Ammonia desulfurization device and process

An ammonia desulfurization and ammonia water tank technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem that the original ammonia desulfurization process cannot meet environmental protection requirements, ammonia escape and aerosol content are high, and it is impossible to achieve ultra-high temperature. Low emission standards and other issues, to achieve the effect of saving operating energy consumption, reducing ammonia escape, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

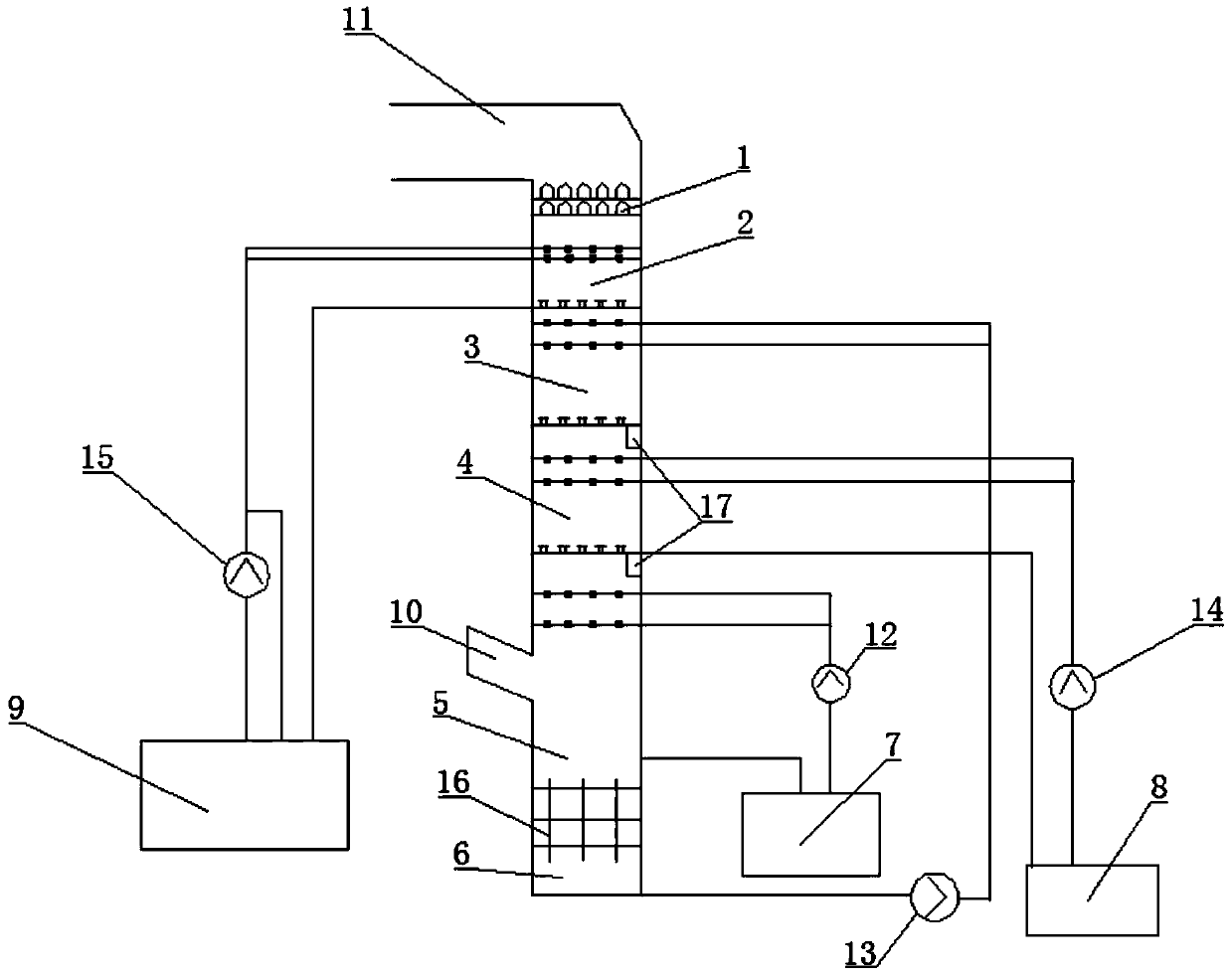

[0020] An ammonia desulfurization device, comprising a demister 1, a washing section 2, a recovery section 3, an absorption section 4, a concentration section 5, an oxidation section 6, a concentration tank 7, an ammonia water tank 8, a washing tank 9, a flue inlet 10, Flue outlet 11, second circulation pump 12, first circulation pump 13, third circulation pump 14, fourth circulation pump 15, oxidation air spray gun 16 and overflow channel 17. The oxidation section 6 is upwardly connected to the concentration section 5, and the concentration section 5 is provided with a flue inlet 10, the concentration section 5 is upwardly connected to the absorption section 4, the absorption section 4 is upwardly connected to the recovery section 3, and the recovery section 3 is upwardly connected to the washing section 2. Section 2 is connected upwards to demister 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com