Heat exchanger

A technology for heat exchangers and heat exchangers, which is applied to heat exchanger fixing, heat exchange equipment, heat exchangers, etc., can solve the problems of increased thickness, inability to implement stamping process, etc., and achieve the effect of increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

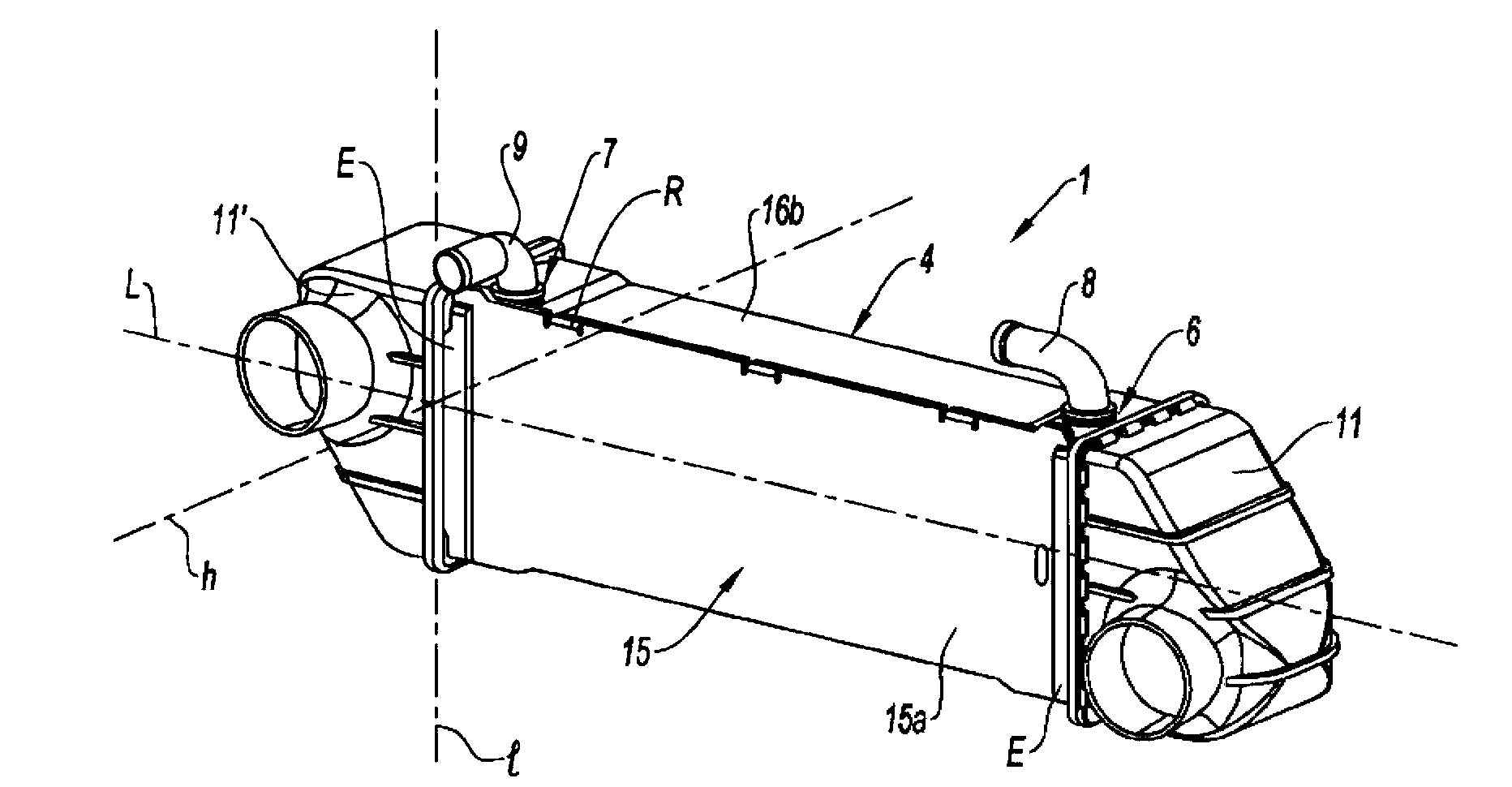

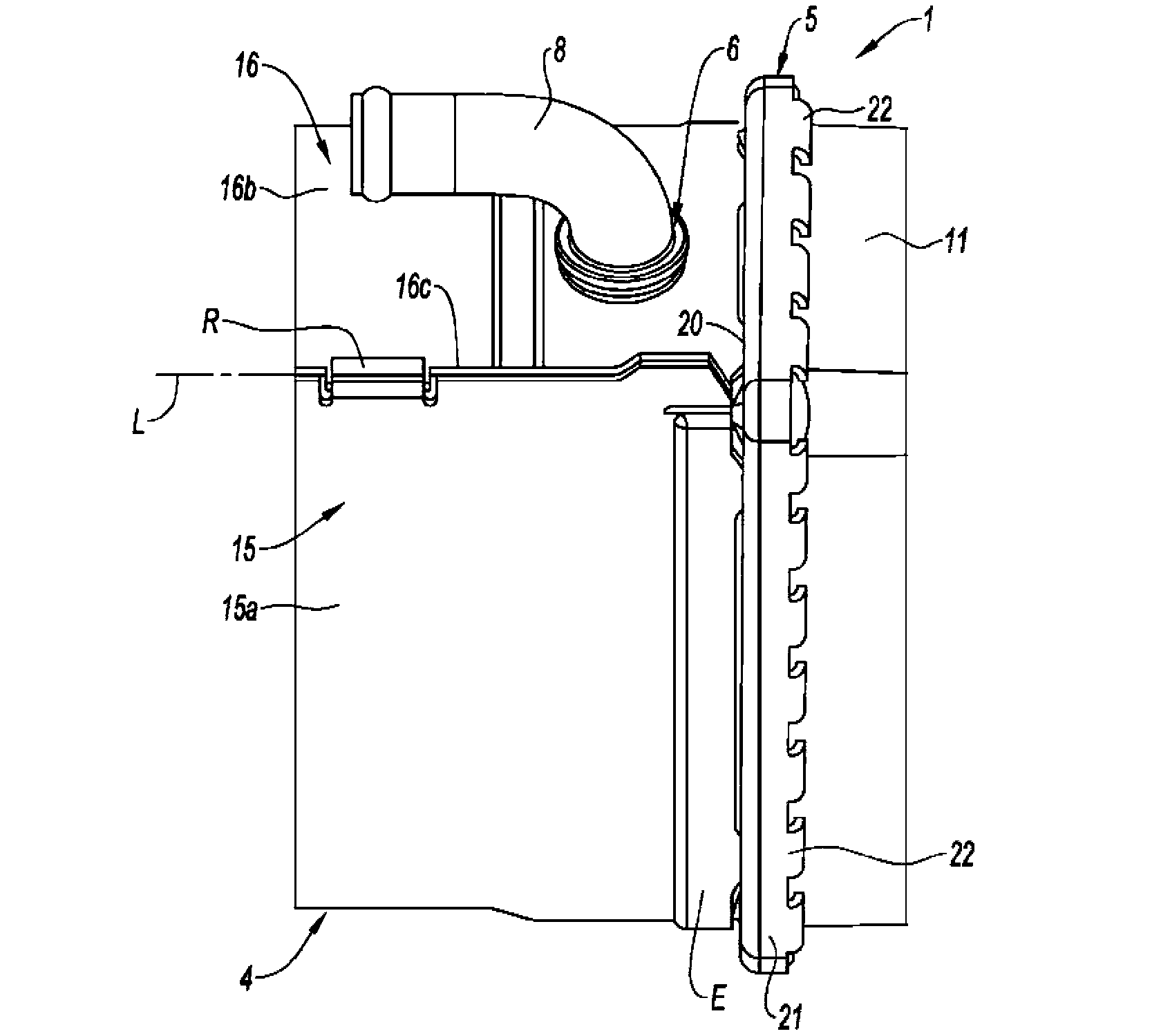

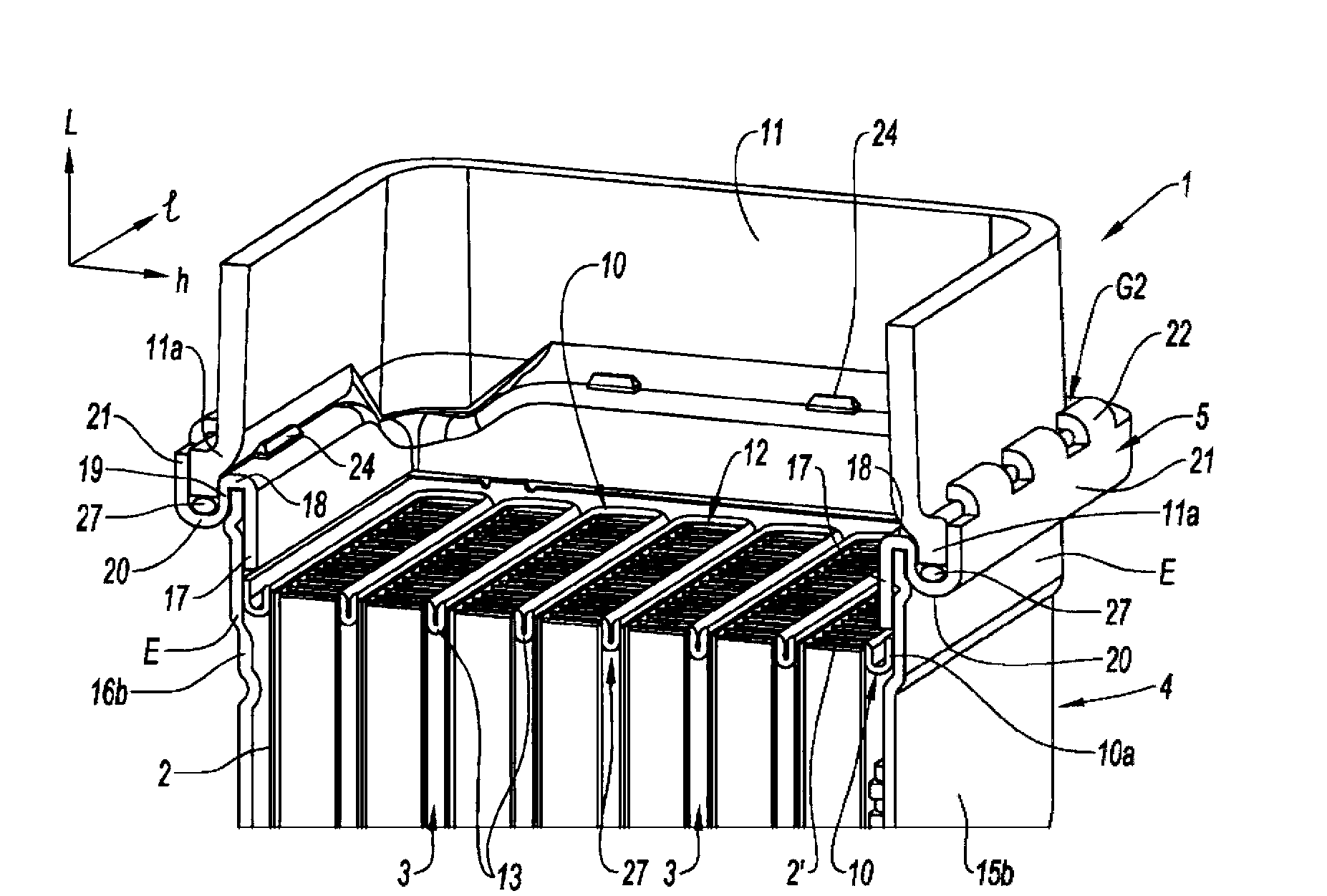

[0043] With reference to the accompanying drawings, and more particularly to Figures 1 to 6, the heat exchanger 1 according to the first embodiment comprises heat exchanging components 2, 2', 3, a housing 4 for receiving or accommodating said components 2, 2', 3, an air inlet collecting box 11 and an air outlet Collection box 11'. The housing 4 comprises openings 6, 7 for connection to pipes 8, 9 for the flow of water, in this particular case an inlet pipe 9 and an outlet pipe 8, said pipes being connected to the water circuit where the exchanger 1 is installed in the water circuit. In the described embodiment, the different parts of the exchanger 1 are brazed to each other, except for the crimped boxes 11, 11'; such exchangers with brazed or crimped exchanger parts are by their usual nature are well known to those skilled in the art.

[0044] Exchanger 1 describes a so-called "air-water" exchanger, ie an exchanger in which the heat-exchanging fluids are air and water. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com