Halogen-free flame-retardant plastic weaving material and preparation method thereof

A plastic woven bag and feeding section technology, applied in the field of halogen-free flame-retardant plastic woven materials and its preparation, can solve the problems of less application of plastic woven bags and harsh drawing processing of plastic woven materials, so as to achieve easy operation and overcome the mechanical properties of plastics Decrease, the effect of good flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

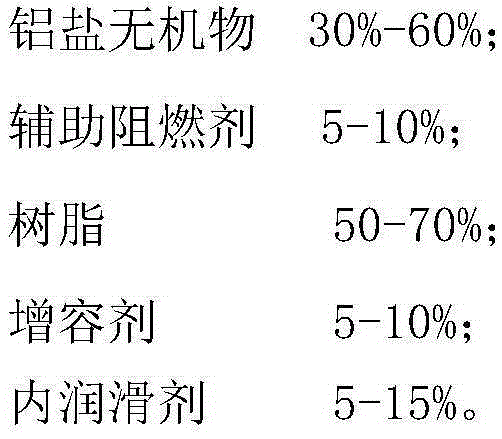

[0011] Take 50 kg of nano-scale aluminum hydroxide, 50 kg of polyethylene resin, 10 kg of modified zinc borate, 15 kg of polyethylene maleic anhydride modified masterbatch, and 5 kg of paraffin, mix them in a high-mixer, and then extrude them in a twin-screw Granulate in the machine, control the temperature of the feeding section to 70°C and the temperature of the metering section to 130°C; after granulation, the halogen-free flame-retardant plastic woven material of the present invention can be obtained.

[0012] Table 1

[0013] Test items

Embodiment 2

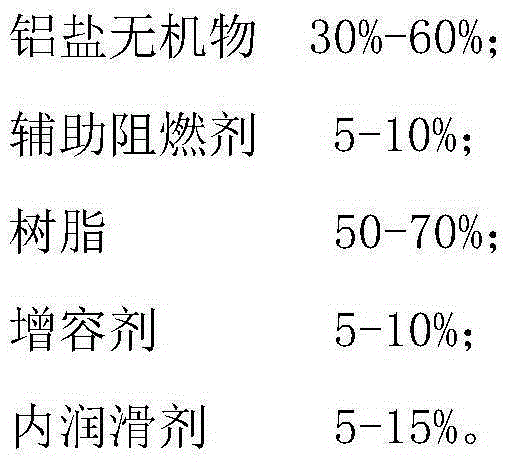

[0015] Take 60 kg of nano-level aluminum hydroxide, 50 kg of polyethylene resin, 10 kg of modified zinc borate, 2 kg of silane coupling agent, and 5 kg of paraffin, mix them in a high-mixer, and then granulate them in a twin-screw extruder The temperature of the feeding section is controlled at 90°C and the temperature of the metering section is 170°C; the halogen-free flame-retardant plastic braided material of the present invention can be obtained after granulation.

[0016] Table 2

[0017] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com