Four-way triangle three lead wiring method of double layer winding of stator and rotor of three-phase asynchronous motor

A double-layer winding, three-phase asynchronous technology, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of waste of manpower, material resources, financial resources and time, motor burnout, and many welding joints, etc., to reduce maintenance times, Less error-prone and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

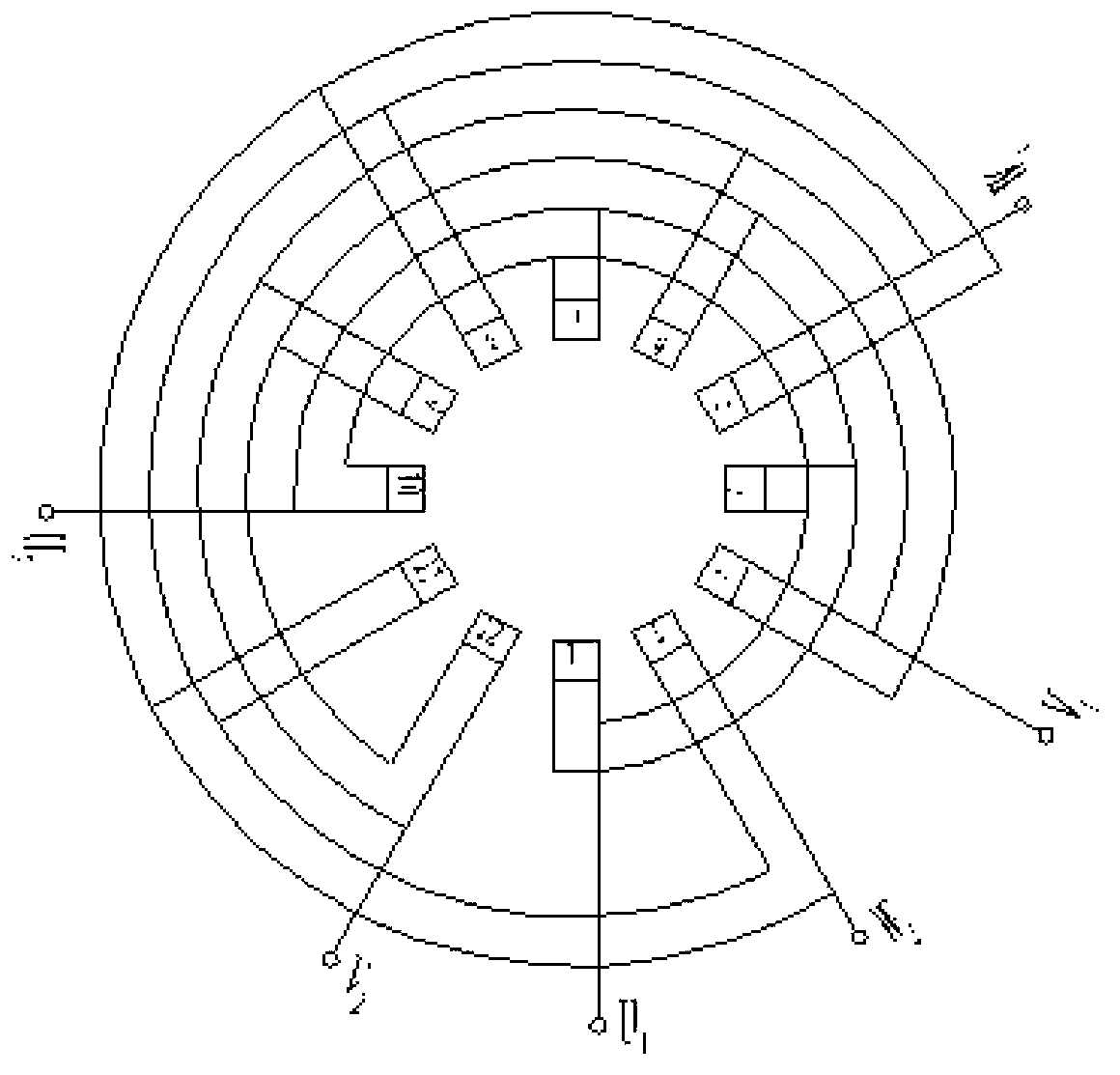

[0050] Three-phase asynchronous motors for cooling towers in hot rolling mills

[0051] Model Y225M-4-45kw, insulation class is B, speed is 1480r / min, frequency is 50HZ, power is 45kw, noise limit is 840dB(A), power factor is 0.87, current is 83.2A, voltage is 380V, protection class is 2P44, standard number JBT06161999.

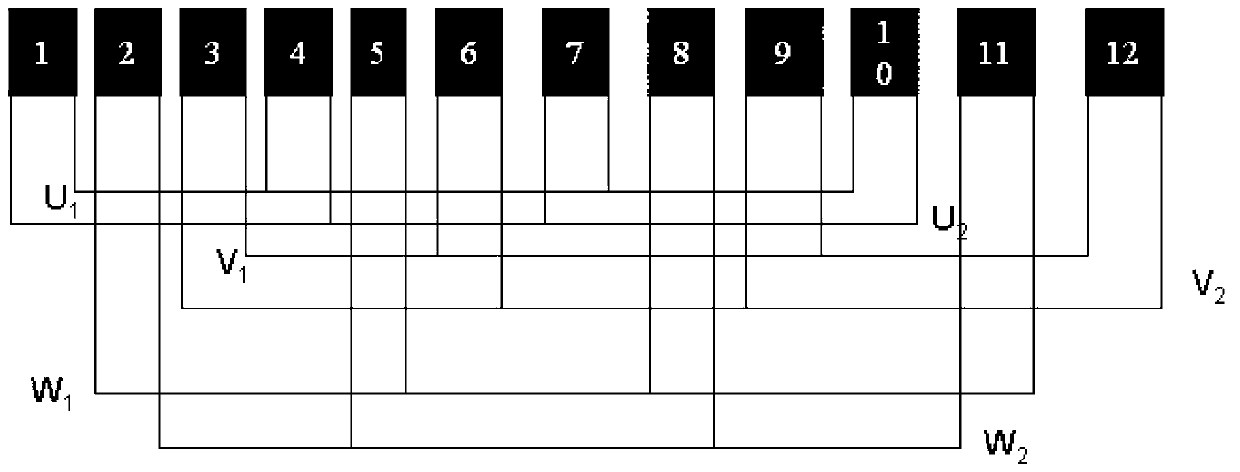

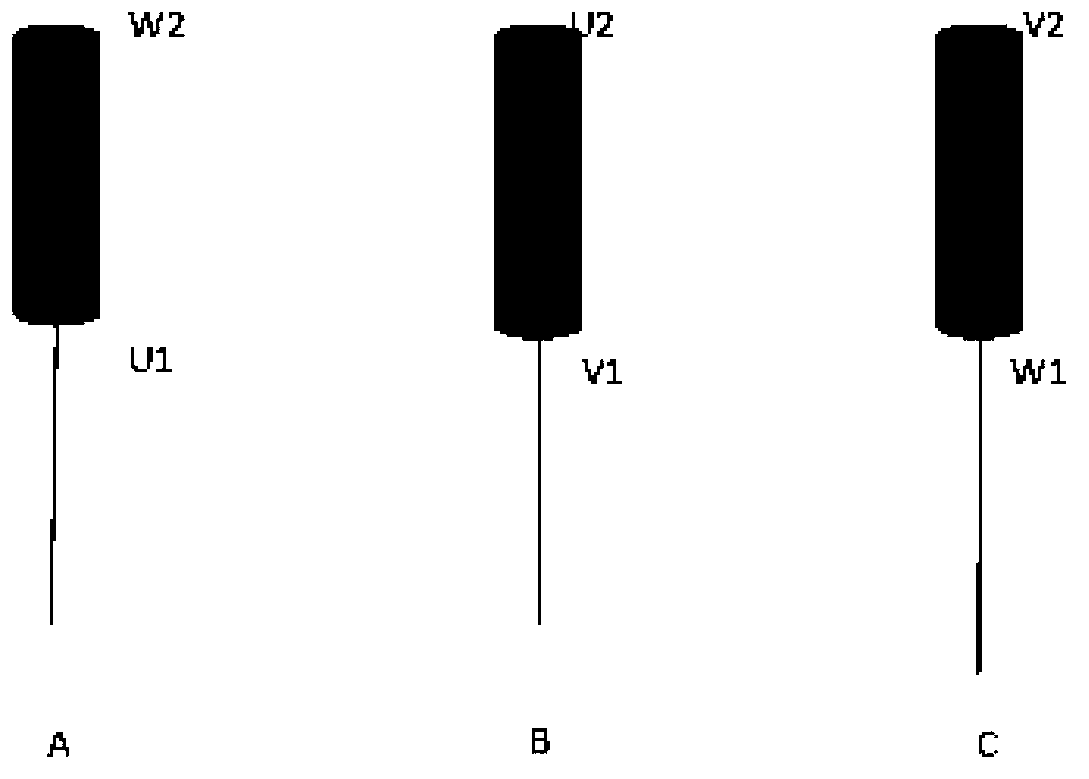

[0052] The motor Z=48, q=4, pitch 1-12

[0053] Wire Gauge: φ 1 =φ 2 =1.04

[0054] φ 1 =1.06 N=22

[0055] First press 4 groups to wind 12 wire packages on the winding machine. When inserting the wires, the pitch is 1-12. After all the wires are embedded, find the two adjacent wire packages 1 and 2 from the outside. Heads of packs 1 and 2, count 1-4 from pack 1, take tails of packs 4 and 5, count 1-4 from pack 4, take heads of packs 7 and 8, count 1- 4. Take the tails of wire packs 10 and 11, twist the 8 wires into a pile to get a lead wire A, and connect B and C in the same way

[0056] After comparison, in the connection method, each motor can save...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com