Hollow glass

A hollow and glass technology, applied in the direction of building components, buildings, building structures, etc., can solve problems such as difficult quality assurance, increased costs, and unreasonable stress conditions, and achieve the effect of avoiding secondary environmental pollution and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

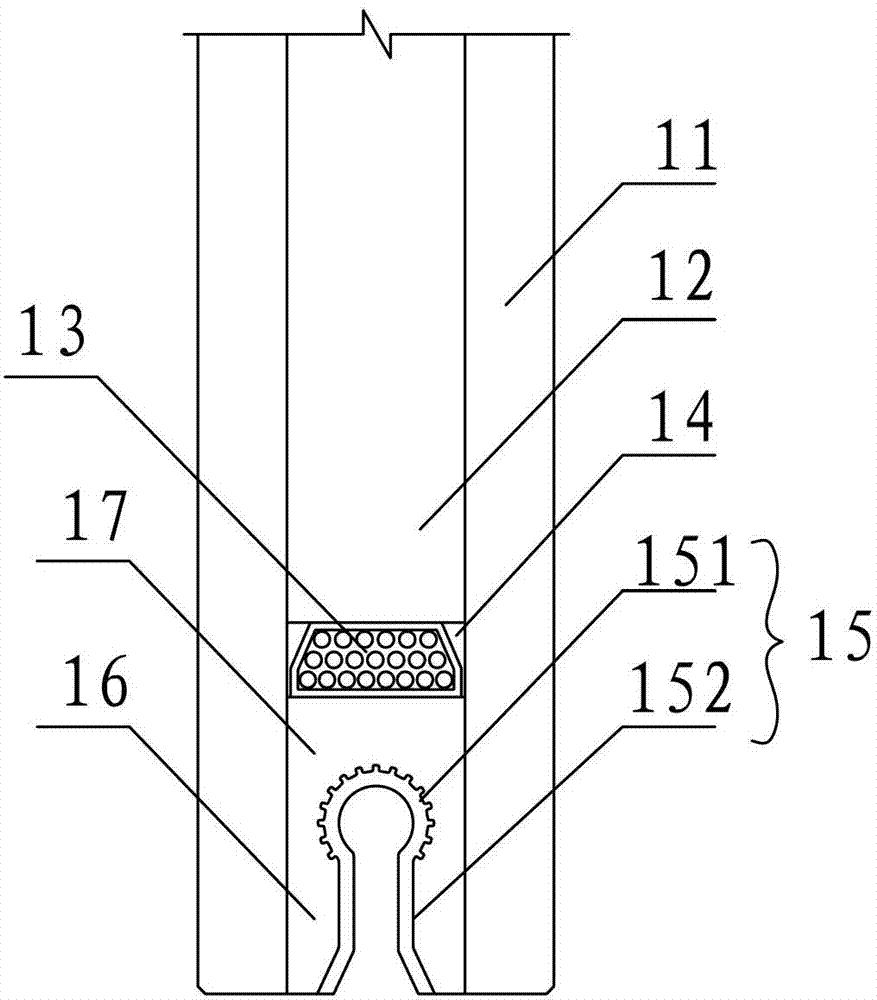

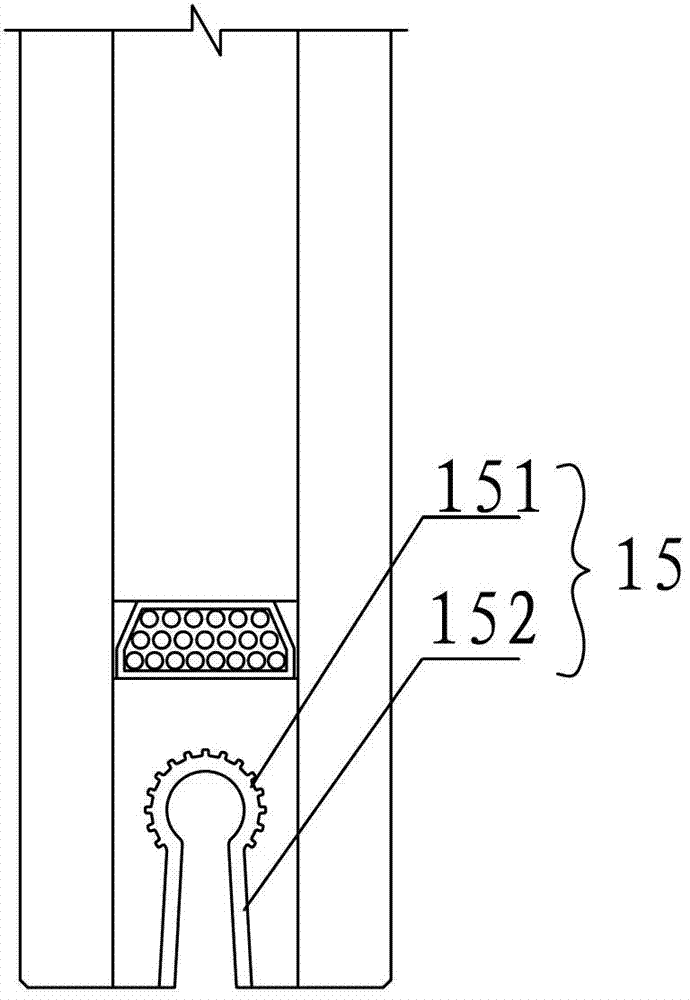

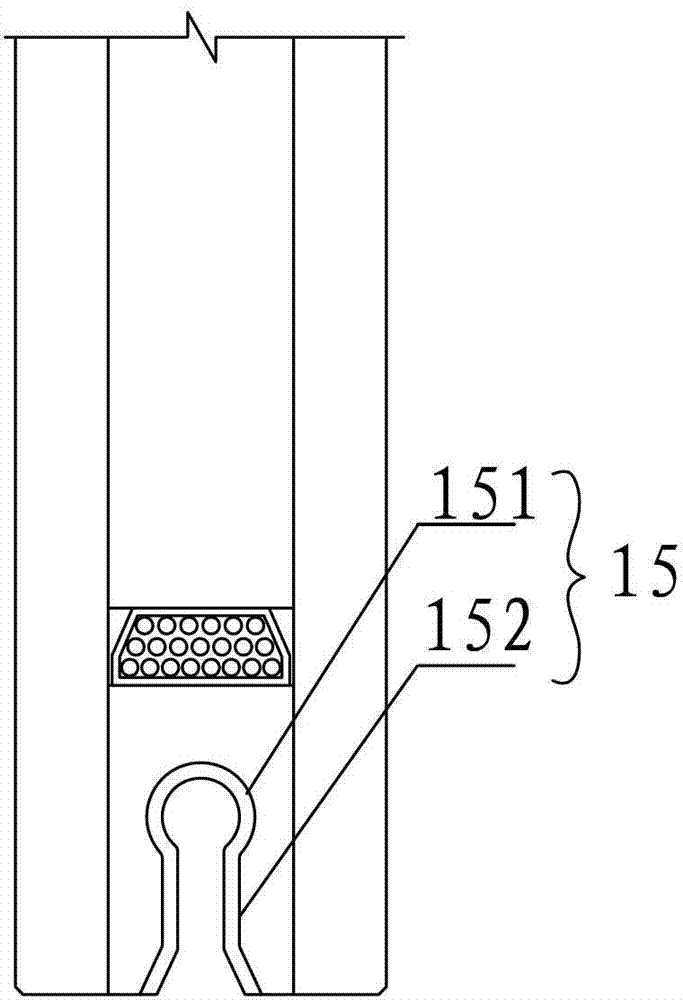

[0020] The present invention mainly includes two pieces of glass 11, a hollow layer 12 formed between the glasses, a spacer frame 13 filled with a desiccant, an inner layer sealant 14, a metal profile 15, and an outer layer sealing structure adhesive 16.

[0021] A spacer frame 13 with a desiccant is arranged around the two pieces of glass 11, and an inner sealant 14 is applied on both sides of the spacer frame 13 for sealing and fixing. The space is exactly the hollow layer 12 . After the inner layer sealant 14 is solidified and fixed, a groove 17 is formed between the outer side of the spacer frame 13 and the two pieces of glass 11, and the metal profile 15 is placed in the groove 17, and then between the groove 17 and the metal profile 15, a groove 17 is formed. Put the outer layer sealing structure glue 16 in the gap.

[0022] Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com