Contact-type cylinder diameter measurement device

A diameter measurement and measurement device technology, applied in the field of measurement, can solve the problems of high hardware requirements and high manufacturing costs, and achieve the effect of ensuring close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings:

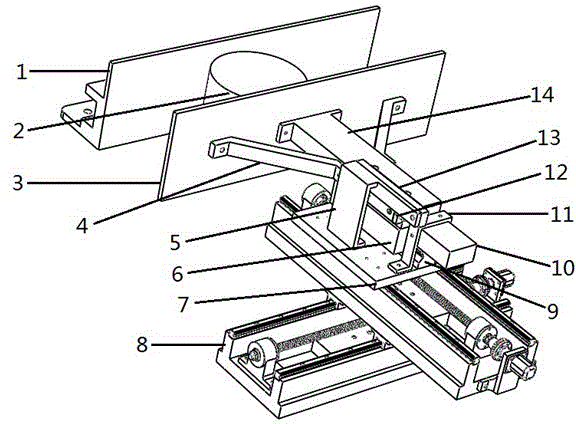

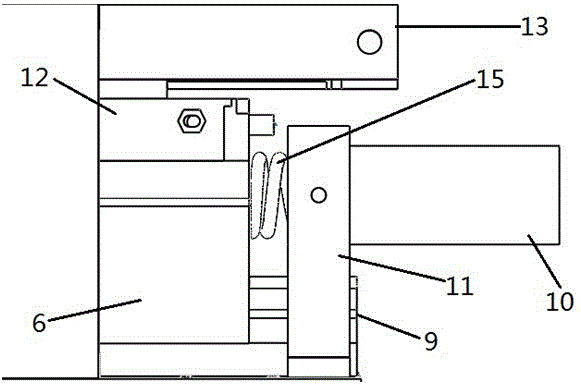

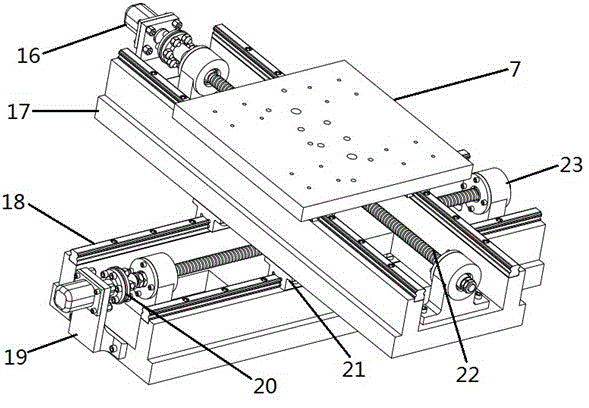

[0018] Such as figure 1 , figure 2 , image 3 As shown, a contact type cylinder diameter measuring device consists of XY table 8, upper table 7, dovetail guide 9, linear slide 6, main bracket 14, side bracket 4, movable baffle 3, static baffle 1. The connecting frame 5, the spring 15, the spring tailstock 10, the fixed support 11, the grating ruler main scale 13 and the grating scale reading head 12 are composed; the XY table is composed of the base 17, the guide rail 18, the sliding seat 21, the lead screw 22, and the bearing The base 23, the coupling 20, the fixed frame 19, and the motor 16 are composed of two CNC worktables in the X direction and the Y direction. Its working principle is that the motor is driven by a lead screw to drive the worktable to move in X and Y directions.

[0019] See figure 1 with figure 2 , The brackets 4 on both sides are equal in size and symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com