Pulse power source based on LTD (Laser Target Designator) self-synchronizing switch

A technology of pulse power source and self-synchronization, applied in the field of pulse power, can solve the problem of difficult synchronization of LTD multi-switches, and achieve the effect of simple and reliable synchronization process, low energy loss, and reliable high-voltage pulse output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

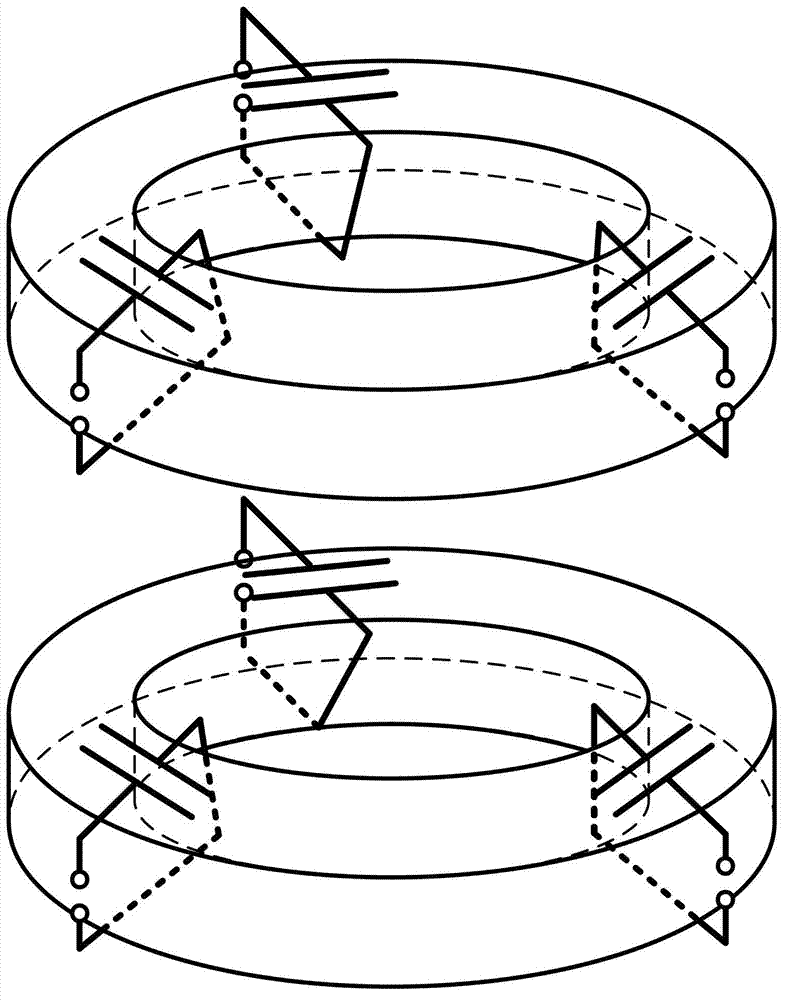

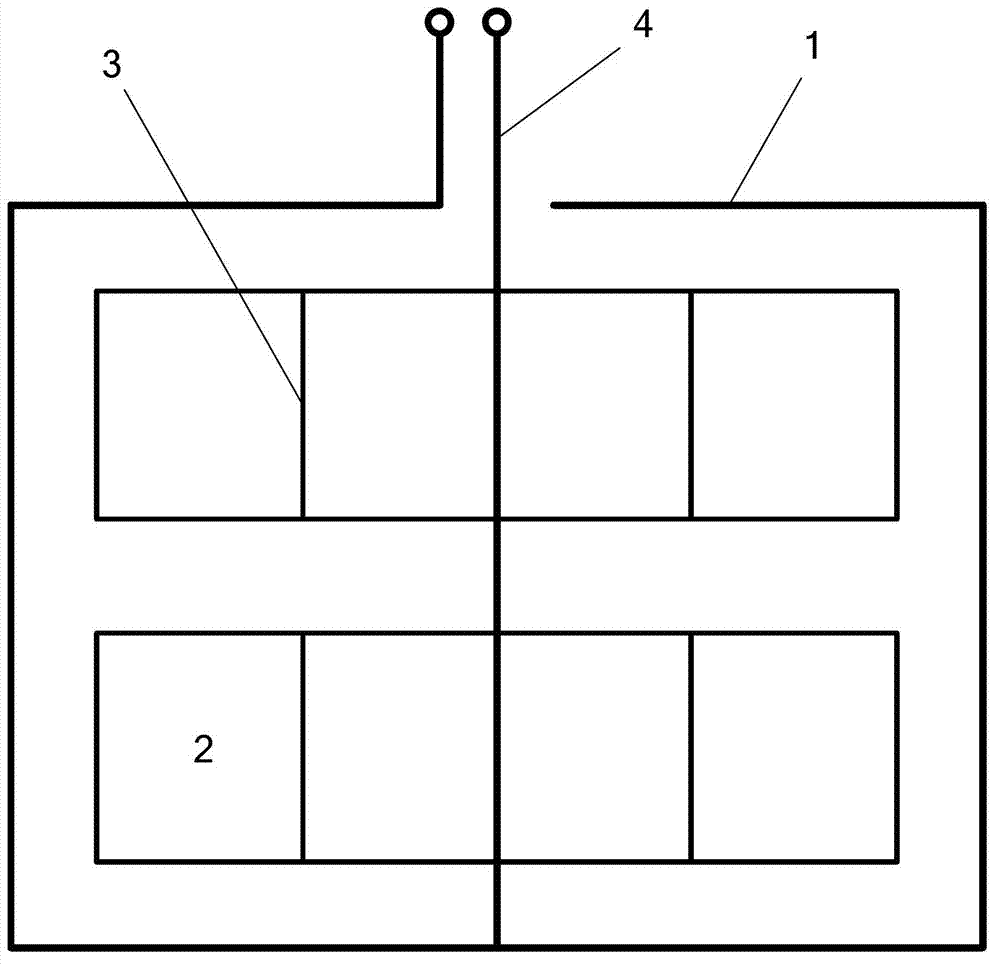

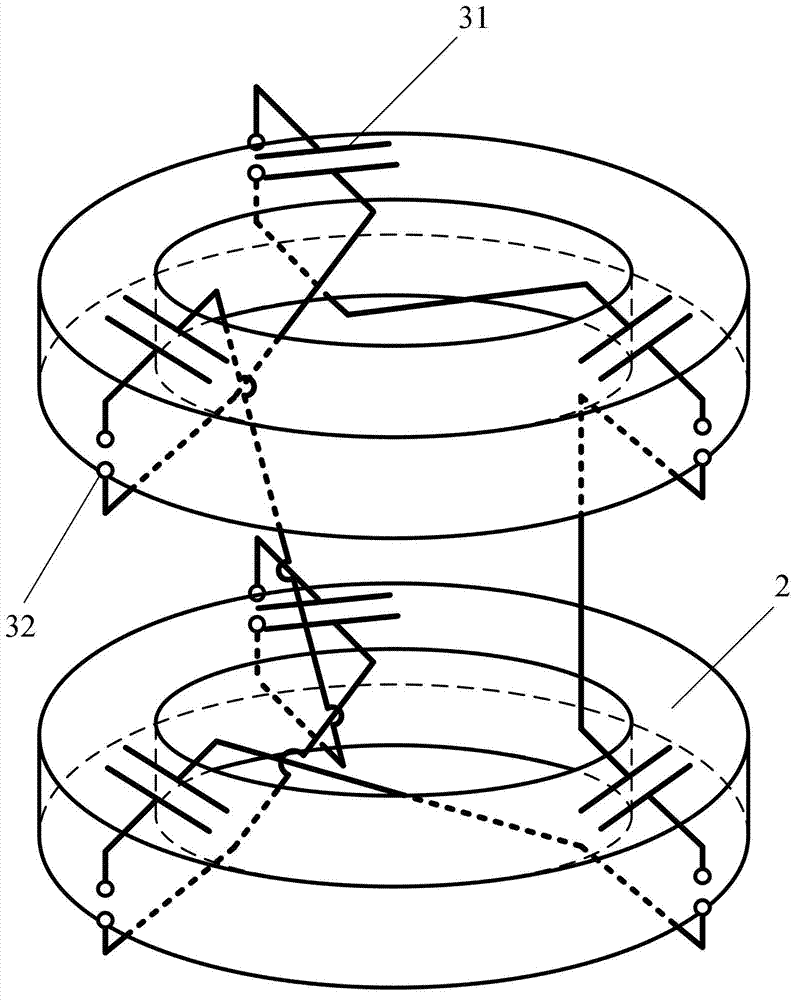

[0025] like figure 2 and Figure 4 As shown, a pulse power source based on an LTD self-synchronous switch, including an outer conductor; the outer conductor includes a conductor box 1 and a conductor bar 4, and the conductor box 1 is provided with two magnetic rings 2, and the two magnetic rings 2 are stacked concentrically Arranged and there is a gap between the two magnetic rings 2 ; the conductor bar 4 is vertically arranged at the bottom of the conductor box 1 and extends out of the conductor box 1 after penetrating the two magnetic rings 2 .

[0026] In this embodiment, the magnetic ring 2 is a ferrite magnetic ring; the conductor box 1 is a hollow metal cylinder, and the top of the cylinder is provided with a through hole for the conductor bar 4 to protrude; the conductor bar 4 extends out of one end of the conductor box 1 It is connected to one end of the resistive load 6 , and the other end of the resistive load 6 is connected to any point on the edge of the through ...

Embodiment 2

[0032] like figure 2 and Figure 5 As shown, a pulse power source based on an LTD self-synchronous switch, including an outer conductor; the outer conductor includes a conductor box 1 and a conductor bar 4, and the conductor box 1 is provided with two magnetic rings 2, and the two magnetic rings 2 are stacked concentrically Arranged and there is a gap between the two magnetic rings 2 ; the conductor bar 4 is vertically arranged at the bottom of the conductor box 1 and extends out of the conductor box 1 after penetrating the two magnetic rings 2 .

[0033] In this embodiment, the magnetic ring 2 is an amorphous magnetic ring; the conductor box 1 is a hollow metal cylinder, and the top of the cylinder is provided with a through hole for the conductor rod 4 to protrude; The load 6 is connected, and one end extending from the conductor box 1 is connected to one end of the inner layer conductor of the variable impedance line 5, the other end of the inner layer conductor of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com