Variable diameter swinging mechanism of spring machine

A technology of a swing mechanism and a spring machine, which is applied to the key parts of the spring machine, can solve the problems of low transmission accuracy and stability, large transmission pressure angle, and large wear of the spring machine, and achieves low sliding rate, small pressure angle, geometric Sliding low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

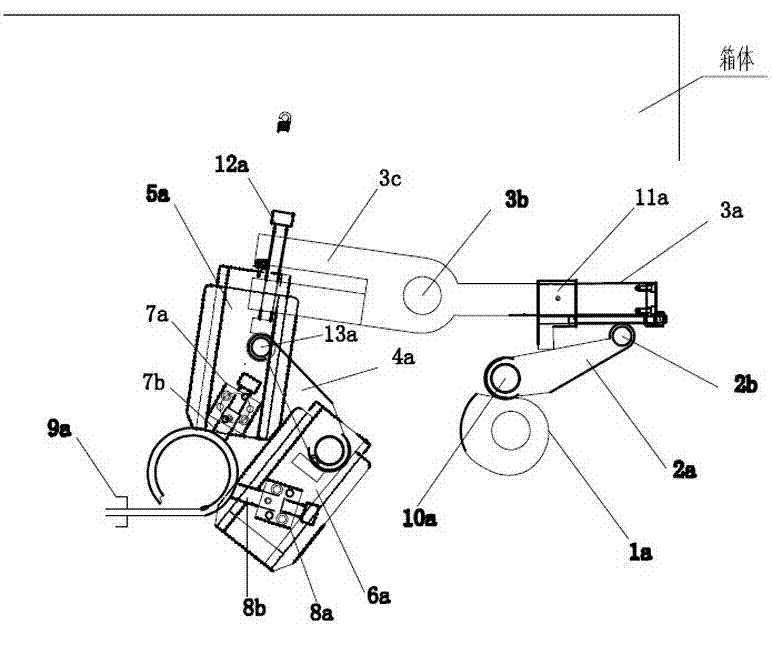

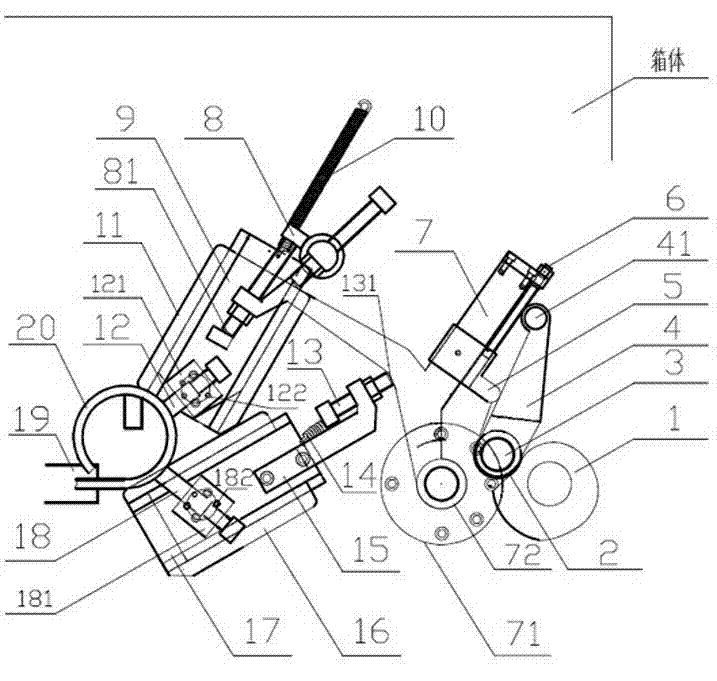

[0024] Such as figure 2 A variable diameter swing mechanism of a spring machine in the present invention comprises a cam 1, a swing rod 4 and a variable diameter lever 7, the variable diameter lever 7 has an inverted "herringbone" shape structure, and the variable diameter lever 7 is installed on a lever pile 71 through a lever sleeve 72, The rolling bearing 2 is in contact with the cam 1, and the rolling bearing 2 is installed on the swing rod 4 through the bearing pin 3. One end of the swing rod 4 is sleeved on the bearing pin 3, and the other end of the swing rod 4 is installed on the swing rod pile 41. The swing rod 4 and the An adjustment block 5 is arranged between the diameter reduction lever 7, and the screw 6 is used to adjust the position of the adjustment block 5 on the diameter reduction lever 7; the end of the diameter reduction lever 7 is equipped with a first bolt 8, and the first bolt 8 is a hexagon socket bolt , the first bolt 8 is in contact with the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com