High melting point metal powder, solid propellant and its preparation process using boron powder

A preparation process and high melting point technology, applied in the direction of boron, boron/boride, etc., can solve the problems of difficult to obtain high-purity high-temperature elemental boron melt, difficult to break or spheroidize, difficult to boron high-temperature melt, etc., to achieve Strong surface activity, high spheroidization rate, and the effect of high spheroidization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

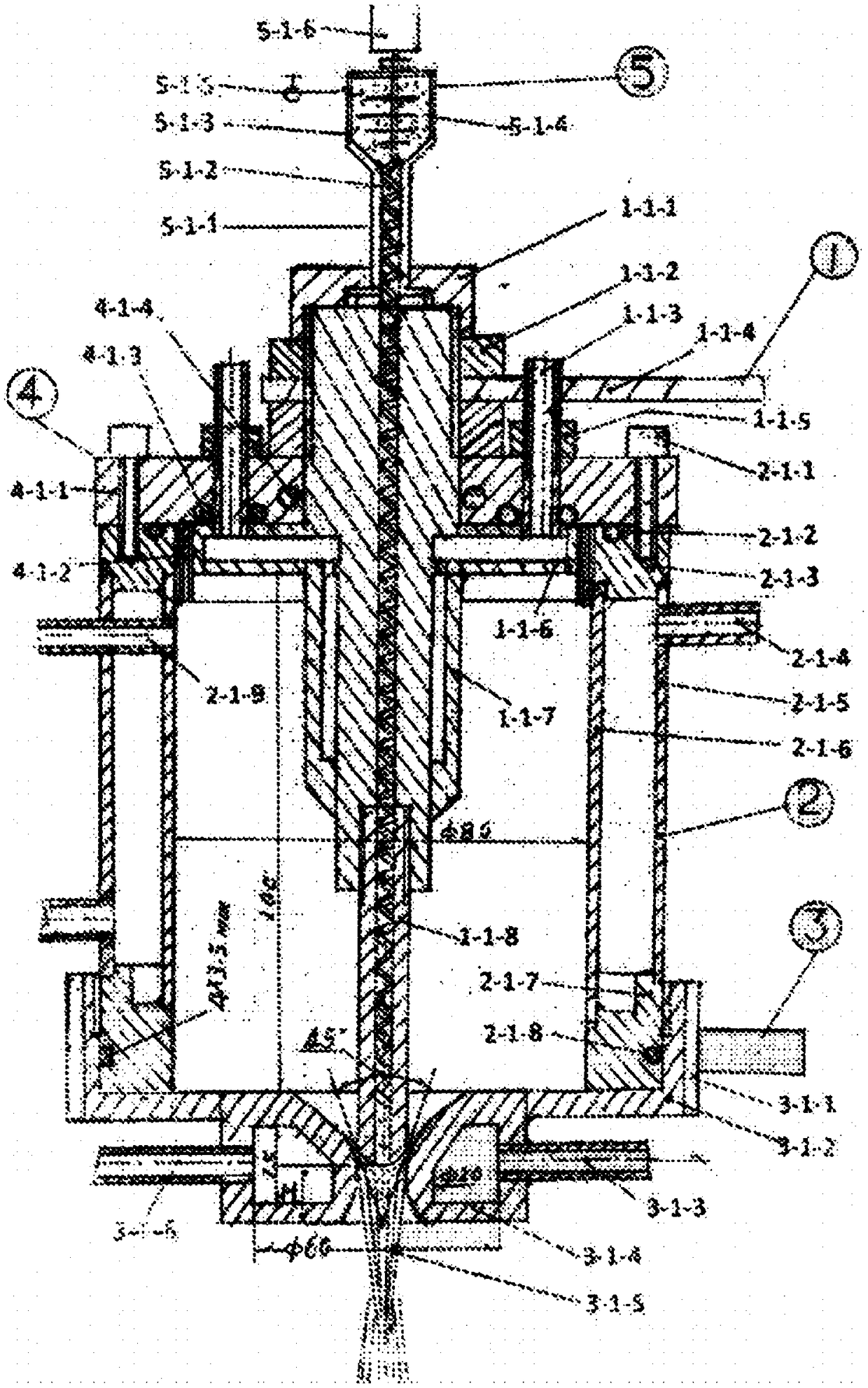

[0046] The present invention can adopt the invention patent of application number 201610248203.1, named a DC argon arc plasma powder spray gun and its preparation method. Using this hollow tungsten cathode ultra-high temperature argon arc plasma flame spray gun, the temperature is > 6000 ℃, it can pass non-spherical boron powder particles through the high-temperature flame continuously and rapidly melt to obtain molten boron without using a crucible The liquid droplets enable boron to melt at high temperature and ensure the high purity of the molten boron droplets. At the same time, powder can be fed continuously from the center of the spray gun.

[0047] A direct current argon arc plasma flame powder spray gun, which is composed of five parts: water-cooled hollow tungsten cathode system, gun body, combined anode, insulating part of flame spray gun, hollow screw powder feeder of flame spray gun, and adopts water-cooled hollow tungsten cathode at the same time The annular arc ...

Embodiment 2

[0086] 1. If figure 1 As shown, the DC argon arc plasma powder spray gun can also be called a hollow tungsten cathode ultra-high temperature argon arc plasma flame spray gun here. The following takes the non-spherical boron powder raw material as an example to illustrate its production process in detail.

[0087] 1. The function of the powder feeding system is mainly to solve the problem of continuously sending non-spherical boron powder into the powder spray gun. The specific process parameters and related equipment are as follows:

[0088] The system consists of the following components:

[0089] 1-1. Speed-regulating power supply 0-220V, 500W; 1-2. AC-DC dual-purpose speed-regulating motor for powder feeding; 1-3. Dial hairpin in the silo; 1-4. Raw material boron powder silo; 1 -5. Auxiliary air supply valve; 1-6. Hollow screw powder feeder.

[0090] The effect of each of the above parts has been discussed separately in prior patents.

[0091] 2. DC argon arc plasma powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com