Wiper linkage

A link mechanism and wiper technology, which can be used in mechanical equipment, vehicle cleaning, vehicle maintenance, etc., can solve problems such as the inability of advantages to play a role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

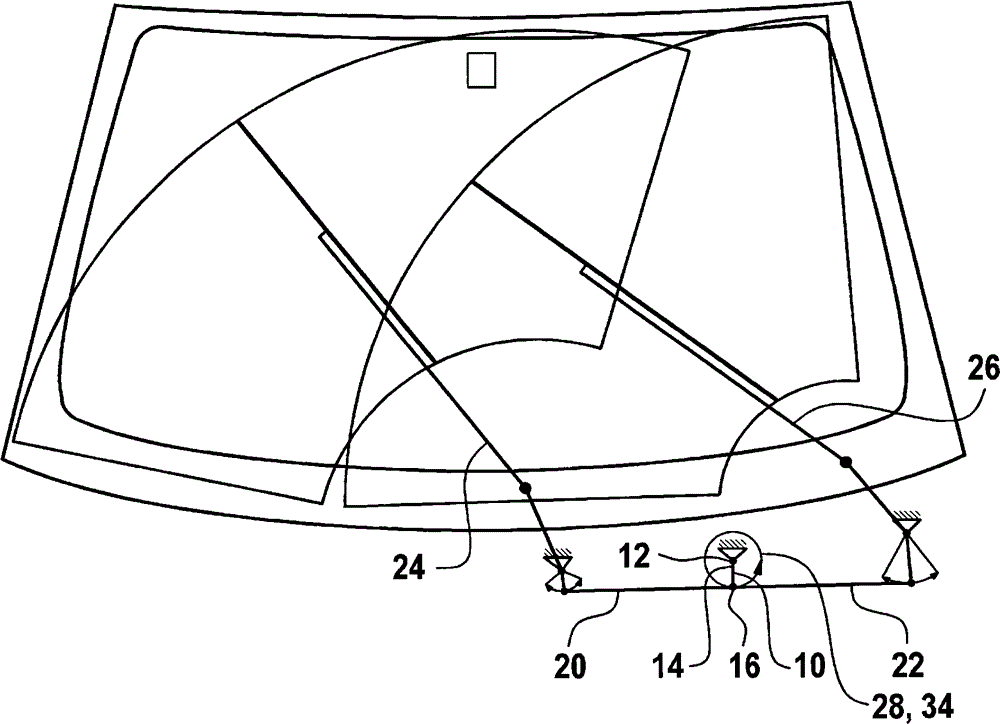

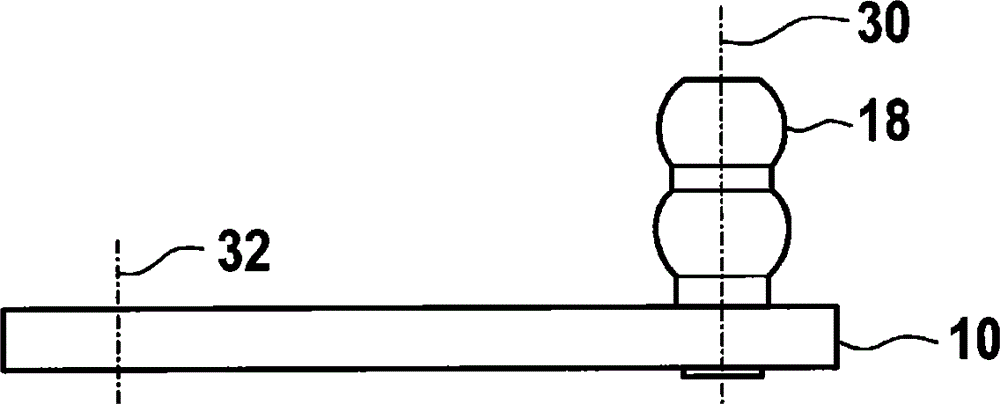

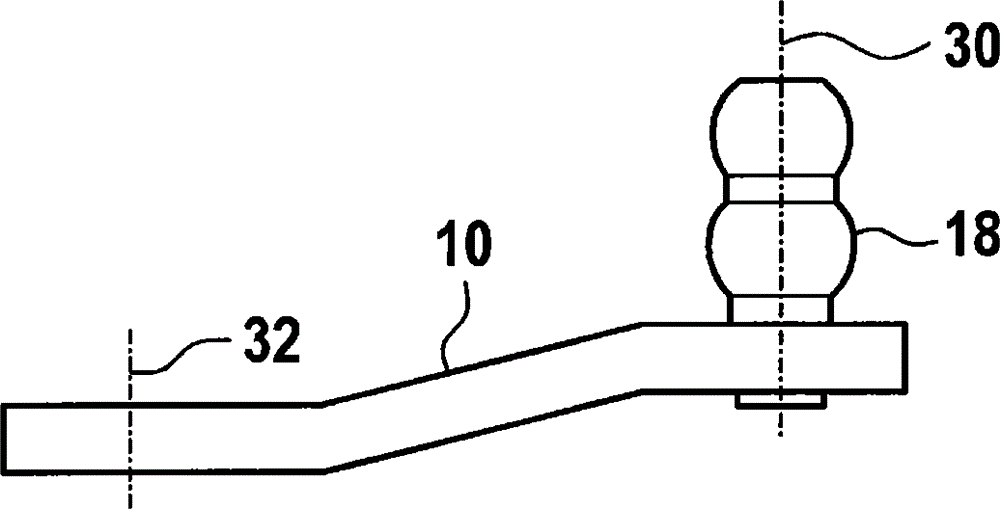

[0025] figure 1A schematic diagram showing the arrangement of a synchronously operating wiper system with a known wiper linkage for a window washing system of a motor vehicle, the wiper linkage having a motor crank 10. The motor crank is connected to the drive motor through a connecting element 12 in the form of an output shaft. The motor crank 10 is here connected at a first end section 14 to a connecting element 12 . At a second end section 16 opposite the first end section 14, the motor crank has a figure 2 and image 3 The double ball stud 18 shown in , at which the figure 2 and image 3 The first hinge lever 20 and the second hinge lever 22 are not shown. A window wiper arm 24 designed for the passenger side of the motor vehicle is arranged on the first hinge lever 20 and a second hinge lever 22 is connected to a window wiper arm 26 arranged on the driver's side of the motor vehicle . This known synchronously operating wiper system has a window wiper arm 24 for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com