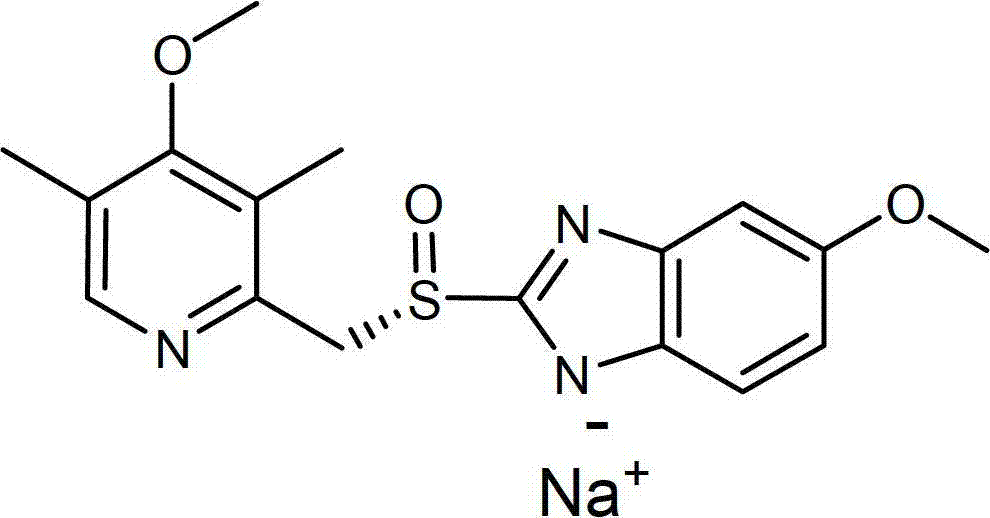

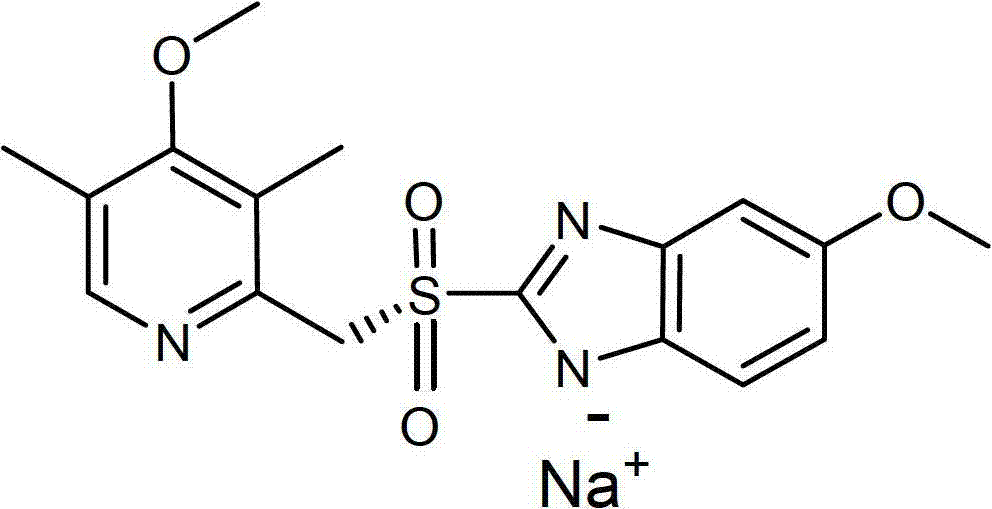

Preparation process of the sodium salt of esomeprazole

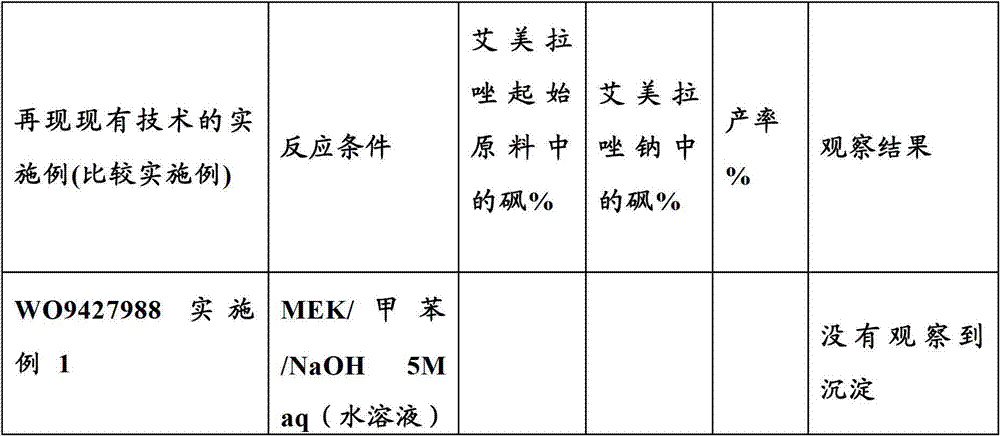

A technology of esomeprazole and sodium alkoxide, which is applied in the field of esomeprazole sodium, can solve the problems of unsuitable industrial scale preparation, difficult stirring, and difficult removal of residual solvent due to the degradation of crude substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: use the methanol solution of methyl isobutyl ketone and sodium methylate as solvent to prepare esomeprazole sodium

[0066] 30% sodium methoxide in methanol (4.7 mL, 25.3 mmol) was added dropwise to a solution of esomeprazole (8.5 g, 24.6 mmol; 2.2% sulfone) in methyl isobutyl ketone (60 mL) at room temperature. solution. The resulting slurry was stirred overnight. The solid was collected by filtration, washed with methyl isobutyl ketone (2×10 mL) acetone, and dried under reduced pressure at 50° C. to obtain esomeprazole sodium. Yield: 6.3 g (70%). Sulfone content: 0.33%.

Embodiment 2

[0067] Example 2: Preparation of Emmy using methyl isobutyl ketone / acetone and methanolic sodium methoxide Larazole Sodium

[0068] 30% sodium methoxide in methanol (4.7 mL, 25.3 mmol) was added dropwise to esomeprazole (8.5 g, 24.6 mmol; 2.2% sulfone, 4.7% R-enantiomer) in methylisobutyl solution in ketone (60 mL). The mixture was stirred for 15 minutes. Acetone (60 mL) was added over 30 minutes. The resulting slurry was stirred overnight at room temperature. The solid was collected by filtration, washed with acetone (2 x 10 mL), and dried under reduced pressure at 50 °C to afford esomeprazole sodium. Yield: 5.5 g (61%). Sulfone content: 0.17%. R-enantiomer content: 0.00%.

Embodiment 3

[0069] Example 3: Preparation of Emmy using methyl isobutyl ketone / acetone and methanolic sodium methoxide Larazole Sodium

[0070] 30% sodium methoxide in methanol (6.0 mL, 32.3 mmol) was added dropwise to esomeprazole (10.7 g, 31.0 mmol; 1.1% sulfone, 2.5% R-enantiomer) in methylisobutyl solution in ketone (75 mL). The mixture was stirred for 20 minutes. Acetone (75 mL) was added over 30 minutes. The resulting slurry was stirred overnight at room temperature. The solid was collected by filtration, washed with acetone (2 x 12.5 mL), and dried under reduced pressure at 50 °C to give esomeprazole sodium. Yield: 6.8 g (60%). Sulfone content: 0.06%. R-enantiomer content: 0.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com