Internal-heating-type extruding device

The technology of extrusion device and heating device is applied in the field of heating extrusion device in plastic pipe extruder, which can solve the problems of uneven melting degree of particles, insufficient melting of raw materials, uneven particles, etc. The degree of uniformity, the high yield and the good quality of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

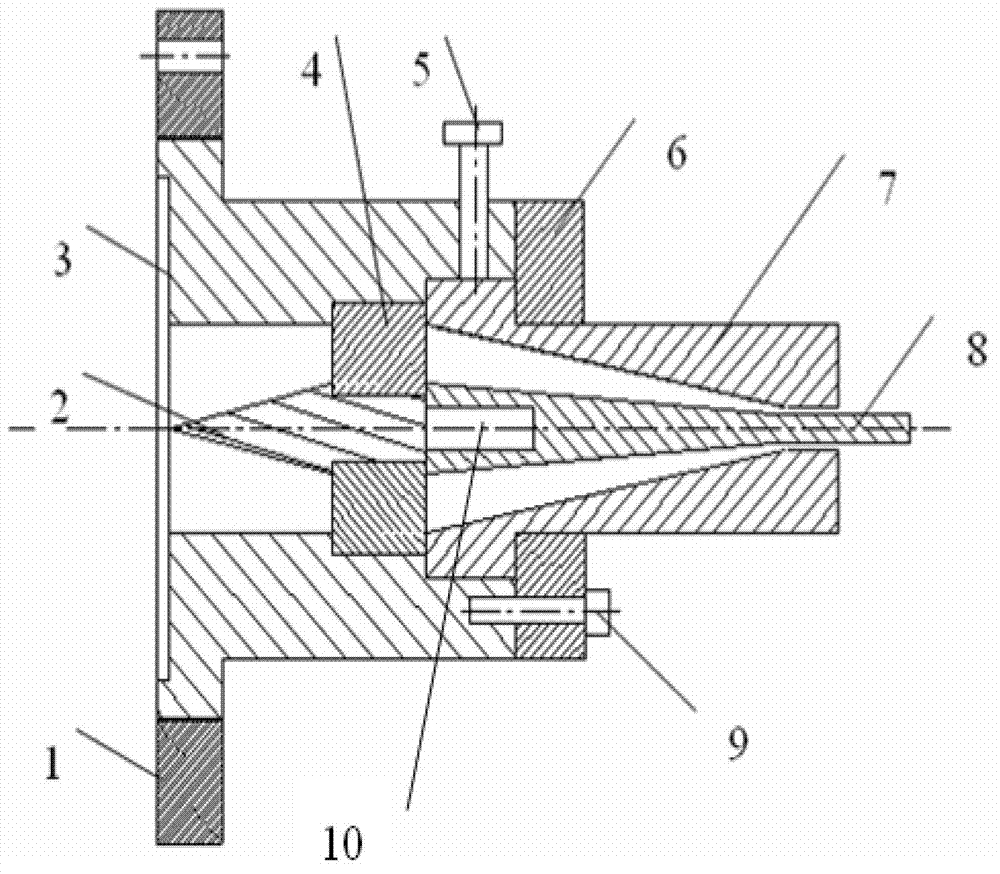

[0017] Such as figure 1 As shown, the present invention relates to an internally heated extrusion device, including a flange 1, a head connecting body 3, a gland 6, a die 7, a mandrel 8, a split cone 2, and a set of the flange Is connected to the outside of the handpiece connecting body 3, the die 7 is sleeved in the handpiece connecting body 3 and fastened by the gland 6, and the shunt cone 2 is fixed on the machine with a flat key 4 In the head connecting body 3, the core rod 8 is connected with the split cone 2 by bolts, and the core rod 8 is sleeved in the die 7 and fixed with the head connecting body by the fastening bolt 5, so A mounting hole is provided in the middle of the core rod, and a heating device 10 is arranged in the mounting hole.

[0018] The gland 6 and the head connecting body 3 can be fixed with positioning bolts 9, or other positioning elements such as positioning pins and positioning keys may be selected.

[0019] A temperature sensor is arranged in the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com