Cooling device in high-vacuum distillation system

A distillation system and cooling device technology, applied in vacuum distillation, steam/vapor condensers, lighting and heating equipment, etc., can solve problems such as hindering machine operation, damaging pump body, polluting the environment, etc., to reduce product volume and reduce cleaning Frequency, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

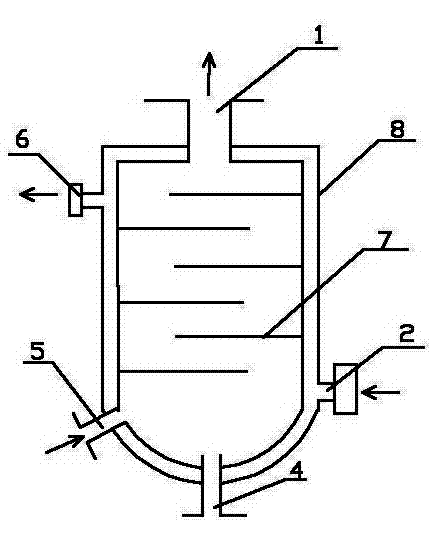

[0012] Embodiment 1, a cooling device in a high vacuum distillation system, with reference to figure 1 , the housing 8 is a double-layer hollow housing, the lower part of the hollow housing 8 is provided with a water inlet 2, and the upper part is provided with a water outlet 6, and the middle cavity between the water inlet 2 and the water outlet 6 and the hollow housing 8 Connected, the top of the housing 8 is provided with an air outlet 1, and the lower part is provided with an air inlet 5, the air inlet 5 and the air outlet 1 communicate with the inner cavity of the housing 8, and the upper part of the inner cavity of the housing 8 is provided with a gas baffle 7. The bottom of the casing 8 is provided with a discharge port 4 communicating with the inner cavity of the casing, which constitutes a structure of the present invention.

Embodiment 2

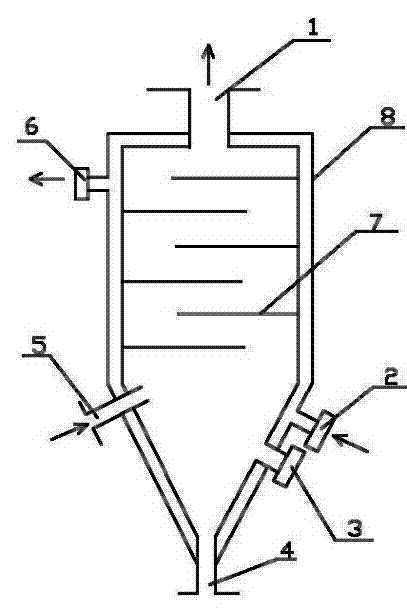

[0013] Embodiment 2, a cooling device in a high vacuum distillation system, with reference to figure 2 , on the basis of Embodiment 1, the upper part of the housing 8 is cylindrical, the lower part is conical, the discharge port 4 is arranged at the tip of the conical housing 8, and the lower part of the housing 8 is provided with an observable housing The inner sight mirror 3, the openings between the adjacent gas baffles 7 and the inner wall of the housing 8 are arranged in a staggered manner, and the others are completely the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com