Sintered stator-cover unit and camshaft adjuster

A camshaft adjuster and stator technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of high manufacturing consumption and installation consumption, and achieve the effect of shortening manufacturing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

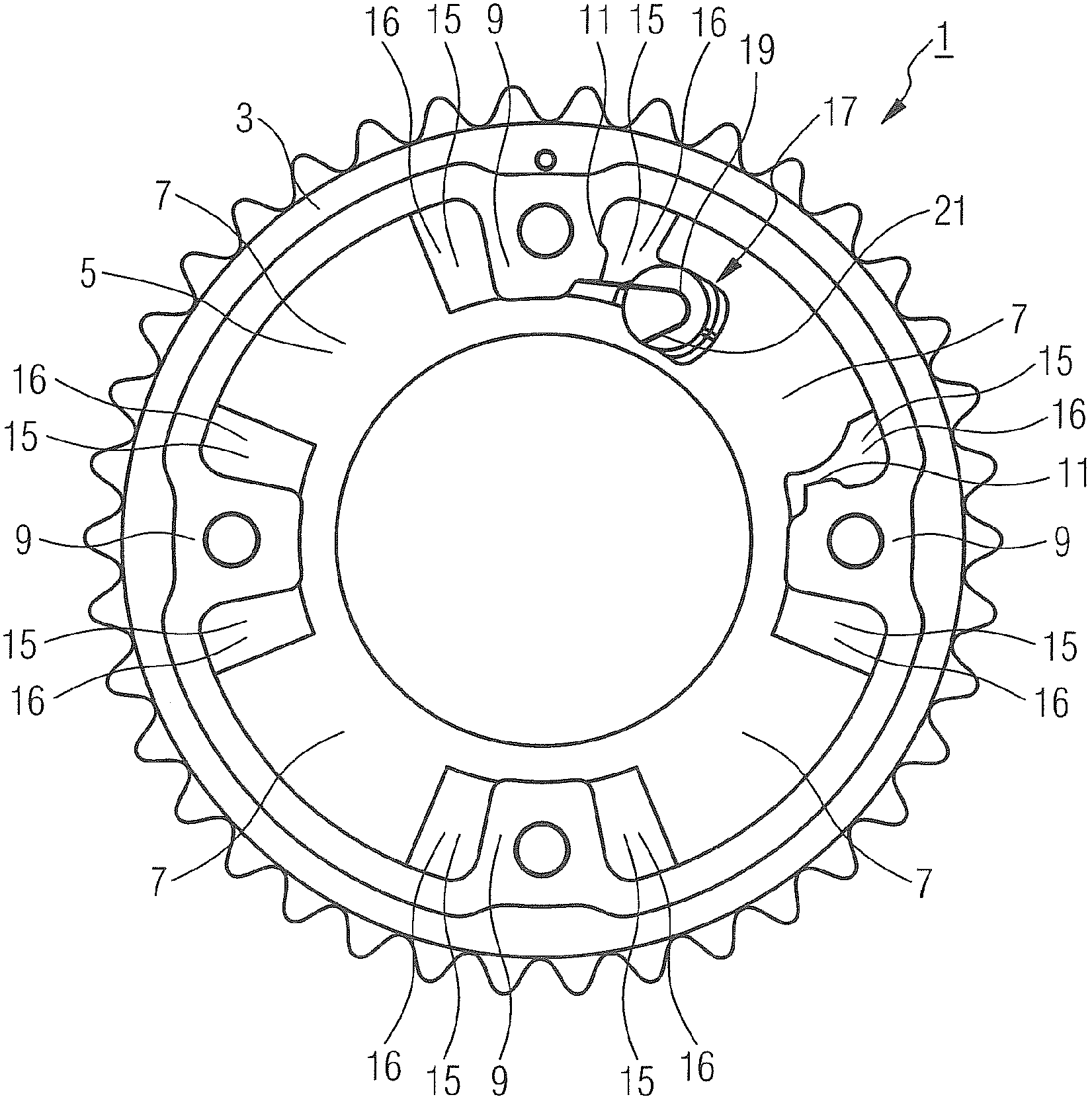

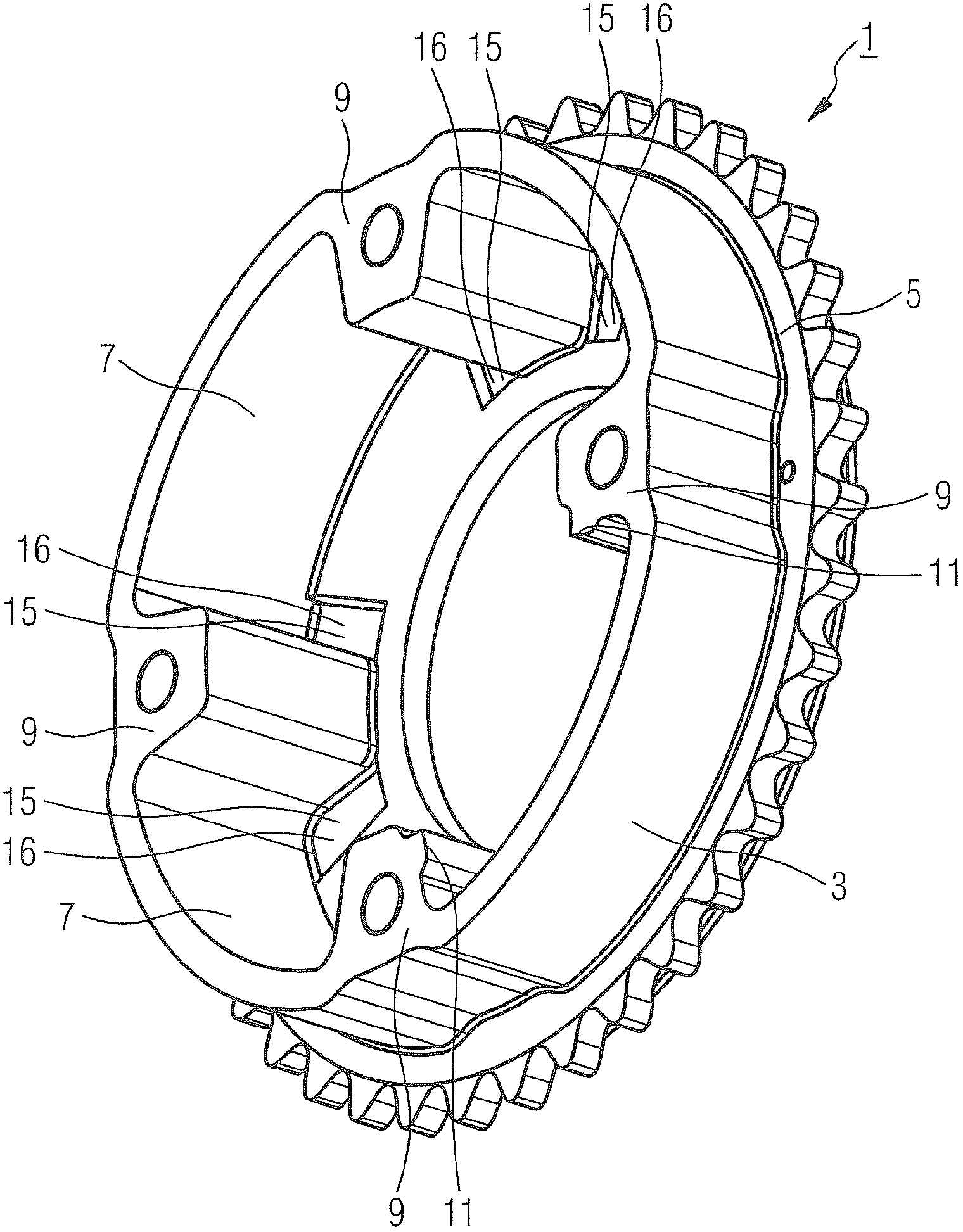

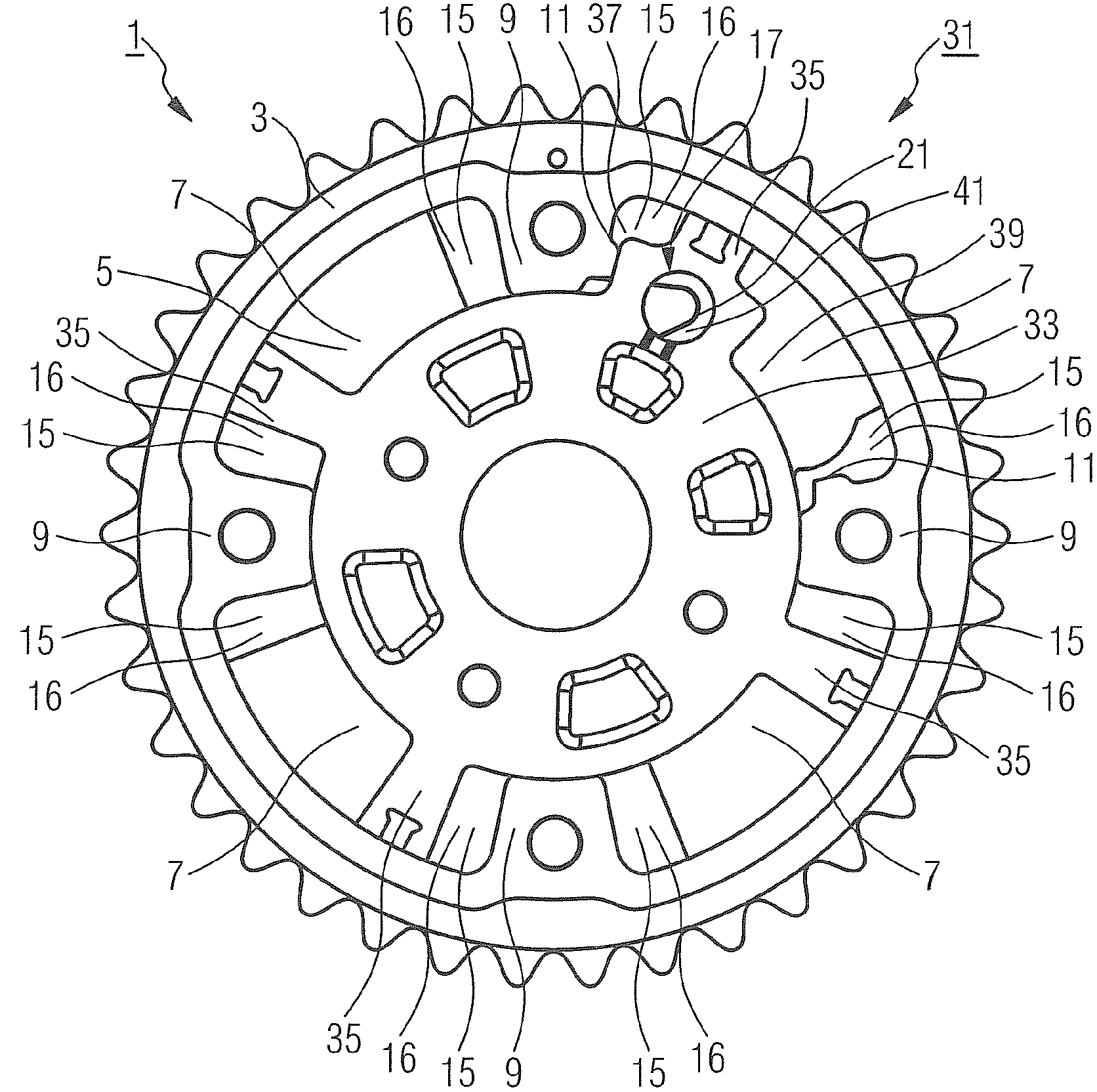

[0044] figure 1 The stator-cover unit 1 with the stator 3 and the locking cover 5 is shown in plan view. The stator-cover unit 1 , which is also referred to as a so-called stator can, is produced in one piece by means of a sintering method. In addition to simple production, this ensures the tightness of the stator-cover unit 1 and reduces error tolerances. Post-processing is likewise no longer necessary or only necessary to a small extent. The stator-cover unit 1 can be connected in a rotationally fixed manner to the drive wheel driven by the crankshaft, which in figure 1 is not shown in .

[0045] The stator-cover unit 1 is produced as a component by sintering from sintered steel Sint D11. The sintered steel has a carbon content of 0.6 mass % and a carbon content of 6.8 g / cm 3 Density. The stator-cover unit 1 is locally hardened in the region of the link groove 17 by temperature treatment and has a Vickers hardness of 500 HV5 there. The material of the stator-cover uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com