Environment-friendly antibacterial latex paint and preparation method thereof

A latex paint, environmentally friendly technology, applied in the field of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

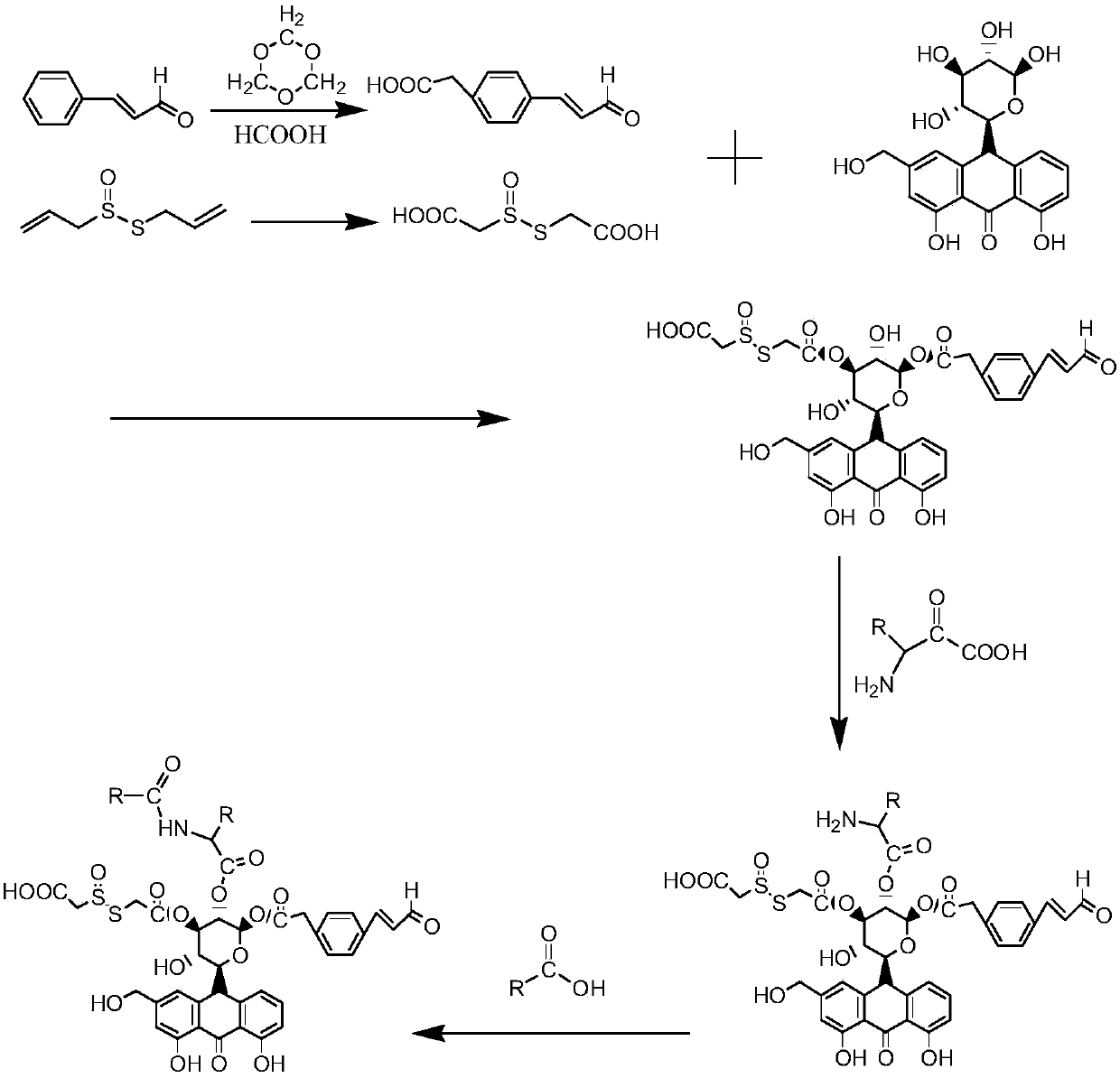

[0026] Prepare a kind of method for environment-friendly antibacterial latex paint, concrete preparation steps are as follows:

[0027] Step 1, cinnamaldehyde modification: take 1.5g cinnamaldehyde and 1 g paraformaldehyde dissolved in 100 ml absolute ethanol, adjust the pH to 2 with HCl, raise the temperature to 70°C, add 2.3 g anhydrous zinc chloride, stir (320r / min) After 4 hours, add 2.5 g of formic acid and 1.2 g of aluminum trichloride, and continue the reaction for 2.5 hours. The reaction solution was extracted four times with diethyl ether, the organic phases were combined, dried with 4.8 g of anhydrous sodium sulfate, filtered, spin-dried with diethyl ether, and vacuum-dried at 80°C for 8 h to obtain the target product, ie, acetoxycinnamaldehyde.

[0028] Step 2, allicin modification: 4.2 g KMnO 4 Dissolve it in 200 ml of water, add it to a 500 ml three-neck flask, adjust the pH of the solution to 2 with HCl, add 3.5 g of allicin while stirring (240 - 380 r / min) (0.5...

Embodiment 2

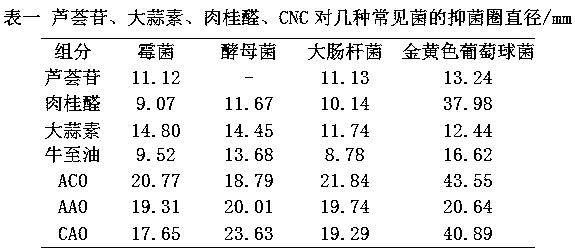

[0032] Table 1 and Table 2 are the antibacterial performance indexes of the macromolecular antibacterial agent synthesized by the present invention and each component. The detection of the inhibition zone is determined by agar diffusion test, and the minimum antibacterial concentration (MIC) is determined by the double dilution method.

[0033]

[0034] (Note: The concentration of each antibacterial substance used to test the diameter of the inhibition zone in Table 1 is 0.5g / ml, "-" means no obvious effect, CNC is a combination of aloin, cinnamaldehyde and allicin antibacterial macromolecules; ACO is aloe vera glucoside, cinnamaldehyde and oregano oil; AAO is a combination of aloin, allicin and oregano oil; CAO is a combination of cinnamaldehyde, allicin and oregano oil).

[0035]

[0036](Note: "-" in Table 2 means no obvious effect; CNC is a combination of aloin, cinnamaldehyde and allicin antibacterial macromolecule; ACO is a combination of aloin, cinnamaldehyde and o...

Embodiment 3

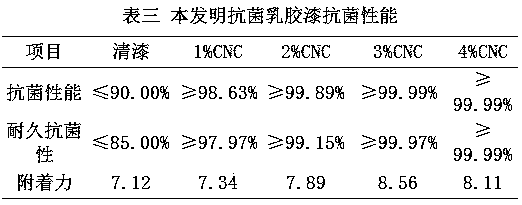

[0041] Example 3. Comparison of antibacterial effects of different latex paints.

[0042] The prepared antibacterial latex paint of comparative example 1 and the antibacterial performance of common antibacterial paint, concrete results are shown in the following table:

[0043]

[0044] (Note: The organic quaternary ammonium salt antibacterial coating in Table 4 is the coating prepared by adding 3% quaternary ammonium salt antibacterial agent; inorganic Ag + Antibacterial coating is added with 3%Ag + coatings prepared with antimicrobial agents)

[0045] It can be seen from Table 4 that the CNC environmental protection antibacterial coating is superior to other coatings in terms of antibacterial performance and durable antibacterial performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com