Rolling bearing cages and rolling bearings

A technology of rolling bearings and cages, applied in the field of rolling bearings, can solve problems such as non-uniformity, expensive construction, and complexity, and achieve the effects of avoiding collisions, improving service life, and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

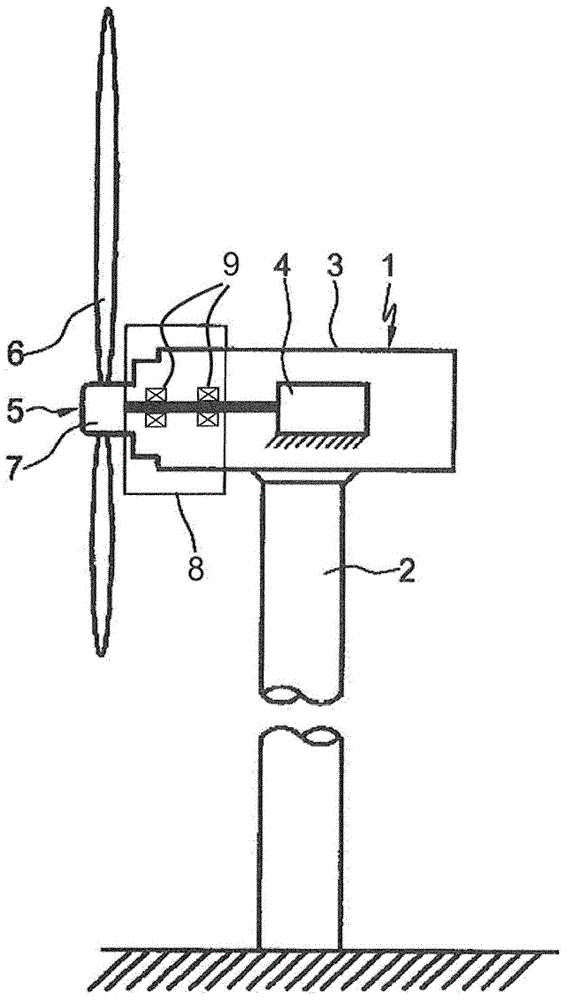

[0032] figure 1 A wind power plant 1 is shown which comprises a rotor mounting by means of two rolling bearings according to the invention. The wind power plant 1 comprises a machine tower 2 on which a nacelle 3 with a generator 4 and a wind-driven rotor 5 having a rotor hub 7 carrying a plurality of rotor blades 6 is arranged. The rotor 5 is carried by a rotor bearing 8 . The rotor bearing 8 comprises two rolling bearings 9 according to the invention, for example two tapered roller bearings in an O-arrangement.

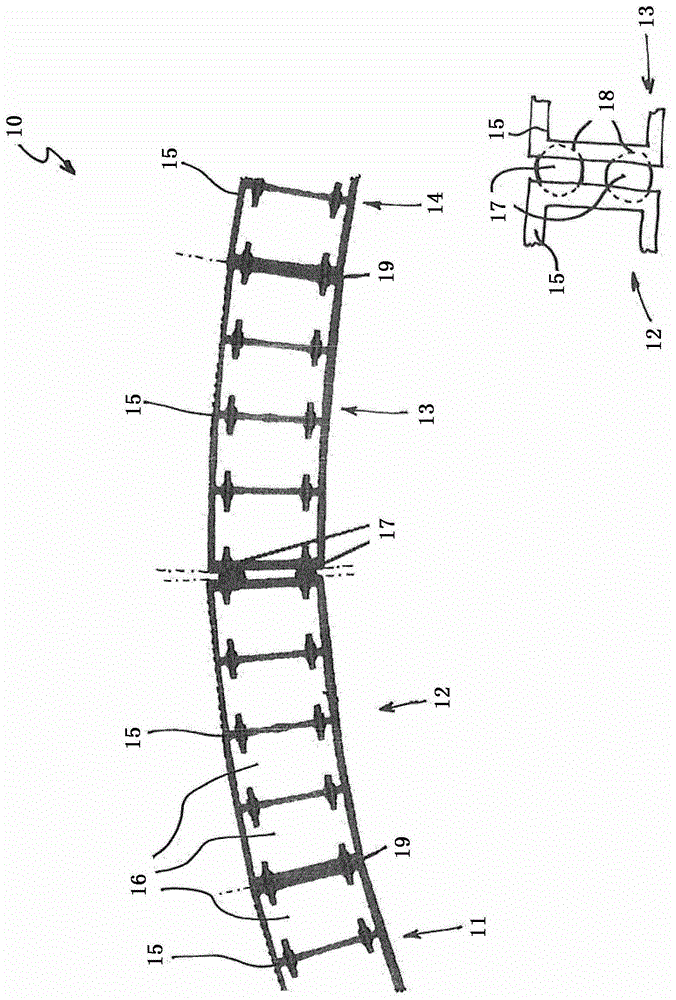

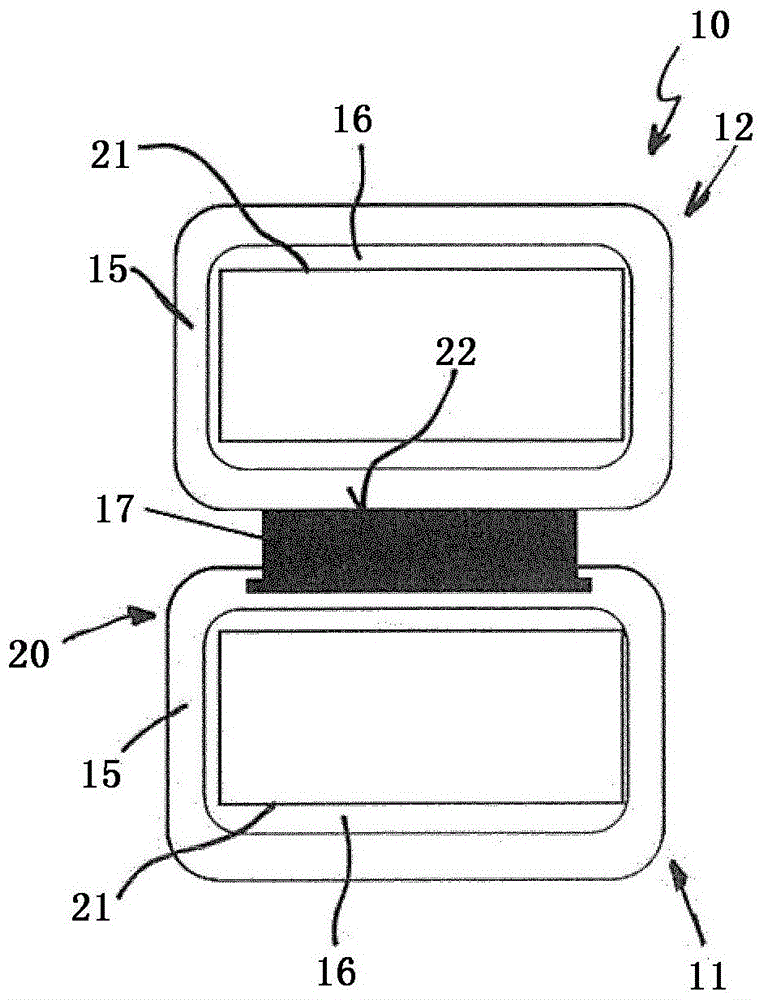

[0033] figure 2 A first embodiment of a rolling bearing cage 10 according to the invention is shown. The rolling bearing cage is designed as a rolling bearing cage 10 of a tapered roller bearing and is partially shown in a schematic plan view.

[0034] The rolling bearing cage 10 comprises a plurality of segments arranged loosely in the circumferential direction, of which four segments 11 , 12 , 13 , 14 are (partially) shown. Each segment 11 , 12 , 13 , 14 has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com