Flexible cutting machine for sandwich plates

A cutting machine and plate technology, which is applied in metal processing and other directions, can solve the problems of inaccurate cutting length, reduced service life of disc saw blades, and damage to the surface of composite sandwich panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

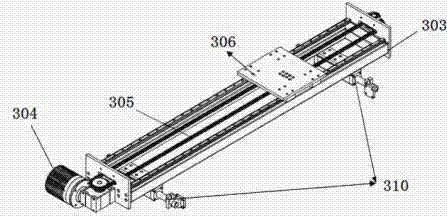

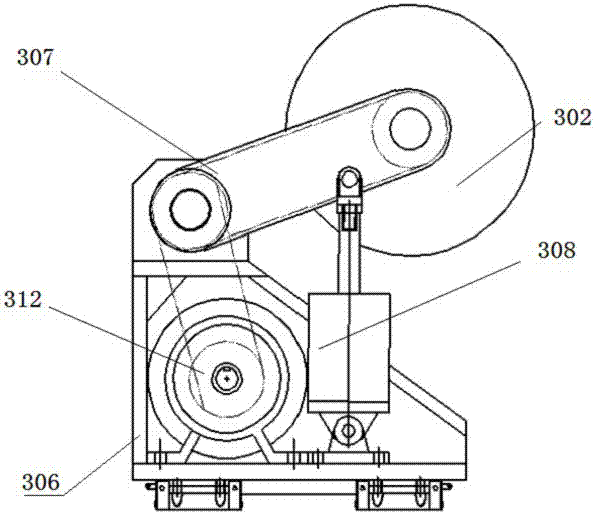

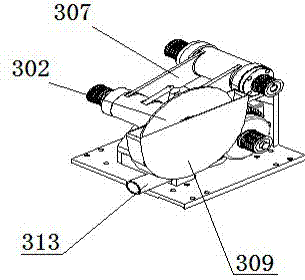

[0019] like Figure 1 to Figure 4 As shown, the flexible cutting machine of a kind of sandwich panel of the present invention comprises the frame 10 of the frame type structure of cuboid, on the frame 10 of two parallel sides of frame 10, all be provided with clamping device 20, frame 10 middle A sandwich panel cutting mechanism and a foam board cutting mechanism are provided. The sandwich panel cutting mechanism is used to cut sandwich panels, such as rock wool boards; the foam board cutting mechanism is used to cut single-layer panels such as foam boards, or to cut composite materials such as no steel strips and EPS core materials. sandwich panel. in:

[0020] The clamping device 20 is a device for clamping the plate to be processed entering the frame 10, which includes a horizontal rubber roller 201 fixed on the frame 10 and two clamping cylinders 202 vertically arranged on the frame 10, The cylinder arms of the two clamping cylinders 202 are connected by a horizontal cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com