Balcony guardrail

A technology for guardrails and balconies, which is applied to building structures, stepped structures, buildings, etc., can solve problems such as corrosion and easy rust of balcony guardrails, and achieve the effects of prolonging service life, low production cost, good toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

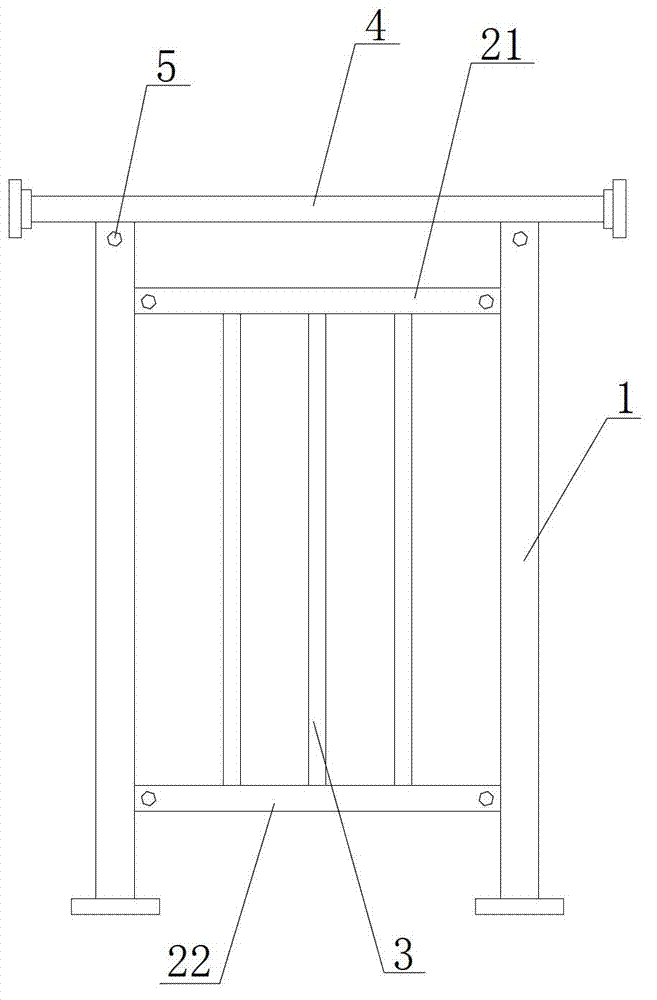

[0018] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the balcony guardrail of the present invention. This guardrail is mainly installed on the balcony, which can not only play a certain role in safety protection, but also has a beautiful and elegant appearance and has a good ornamental value.

[0019] The balcony guardrail of this embodiment includes two uprights 1, and a plurality of crossbeams are fixed between two uprights 1, and the situation of two crossbeams shown in the figure is respectively upper crossbeam 21 and lower crossbeam 22, and upright 1 Be fixed by the following method with upper beam 21, lower beam 22:

[0020] On the inner walls of the ends of the upper cross beam 21 and the lower cross beam 22, detachable intermediate connectors (not shown in the figure) are respectively fixed, and the intermediate connectors are detachably fixed to the column 1 at the same time, here through bolts 5 The intermediate connectors are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com