Chain tensioner

A technology for tensioners and chains, applied to belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problem of identifying whether the initial positioning is released at a glance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

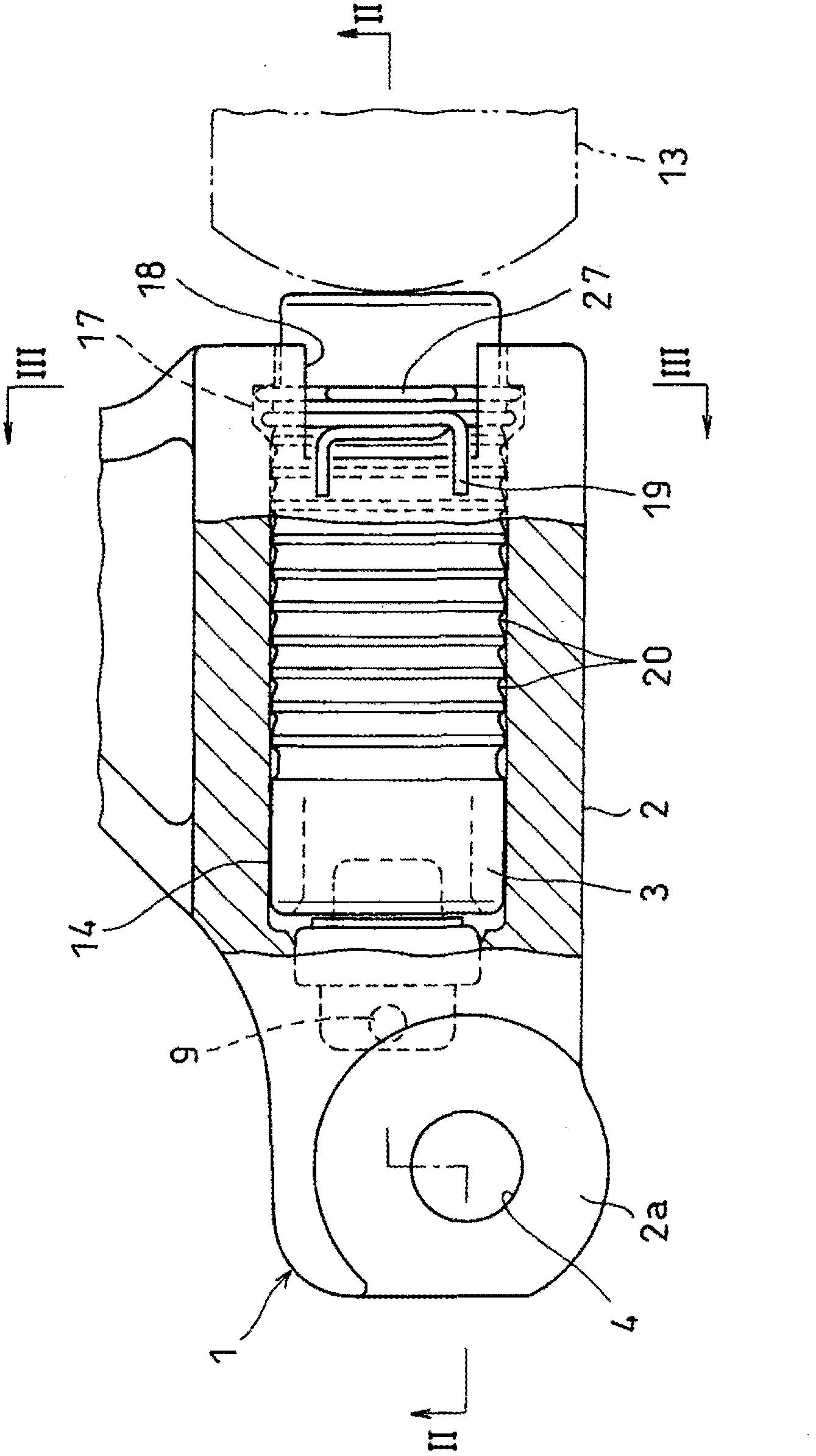

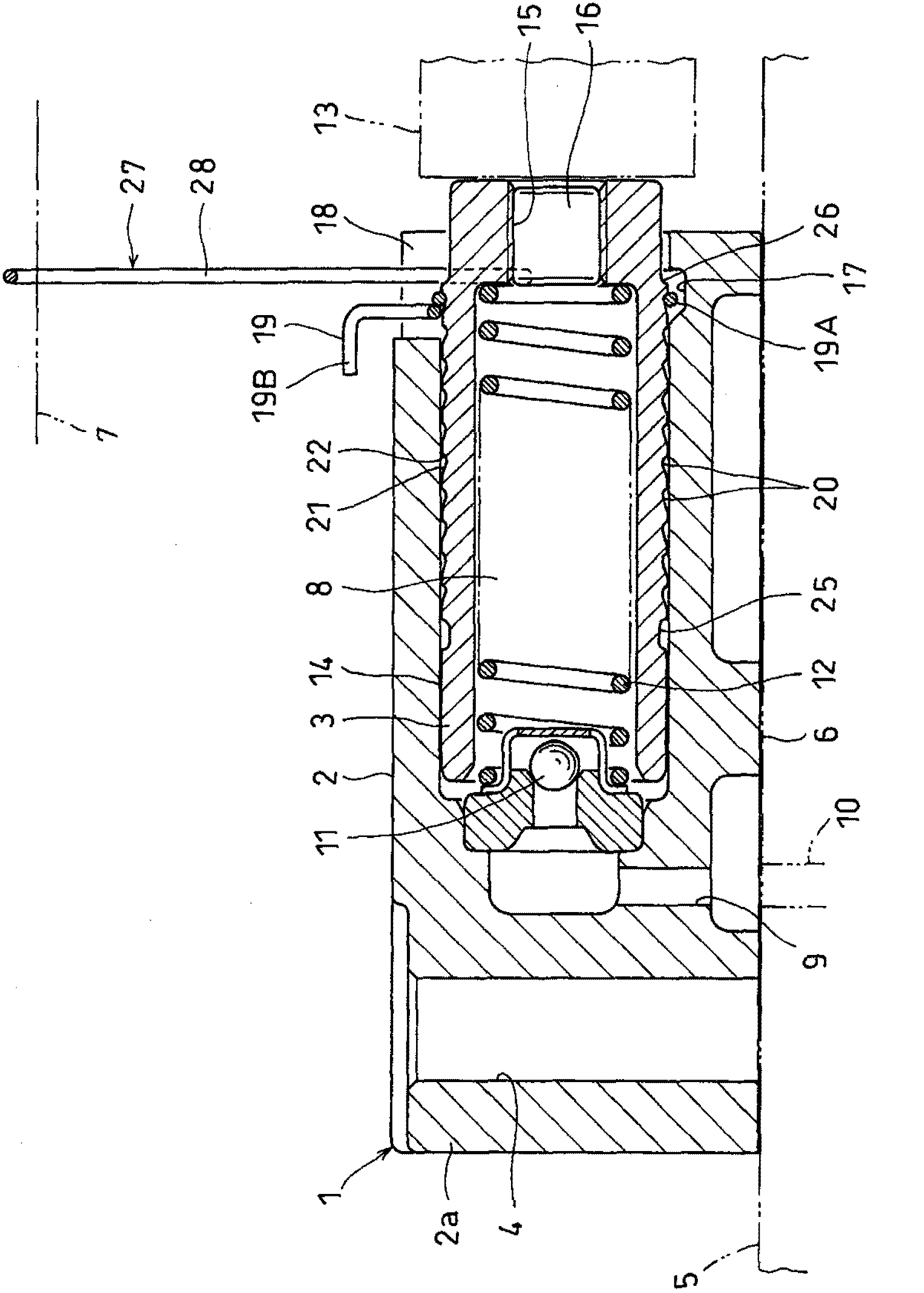

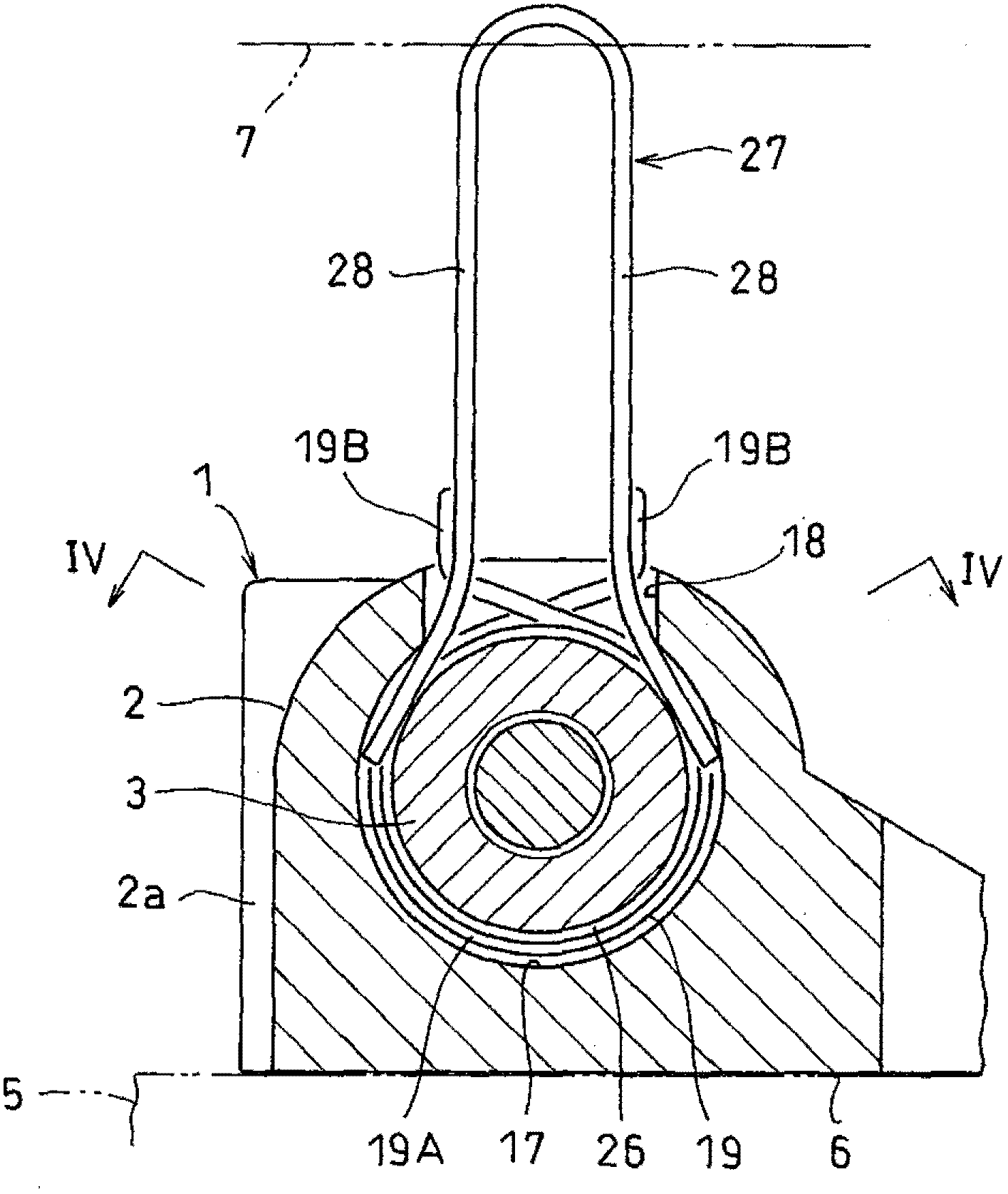

[0033] figure 1 The chain tensioner 1 which concerns on 1st Embodiment of this invention is shown. This chain tensioner 1 has a cylindrical cylinder 2 with one end open and the other end closed, and a plunger 3 inserted into the cylinder 2 so as to be slidable in the axial direction. The cylinder 2 is fixed to the side surface of the engine block 5 by screwing bolts (not shown) into the bolt insertion holes 4 of the mounting piece 2 a integrally formed with the cylinder 2 .

[0034] Such as figure 2 As shown, on the outer circumference of the cylinder 2, a support surface 6 supported on the side surface of the engine block 5 is formed. An engine cover 7 is attached to the engine body 5 so as to face a side surface of the engine body 5 with the chain tensioner 1 interposed therebetween. The cylinder 2 is made of aluminum in order to reduce the weight of the engine, and is molded by die-casting in order to reduce the manufacturing cost.

[0035]The plunger 3 is formed in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com