Backlight module and display device

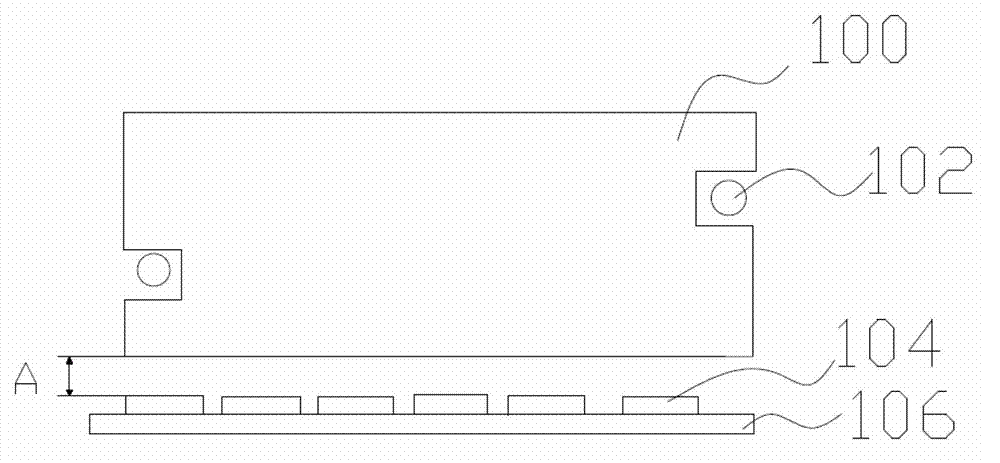

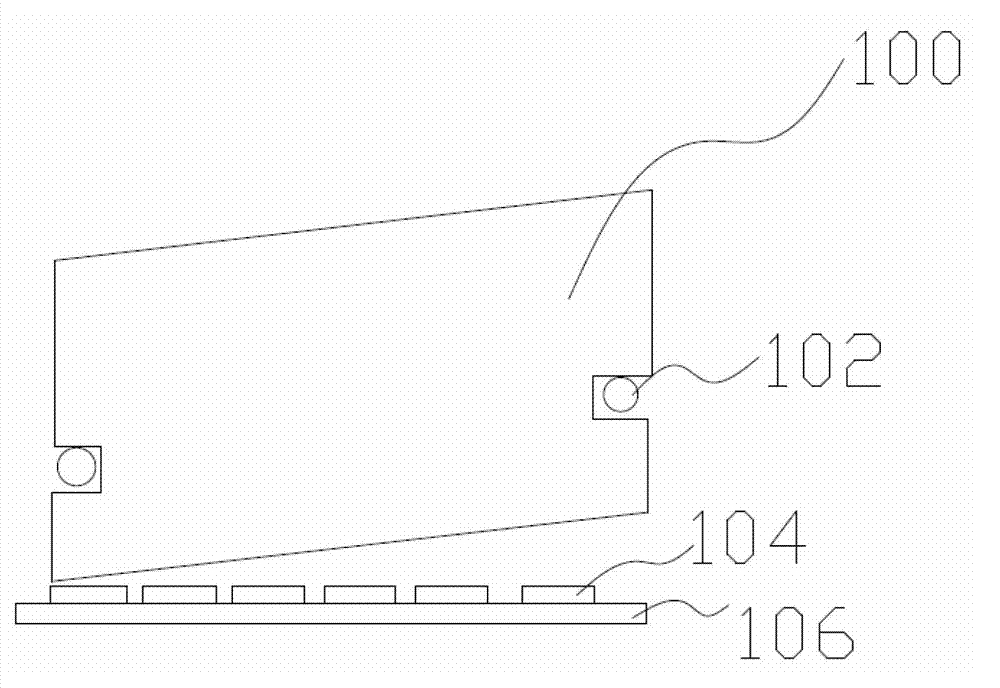

A technology for a backlight module and an adjustment device, which is applied to identification devices, lighting devices, fixed lighting devices, etc., can solve the problems of inconsistent spacing, collision, damage to the light guide plate 100 and the LED 104, etc., and achieve the effect of preventing optical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

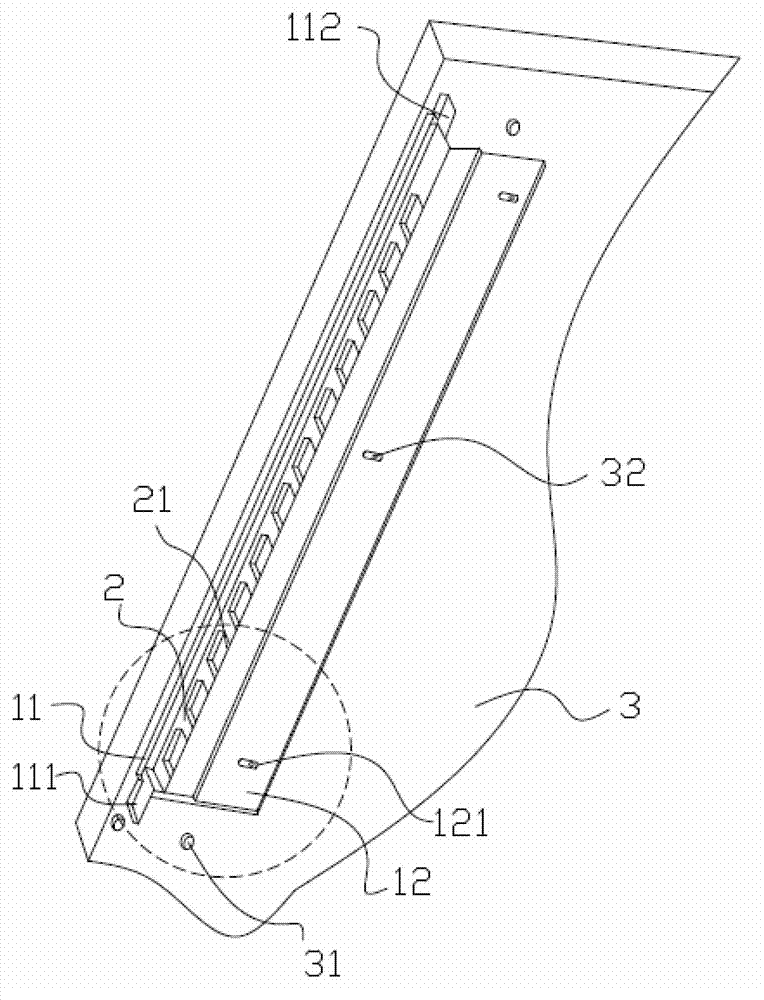

[0028] Such as figure 2 Shown is a schematic diagram of a part of the structure of the backlight module of the present invention. Figure 2a for figure 2 The enlarged schematic diagram of the middle part. The backlight module includes a backplane 3, a first heat dissipation plate 11 and a light source 21, the first heat dissipation plate 11 is arranged on the backplane 3, the first heat dissipation plate 11 has fixing parts 111, 112; the light source 21 is arranged on the on the first cooling plate 11. Such as image 3 Shown is a schematic diagram of the structure of the first compartment of the backlight module of the present invention. The backlight module further includes a light guide plate 7 disposed on one side of the light source 21 , and there is a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com