Locomotive structure of high-speed train

A high-speed train and locomotive technology is applied to the locomotive structure of high-speed trains and the field of locomotive structures of high-speed trains, which can solve the problems of adverse effects on train operation stability, adverse effects on vehicle body strength, and adverse effects on surrounding environment, and achieves superior aerodynamic performance, The effect of increasing the field of view and reducing aerodynamic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

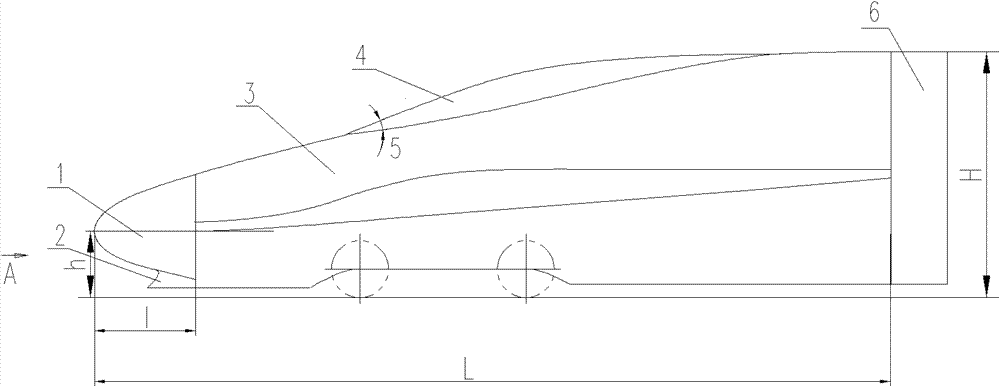

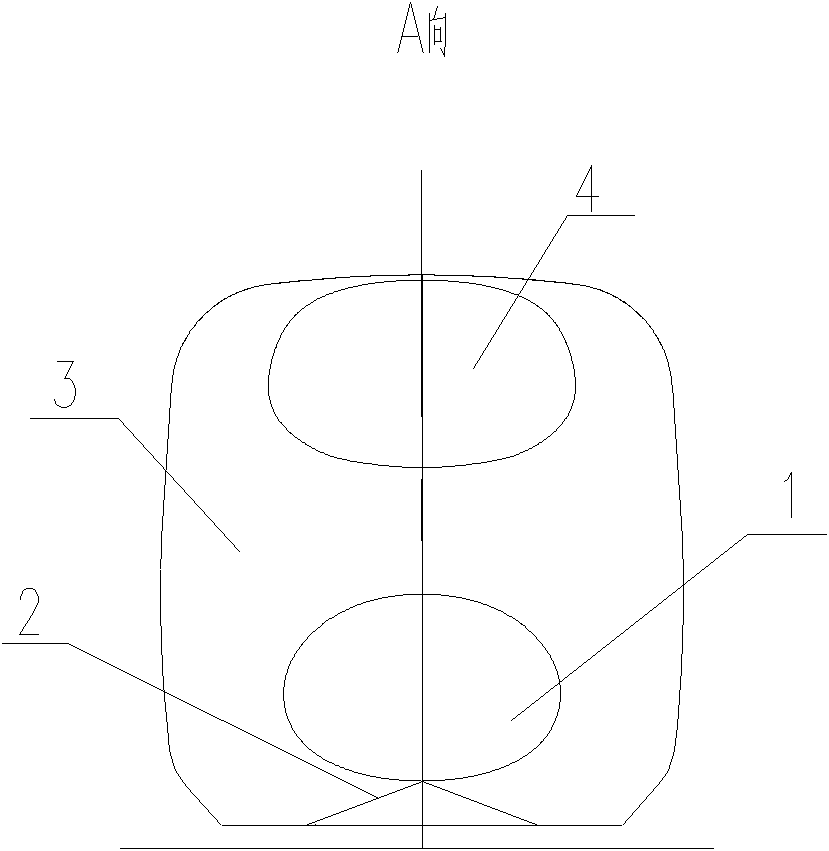

[0014] Such as figure 1 and figure 2 As shown, in the high-speed train head structure of the present invention, the overall shape of the headstock is streamlined, which helps to reduce air resistance. Specifically, the front structure is divided into four parts, namely the nose cone 1, the spoiler 2, the driver's cab 3 and the front window 4, and the transition between each component is smooth, and the front part and the section 6 of the car body are smooth. Transition, in addition, the structure of the front of the car also includes structures such as observation windows (not shown in the figure) located on the side walls on both sides of the driver's cab 3, and lights (not shown in the figure).

[0015] Wherein, the nose cone 1 is the head of the front of the car, and the surface of the nose cone 1 is a rotating body, which is formed by rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com