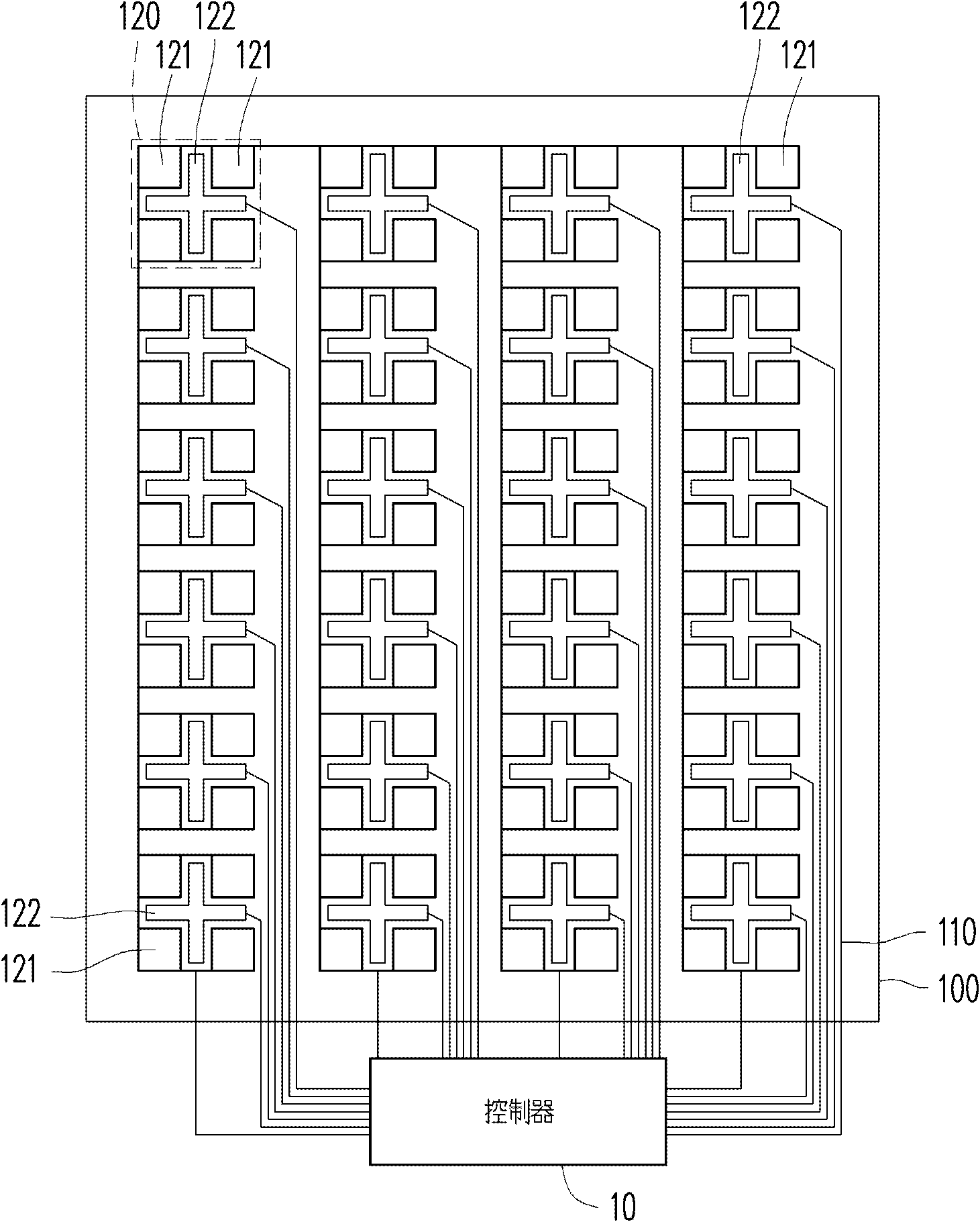

[0020] figure 1 It is a schematic diagram illustrating the layout structure of a capacitive touch panel 100 according to an embodiment of the present invention. The layout structure of the capacitive touch panel 100 includes a plurality of electrical paths 110 and a plurality of first touch units (touch units, such as figure 1 Shown touch unit 120). For the implementation of other touch units in the capacitive touch panel 100 , reference may be made to the related description of the touch unit 120 . In this embodiment, the substrate can be made of polycarbonate (Polycarbonate, PC), polyethylene (Polyethylene, PE), polyethylene terephthalate (polyethylene terephthalate, PET), polymethyl methacrylate (PolyMethyl MethAcrylate, PMMA) or transparent materials such as glass substrates. The electrical path 110 and the first touch unit 120 can be made of any light-transmitting conductive material, such as nanometer indium-tin oxide (ITO) and the like.

[0021] Each first touch uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com