Air-extrusion type oil transporting and refueling bag

A squeeze-type, air-based technology, applied in the direction of transportation and packaging, rigid containers, special distribution devices, etc., can solve the problem of single oil output method, achieve the effect of convenient oil supply and improve field adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

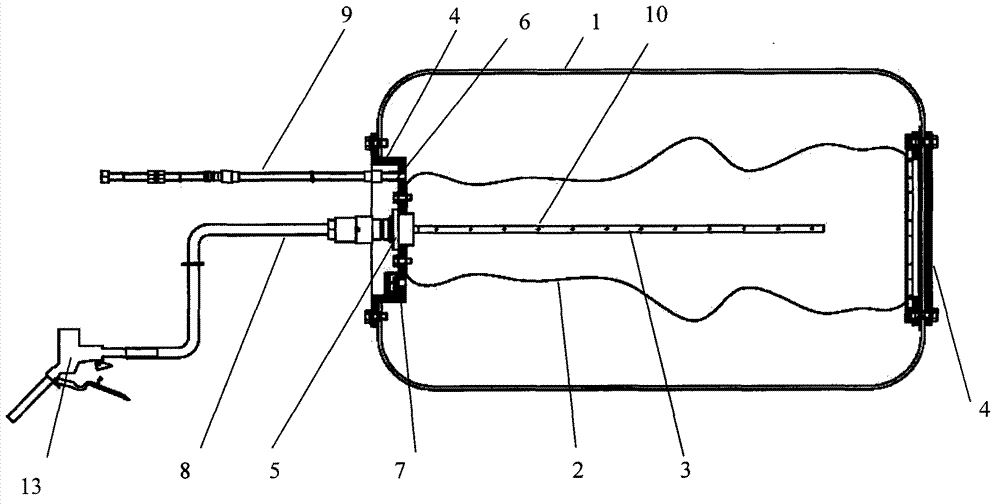

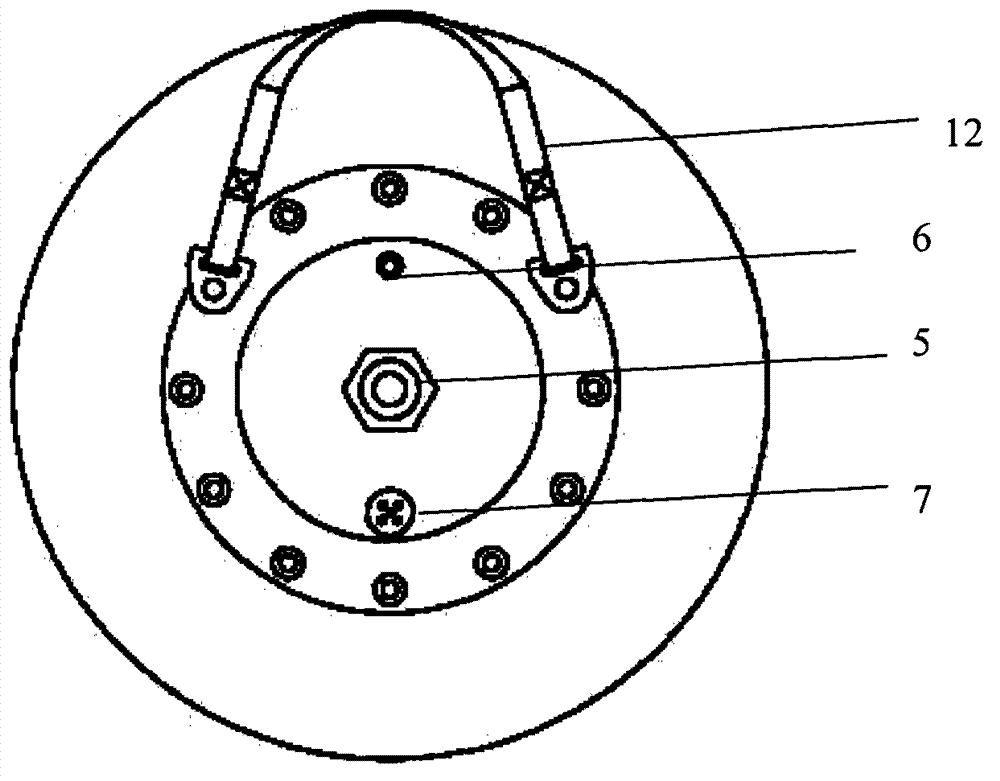

[0046] Such as figure 1 (Schematic diagram of the structure of the transport oil bag of the present invention), the air extrusion type transport oil bag of the present embodiment includes an outer bag 1, an inner bag 2, an oil guide pipe 3, a flange 4, an oil inlet and outlet valve 5 and an inflation valve 6; The outer bag 1 is a cylindrical structure with an open end, and its toughness and hardness are higher than the inner bag 2; the inner bag 2 is a bag-like structure with an open end and is arranged inside the outer bag 1 The direction of the opening end of the inner bag 2 is the same as the direction of the opening end of the outer bag 1, and the two ends of the inner bag 2 are respectively connected to the two ends of the outer bag 1 through the flange 4, so that the inner bag 2 and the outer bag 1 A closed cavity is formed between them; the oil inlet and outlet valve 5 and the inflation valve 6 are all arranged on the flange 4 at the open end, wherein the oil inlet and ...

Embodiment 2

[0057] Such as figure 1 (Schematic diagram of the structure of the transport oil bag of the present invention), the installation method of the air extrusion type transport oil bag of the present embodiment includes:

[0058] 1. Set an open end of the outer bag 1 to make it a flexible cylindrical structure;

[0059] 2. Set an open end of the inner bag 2 to make it a bag-like structure;

[0060] 3. Set the inner bag 2 inside the outer bag 1 so that the direction of the opening end of the inner bag 2 is the same as the direction of the opening end of the outer bag 1, and connect the two ends of the inner bag 2 to the outer bag by means of the flange 4 respectively. The two ends of 1 are connected so that a closed cavity is formed between the inner capsule 2 and the outer capsule 1;

[0061] 4. Install an oil inlet and outlet valve 5 and an air charging valve 6 on the flange 4 at the opening end, so that the oil inlet and outlet valve 5 communicates with the inner bag 2, and mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com