Packing type dust remover

A technology of dust collector and packing type, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc. It can solve the problems of difficult to achieve dust removal effect, damage to desulfurization and denitrification equipment, poor treatment effect, etc., and achieve novel structure , long service life, temperature balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

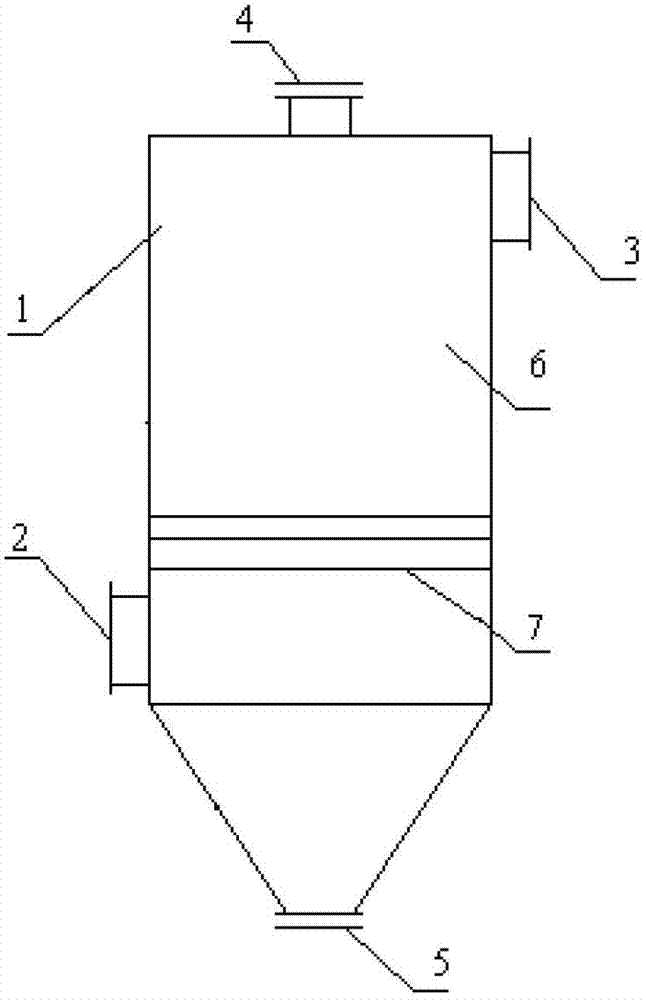

[0028] Such as figure 1 As shown, a packing type dust collector includes a housing 1 with a flue gas inlet 2 and a flue gas outlet 3, a packing inlet 4 is provided on the top of the housing 1, and a packing outlet 5 is provided at the bottom of the housing 1 , a packing area 6 is provided in the housing 1, and an isolation and air-permeable layer 7 is provided below the packing area 6, wherein the smoke inlet 2 and the smoke outlet 3 are arranged on the side wall of the housing 1, and the smoke outlet 3 It is arranged on the upper part of the side wall of the casing 1 , and the smoke inlet 2 is arranged on the lower part of the side wall of the casing 1 and is located below the insulating air-permeable layer 7 .

[0029] In the above embodiment, the isolation air-permeable layer 7 can block the filler so that the filler does not leave the filler area 6. At the same time, it can also make the flue gas pass smoothly into the filler area and contact the filler; Ceramic balls, th...

Embodiment 2

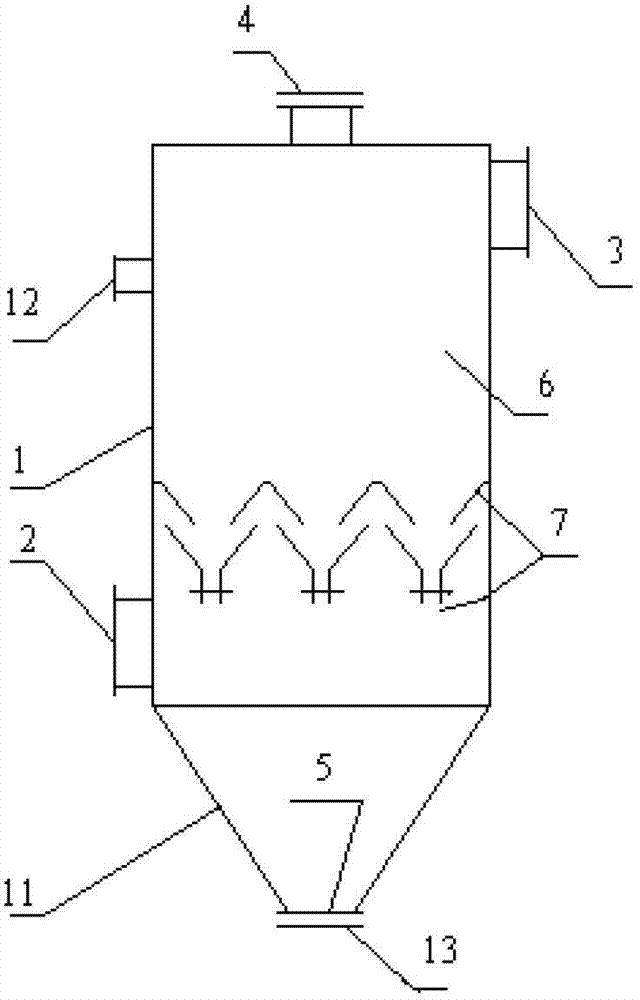

[0032] Such as figure 2 and image 3 Shown, a kind of packed dust collector, its structure and setting are the same as embodiment 1, and difference is:

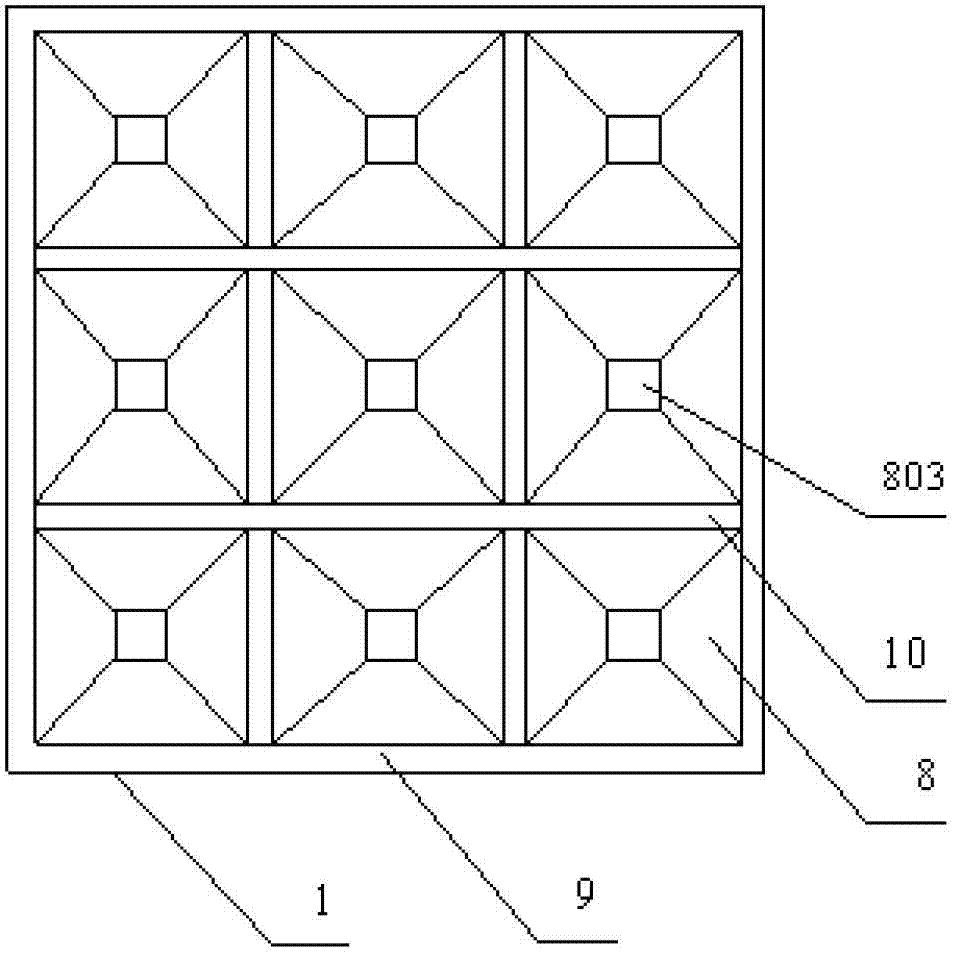

[0033] The isolation air-permeable layer 6 is a double-set bucket layer, and nine double-set buckets 8 are arranged on the double-set bucket layer, and each double-set bucket 8 is connected to each other through a support device; the support device includes an external support frame connected to each other 9 and the inner support beam 10; wherein, the number of double-set buckets 8 vertically arranged on the double-set bucket layer is the same as the number of double-set buckets arranged horizontally, three rows are arranged vertically, three rows are arranged horizontally, and each row There are three, a total of nine;

[0034] Below the isolation air-permeable layer 6 is a discharge hopper 11 connected to the filler outlet 5;

[0035] An observation port 12 is also provided on the side wall of the housing 1;

[0036] A...

Embodiment 3

[0047] Such as figure 2 , image 3 and Figure 4 Shown, a kind of packing dust collector, its structure and setting are the same as embodiment 2, and difference is:

[0048] The diameter of the ceramic balls 14 is 3 mm to 10 mm. After the ceramic balls of this specification are piled up, the smoke and dust can be attached and the gaseous matter can be separated and discharged. At the same time, it is easy to maintain good mechanical properties, which is beneficial to reuse and avoids waste;

[0049] The flue gas inlet 2 and the flue gas outlet 3 are provided with pressure gauges (not shown in the figure), so as to know the pressure difference in the shell in time, and then understand the degree of saturation of the filler in the shell to absorb dust, so that according to the bearing capacity of the shell Depending on the pressure, switch the dust collector or replace the packing in time, so that the dust removal effect can be fully guaranteed.

[0050] The process and prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com