Inkjet plastic printing process

An inkjet and process technology, applied in the field of inkjet plastic printing technology, can solve problems such as restricting the use of flatbed printers, and achieve the effects of beautiful colors, realistic effects and high printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

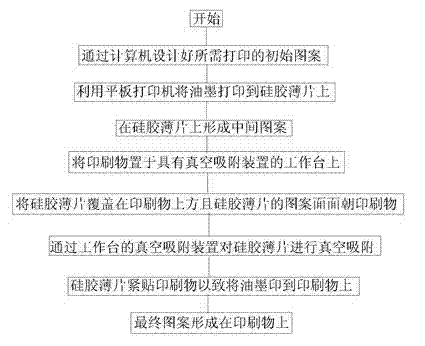

[0014] figure 1 Schematically shows an inkjet plastic printing process according to an embodiment of the present invention.

[0015] The inkjet plastic printing process includes flat printing and plastic printing;

[0016] Flatbed printing, the initial pattern to be printed is designed by the computer and the initial pattern is the mirror image of the final pattern, and the flatbed printer is used to print the ink on the silica gel sheet to form an intermediate pattern on the silica gel sheet. The main components of the inkjet are: 20% resin, 17% pigment, 60% solvent and 3% additive, the thickness of the silica gel sheet does not exceed 1.5mm.

[0017] Plastic printing, place the printed matter on a workbench with a vacuum adsorption device, cover the silicone sheet on the printed matter with the pattern side of the silicone sheet facing the printed matter,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com