Dust-fall treatment system for fluorine gypsum truck loading

A treatment system, fluorogypsum technology, applied in the field of dust suppression devices, can solve problems such as dust flying outside, affecting the health of staff, waste of resources, etc., to achieve the effect of ensuring absorption rate, convenient observation and cleaning, and improving the loading environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

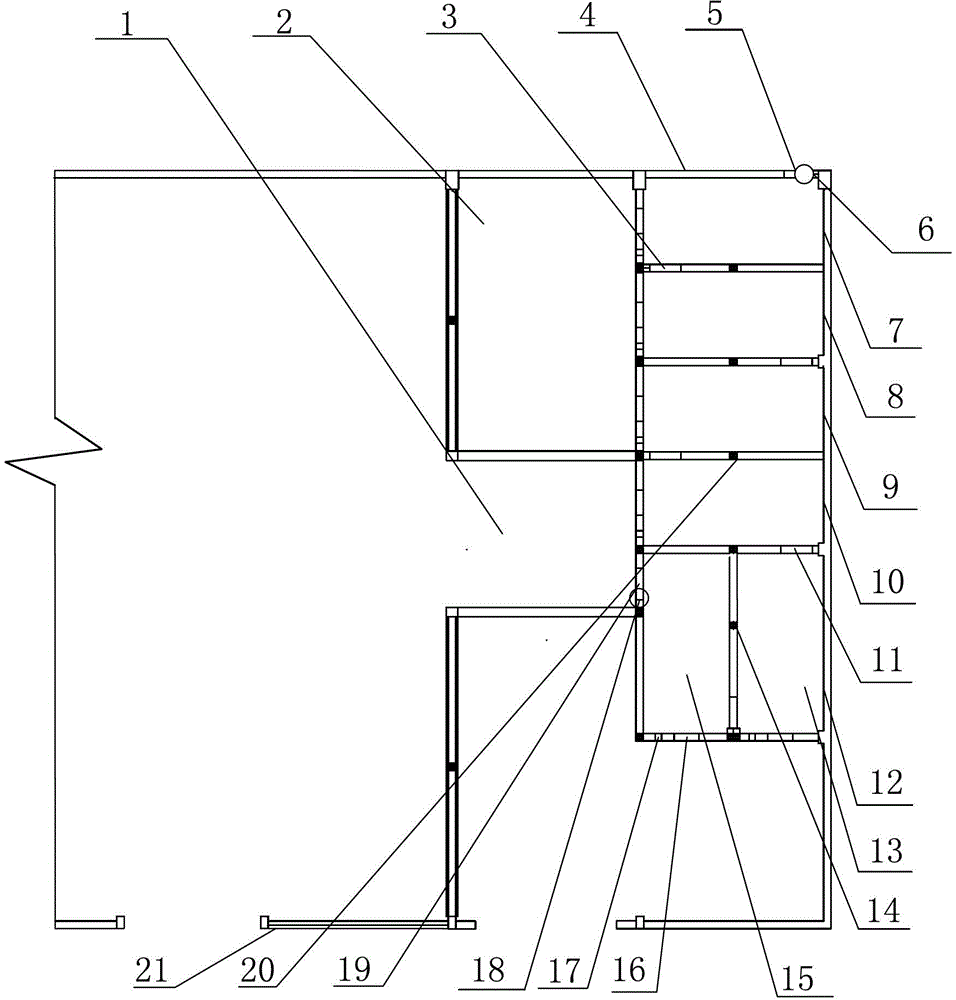

[0010] Such as figure 1 As shown, a dust suppression treatment system for fluorogypsum loading, including a gypsum warehouse 21, a truck parking room 2 and a gravity settling room 4 are arranged in the gypsum warehouse, a loading port 1 is arranged in the middle of the truck parking room 2, and the gravity settling room 4 passes through The dividing plate is divided into the first gravity settling zone 12, the second gravity settling zone 10, the third gravity settling zone 9, the fourth gravity settling zone 8 and the fifth gravity settling zone 7, and the first gravity settling zone 12 passes through the vertical partition 14 is divided into the first main gravity settling area 15 and the first auxiliary gravity settling area 13, the vertical partition 14 between the first main gravity settling area 15 and the first auxiliary gravity settling area 13 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com