Forsterite honeycomb body as well as preparation method and application thereof

A forsterite and honeycomb body technology, which is applied in the field of carbon dioxide neutralization methods, can solve the problems of small contact area between materials and CO2, insufficient surface area of solid materials, and reduced production efficiency, etc., to improve surface activity, low raw material cost, and speed up The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

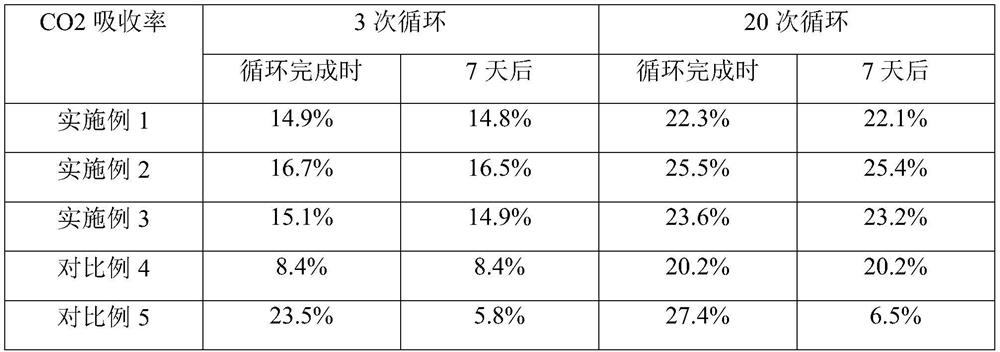

Examples

Embodiment 1

[0029] A kind of forsterite honeycomb body in the present embodiment, comprises following raw material:

[0030] Main ingredients: 90wt% forsterite fine powder, 7wt% adsorbent, 3wt% oil;

[0031] Secondary ingredients: main ingredient 1.5wt% binder A, main ingredient 1wt% additive B.

[0032] In this embodiment, the purity of the forsterite fine powder is MgO36%wt, and the particle size is 200 mesh. The adsorbent is zeolite powder, and the particle size of the adsorbent is 200 mesh. The oil is unsaturated fatty acid glyceride which is liquid at normal temperature. The binding agent A is polyvinylpyrrolidone. The additive B is silica sol.

[0033] The present invention also proposes a method for preparing a forsterite honeycomb body, comprising the steps of:

[0034] (1) Mixing: select raw materials according to the ratio, add 10% water of the total mass of raw materials, put them into the mud mixer for mixing, knead and make mud suitable for molding, store it for 18 hours...

Embodiment 2

[0039] A kind of forsterite honeycomb body in the present embodiment, comprises following raw material:

[0040] Main ingredients: 90wt% forsterite fine powder, 9wt% adsorbent, 1wt% grease;

[0041] Secondary ingredients: main ingredient 2.5wt% binder A, main ingredient 2wt% additive B.

[0042] In this embodiment, the purity of the forsterite fine powder is MgO38%wt, and the particle size is 180 mesh. The adsorbent is activated carbon powder, and the particle size of the adsorbent is 180 mesh. The oil is unsaturated fatty acid glyceride which is liquid at normal temperature. The binding agent A is polyvinylpyrrolidone. The additive B is water glass.

[0043] The present invention also proposes a method for preparing a forsterite honeycomb body, comprising the steps of:

[0044] (1) Mixing: select raw materials according to the ratio, add water with 11% of the total mass of the raw materials, put them into the mud mixer for mixing, knead and make mud suitable for molding,...

Embodiment 3

[0049] A kind of forsterite honeycomb body in the present embodiment, comprises following raw material:

[0050] Main ingredients: forsterite fine powder 92wt%, adsorbent 5wt%, grease 3wt%;

[0051] Secondary ingredients: main ingredient 3.5wt% binder A, main ingredient 2.5wt% additive B.

[0052] In this embodiment, the purity of the forsterite fine powder is MgO40%wt, and the particle size is 160 mesh. The adsorbent is activated carbon powder, and the particle size of the adsorbent is 160 mesh. The oil is unsaturated fatty acid glyceride which is liquid at normal temperature. The binding agent A is polyvinylpyrrolidone. The additive B is silica sol.

[0053] The present invention also proposes a method for preparing a forsterite honeycomb body, comprising the steps of:

[0054] (1) Mixing: select raw materials according to the ratio, add water with 12% of the total mass of raw materials, put them into the mud mixer for mixing, and make mud suitable for molding, store it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com