Waterborne fluorocarbon heat insulation paint having heat insulation effect and preparation method thereof

A water-based fluorocarbon, heat-insulating coating technology, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve the problems of poor corrosion resistance, poor heat insulation effect, etc., and achieve excellent weather resistance, high electronegativity, The effect of strong carbon-fluorine bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

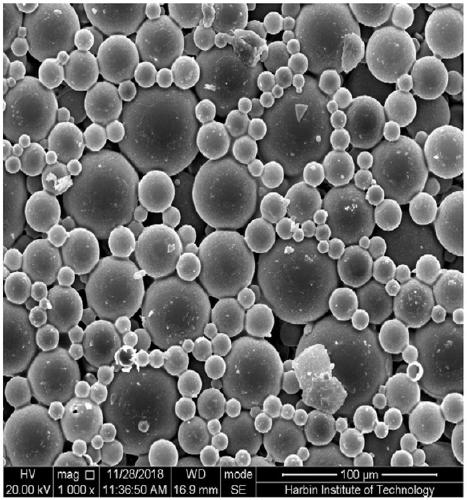

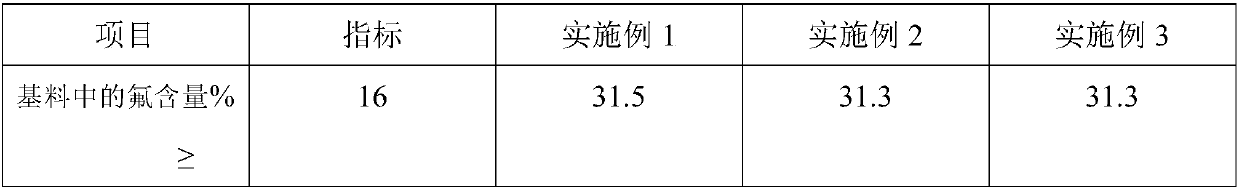

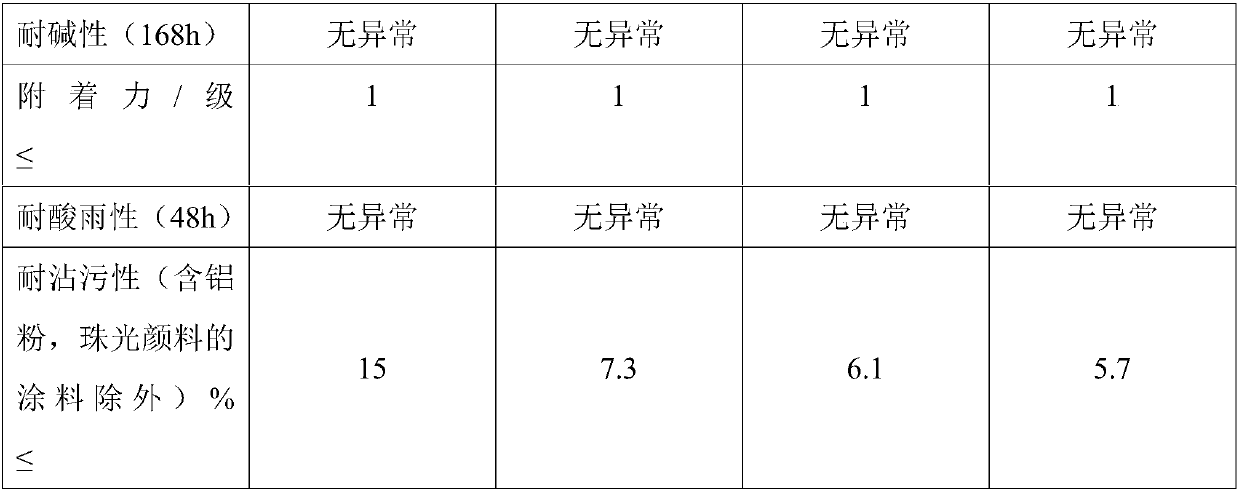

[0028] Specific Embodiment 1: In this embodiment, a water-based fluorocarbon heat-insulating coating with heat-insulating effect consists of 18-26 parts by mass of deionized water, 50-60 parts of fluorocarbon emulsion, 1-5 parts of dispersant, 0.1-0.5 parts of pH regulator, 0.01-0.2 parts of defoamer, 1-5 parts of emulsifier, 0.1-1 part of thickener, 1-3 parts of pigment and filler, 8-12 parts of glass microspheres, 2-2 parts of organic solvent 5 parts and 3 to 5 parts of film-forming aids.

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that: the organic solvent is one or a combination of propylene glycol, dimethyl phthalate, dipropylene glycol butyl ether and ethylenediamine. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the pigment and filler are one or more of zeolite, bentonite, heavy calcium and titanium dioxide. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com