Garbage incinerator body with high heat-insulating performance

A waste incinerator, performance technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of poor heat insulation performance, and achieve the effect of good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

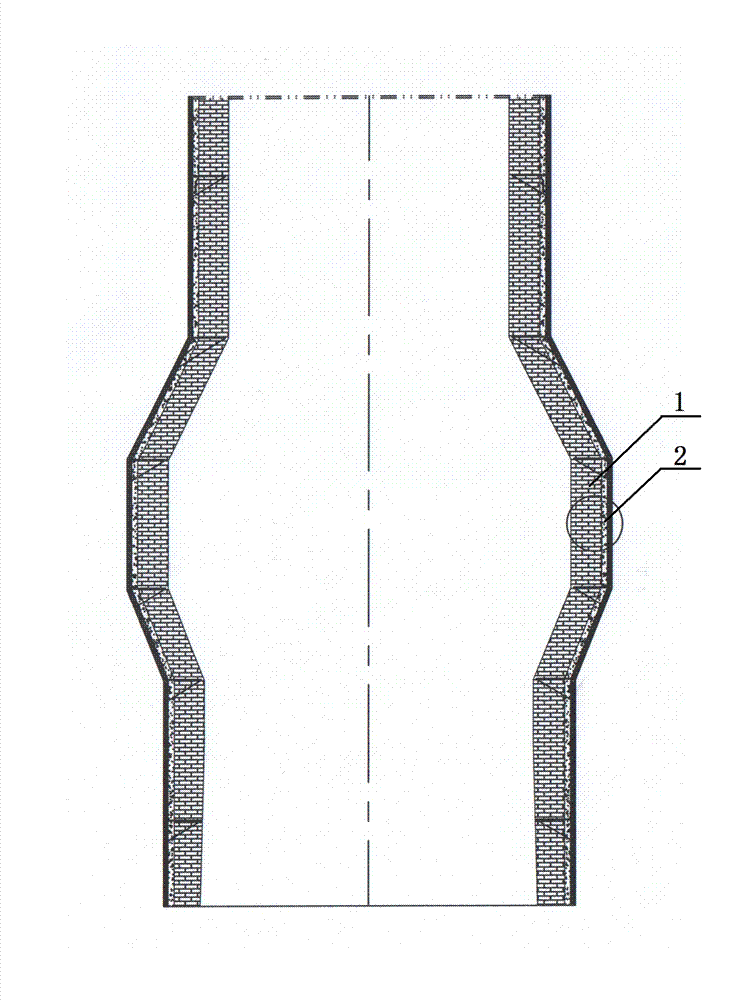

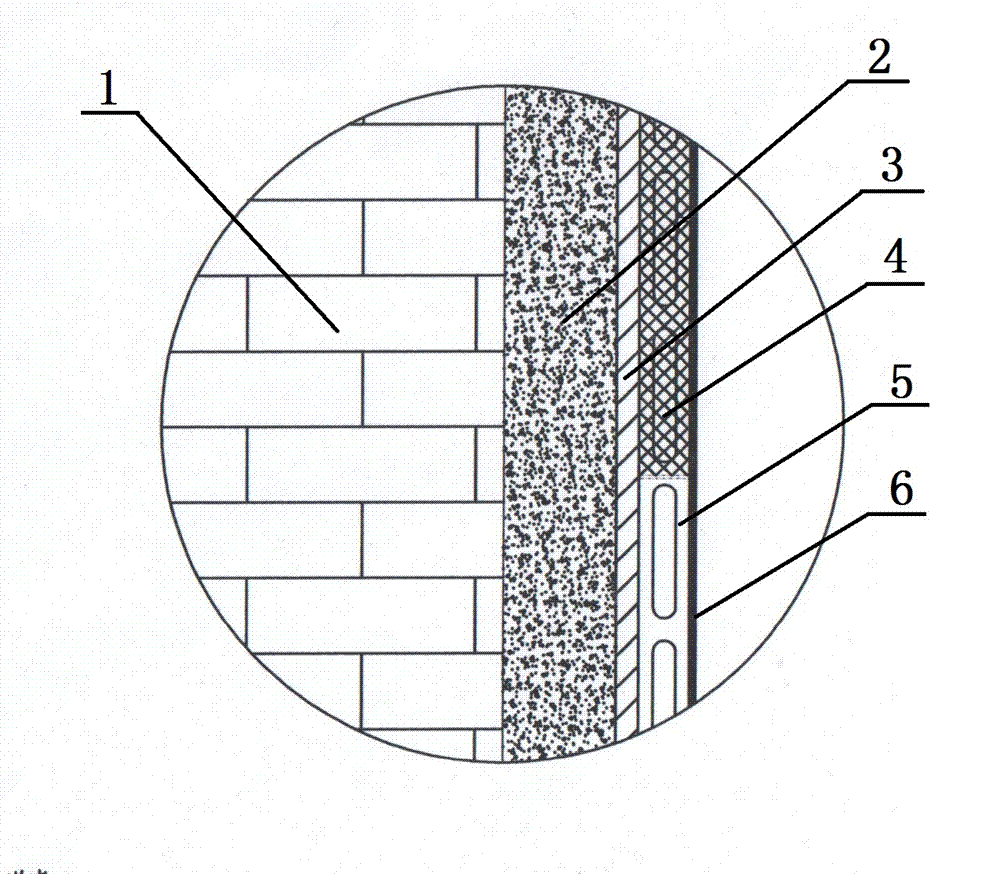

[0010] Such as figure 1 with figure 2 As shown, the body of the garbage incinerator with high heat insulation performance of the present invention includes a body, which is cylindrical and arranged vertically. The body is composed of a metal shell 3 and a refractory brick layer 1 inside the metal shell. The metal shell There is high temperature resistant filler 2 between 3 and refractory brick layer 1. The middle part of the body protrudes outward along the circumferential direction, so that the cross section of the inner chamber in the middle part of the body is larger than the upper and lower parts. The outer side of the metal shell 3 has thermal insulation cotton 4, and the outer side of the thermal insulation cotton 4 is a color steel plate 6. There are punched angle steels 5 between the color steel plate 6 and the metal shell 3, and the punched angle steels 5 are evenly arranged along the circumferential direction. The inner side and the outer side of the punched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com